By Prabhat Khare

The India mobility network has about a quarter billion registered vehicles which are the basic sources of pollution resulting in serious damage to the environment. The damage is not only in terms of air pollution but there are also other environmental degradations which happens all through the complete life cycle of vehicles. So, it is necessary to monitor and regulate the lives as well as life cycles of Automobiles, and plan to properly discard them at the end of their useful life. The other environmental damages (land & soil degradation, groundwater contamination etc.) caused by them during their life cycle are also equally important & as serious as air pollution. While it is well known that many harmful gases (HC, NOx, Sox with PM) are formed as a byproduct IC engine operations imposing serious effect on human health, the other less known issues related to many hazardous materials, chemicals & metals coming out of these vehicles over the time causing similar or more serious impact on total ecology of human surroundings.

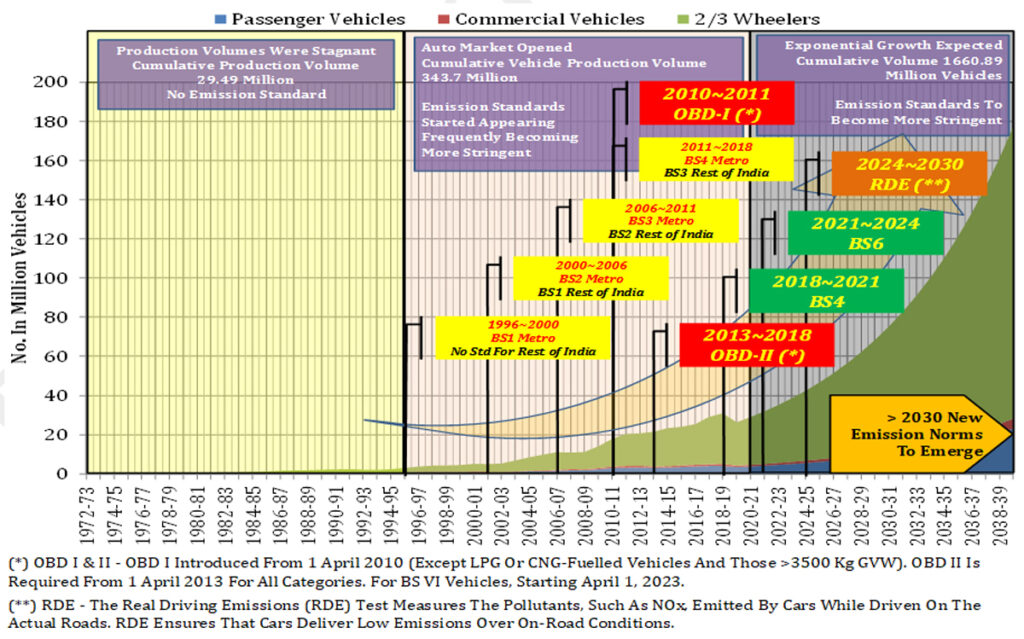

To control the release of these harmful exhaust gases into the environment various countries have initiated and implemented different pollution standards for the Automobile manufacturers according to the vehicle type to keep the air quality clean. For example, Environmental Protection Agency (EPA) in the United States government, European Union Research Organization (EURO) in Europe have framed strict rules for vehicles to limit the toxic exhaust emissions releasing into the environment. By taking the EURO emission standard as reference Central Pollution Control Board in India has implemented Bharat emission standards (BS Norms) and it is updating its regulation at regular intervals of time. The introduction time limes of various emission norms in India with the rise of production volumes are shown below:

The graph clearly shows that with exponentially rising production volumes, bringing more & more vehicles on the road, stricter emission norms with quicker up-gradation have also been brought in India, for two reasons – first to avoid degradation of environment & second with an open market scenario, to restrict various automobile MNCs coming to India and dumping their obsolete technologies to make profit from the Indian market.

But more importantly, when newer vehicles with better technologies started coming on the road, the time was ripe to bring a set of regulations to remove the older vehicles from the road in a phased manner and hence the current “Vehicle Scrappage Policy 2021” by GOI is a well-timed & a positive step in the right direction. The policy has perfect timing because of three reasons – first for the disposal of older vehicles, which have more toxic pollutants coming out of their old engines and their now obsolete technology, second because of older technologies only these vehicles may be highly unsafe on current roads, expressways and high speed motorways, and thirdly, if numbers of vehicles are not controlled on road by making these old vehicles off-road, traffic-related issues as well air/ land pollution cannot be managed.

In order to reduce the environmental degradation, while the GOI controlled the fuel quality, the main contributor for ICEV performance, it also promoted alternative fuels like CNG, Bio, Electric, Hybrid, Hydrogen/ Fuel Cell etc. as well as on many other interrelated fronts. The new “Vehicle Scrappage Policy” is one of the very critical policy in the same direction which will have many positive impact like improving vehicle performance, reducing the precious oil import bill, it will also help in reducing environmental pollution as well as it will also provide incentives to people for buying new vehicles post disposal of their obsolete vehicles. However, such recycling policy should be based on the vehicle’s performance rather than its age, as & when it starts performing continuously poor, then it must be disposed of by diverting it to an organized & professional recycling setup, which will pave way for a modern “Vehicle Recycling Industry” which must never be called “Vehicle Scrapping Industry”.

End-of-Life for Vehicles

Regardless of its age and its weight, a vehicle is mostly made out of about 75% metal, both ferrous and non-ferrous while the remaining 25% of the vehicle weight results from tires, plastic, rubber, plastic, gases, glass, fabrics, fluids such as oil, antifreeze, lubricants, and gasoline/ diesel, as well as various electronic components/ circuitry having heavy, rare/ rare earth metals. With time these components decay and when the vehicle becomes unusable, it is said to have reached at its end of life. For further clarification a vehicle may also be considered a waste under many other scenarios e.g. discontinuation of a model, accident, damage ad or non-availability of spare parts. However, vintage vehicles do not fall within the scope of the legislation. Vintage vehicles include historic vehicles or vehicles of value to collectors or intended for museums, kept in a proper and environmentally sound manner, either ready for use or stripped into parts.

Understanding Vehicle Recycling: Cradle to Cradle

While “scrapping of a vehicle” literally means that old vehicles have reached their EOL or damaged vehicle (accident, natural calamity, or by any other reason) and are not road worthy. Such vehicles are barred by RTO for registration and hence are sold as junk to scrap dealers. Now, vehicles can also become road unworthy because of many other factors e.g. their technology becomes obsolete, their spares parts are not available or they develop some irreparable technical snag etc.

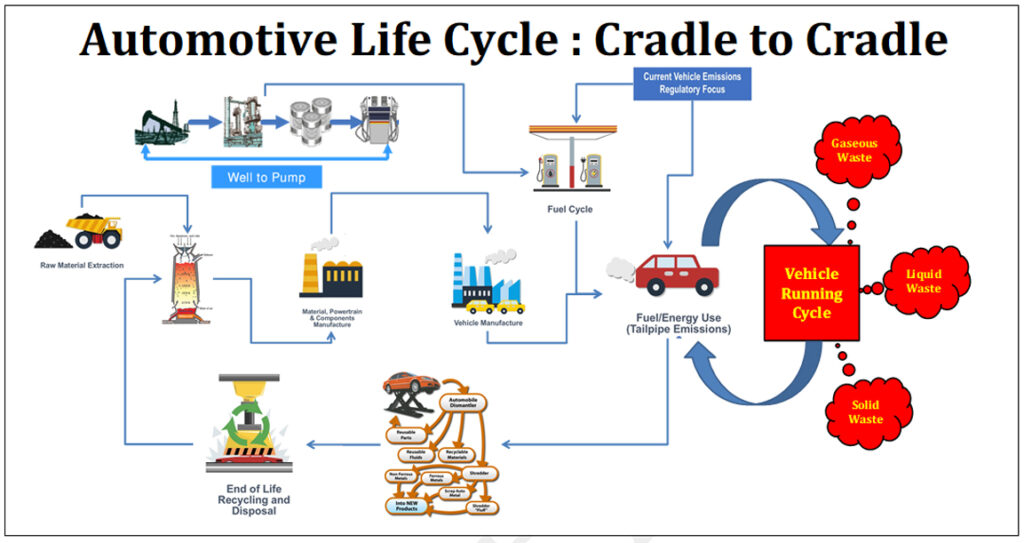

Yet unlike any other scrap items, these road unworthy vehicles still are composite and complex amalgamation of various materials, chemical, liquids, gases (many of them could be toxic) which if handled properly can be effectively recovered from the “Scrapped Vehicle” and can be reused. Hence it is important to understand the term “RECYCLING” in the context of vehicles to which the current “Vehicle Scrappage Policy 2021” of GOI refers. “Recycling” can be termed as bringing maximum materials back to the cradle from it all began.

As stated above, an automobile has a wide & complex range of materials (see picture below) used in its creation which depends upon the make and models and hence as such it is very difficult to generalize them yet Wikipedia (https://en.wikipedia.org/wiki/List_of_auto_parts) gives a general listing of materials uses in any automobile.

Most of these items can be successfully recycled/ refurbished/ reused if handled carefully and can be given a new lease of life so that either they could be reused in the secondary market as spares or could be utilized in some different forms & in different applications. Alternatively, they could be recycled into their basic raw materials and could be a feed to the steel, aluminum, plastic, copper, and brass manufacturing industries. The primary goals of the vehicle recycling industry are to salvage these components from an old and used automobile. Below given chart is an approximate assessment of recyclability of an average automobile.

Current Scenario in India

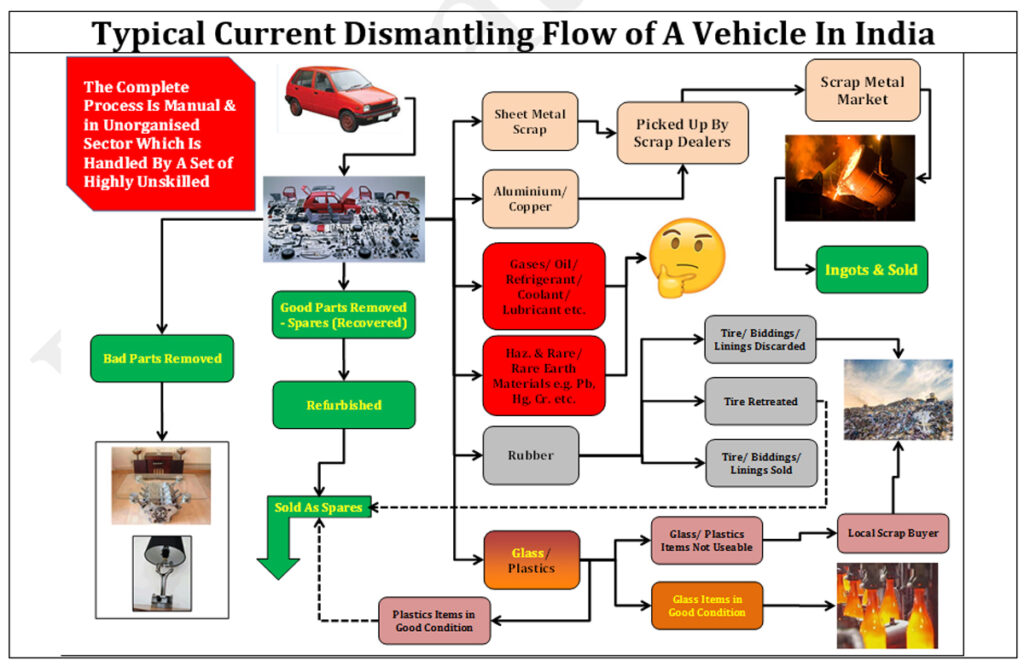

Every year, vehicles that reach the end of their useful life, end up as discarded vehicles. Unlike advanced countries where the system of automobile recycling has been in practice for quite some time, in India often these vehicles are abandoned or stockpiled at poorly managed local garages. Unfortunately for want of any reliable database, there are no real numbers available which can indicate as to how many vehicles reach the end of their useful life annually. However, another challenge in India is that once a vehicle becomes unusable, it is never properly processed for recovery of the reusable or recyclable materials as well as disposal of balance materials. Without proper processing, scrapping, and recycling, the number of such vehicles have only increased year after year and have become a liability for the owners who tend to abandon them on open land or sell them to a regular scrap dealer who is neither equipped nor aware of their disposal methods causing serious environmental damage leave aside the safety concern in handling it.

Fortunately, with the proper training, facilities, tools and knowledge to process discarded vehicles, hazards can be properly managed as well as vehicle components and parts can be recovered for their scrap metal value while good parts can be salved to be used as regular spares. A properly managed discarded vehicle reduces risks to workers, public health, and the environment; lowers disposal costs; saves landfill capacity, and creates opportunities to recover valuable resources and earn revenues from dismantling and scrapping operations.

Unfortunately, till now, India had neither the infrastructure nor the proper regulatory mechanism for efficient disposal of these end-of-life vehicles and current way of handling old vehicles had been very crude as shown in below given in flow chart.

Note: Without a proper recovery system installed, a wide range of materials, including rare earth & rare metals to low-grade used oils have full possibility of seeping in the ground contaminating the soil and ground water. Whereas Industry sources indicate that if new age recycling methods are adopted, a normal sedan can help to recover materials equivalent to 2,500 kilograms of iron ore and 1,400 kilograms of coal; reduce the release of 1,000 kilograms of carbon dioxide, and save more than 1 megawatt of energy. In the case of a motorcycle, the corresponding gains are approximately one-eighth of the gains of a car. The accrued energy savings are essentially due to the melting of scrap, rather than smelting ores. Recycling one kilogram of aluminum saves 14-kilo watts of electrical energy, compared to producing virgin metal from bauxite.

Need to Improve Indian Recycling Plants

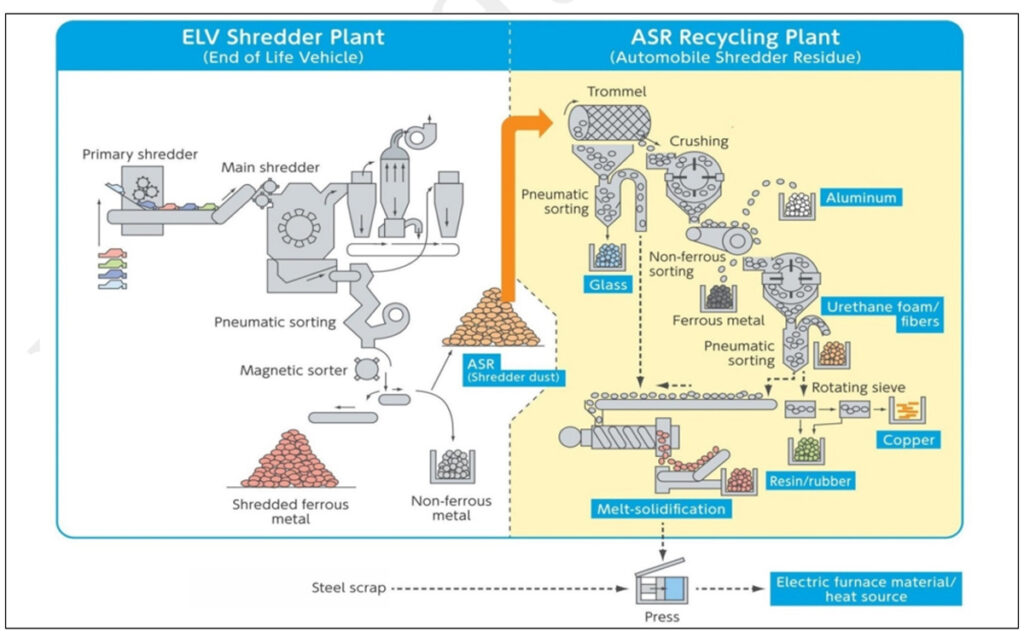

Broadly, a state-of-the-art dismantling process could be summarized as two stage process, the first stage process which is what generally happens in India as explained above. But unfortunately this happens in a very unscientific & un professional manner and need to be improved a lot especially when it comes to recoveries of liquids, gases, lubricants & many of the hazardous components which need to be handled carefully to prevent their release in surroundings and they must be stored properly before being reused or recycled. The whole proves needs to be made more mechanized & automated.

Post above dismantling in the second step, the vehicle needs to be sent to a recycler or the shredding facility known as ASR (Automobile Shredder residue) plants which currently is not available in India. These capital-intensive plants have complex material separation operations. The shredder pulverizes the vehicle, which is then sent by conveyors to sophisticated metal separation technologies, including magnetic separation, eddy current, laser, and infra-red systems. Such recovery plants then become raw material feedstock for steel mills, electric arc furnaces, aluminum, and other non-ferrous metal smelters. A simple flow chart of these plants is shown below:

- As vehicle registration data available with various RTO is only cumulative and has not been corrected for scrappage, phase-out, and transfers as well as with no records of de-registration, it is not possible to estimate the precise number of old vehicles by age in India. Thus it is, therefore, always a doubtful estimate on the number of vehicles. But with the advent of the VAHAN database launched in July 2011 the database in getting created which indicates that as of Apr’2021 there is a total of 290.85 Million registered vehicles in India. It is expected with the ongoing implementation of HSRP (High-Security Registration Number Plate), this number will become more accurate as the time passes. A deeper effort is needed to correct the entire national database, which more digitalization.

- Infrastructure & Technology to Handle the Large Volumes: The current infrastructure for vehicle dismantling process in India is in a pathetic state are mainly local garages which with the addition of more such garages in the area grows into an unauthorized disposal market e.g. Mayapuri (Delhi), and Shivajinagar (Bangalore). These local garages functioned smoothly till there were limited numbers of old age vehicles for scrapping but as the volumes of complex new-age vehicles grew they find it difficult to handle these vehicles. India needs to maximize the dismantling centers around the cities with a higher concentration of vehicles; good connectivity, and logistics facility. These recycling facilities must also be state-of-the-art facilities to recover high-quality metals, oils, and other materials as well as waste treatment. The system must have a team of a properly trained technician to assess the reusability of parts which must be dismantled from the vehicle, cleaned, tested, inventoried, and stored in a warehouse until sold.

- Tracking, Identification & Accountability: Once the parts are dismantled from old vehicles & are sold as spares, like any global markets, having fairly organized business, there must be proper traceability of these parts to track their performance of vehicles for retaining their roadworthiness.

- Handling of New Age Electrical, Hybrid Vehicles: With the new focus of Govt. on electrical & hybrid vehicles, as new means of mobility is evolving and rule the mobility world in coming few decades & with times when these vehicles reach their EOL, these vehicles would also be coming for proper disposal (aging time may be different than what has been set for current age vehicles but they will certainly be aging) and will be coming for their disposal due to age, road accident, damage due to natural calamity, etc. and hence any vehicle recycling facility must also be planned to handling these new-age non-ICEVs. The major concern is in handling the large set of spent Lithium-Ion Batteries (LIB) which needs to be taken out of the vehicle when their capacity reduces by about 25%. The typical recycling process for Li-ion batteries will get Lithium out of old batteries as more than 99% of Lithium can be reused. The by-products of the recycled batteries will depend on the process, the battery chemistry and many other factors. As the recycling of Li-Ion batteries increases, it will help to bring down the pricing of the batteries further. This will in turn improve the adoption of EVs.

- Landfills: Although India already has well organized and controlled landfill site management system in place for Hazardous Wastes yet requirement of Automobile waste needs to be studied and if needed special landfill site may be developed.

- Development of Skilled & Trained Manpower: The Govt. may think of creating a totally independent Skill Council for this area and to provide special training to people in dismantling the new age automobiles in a systematic an technologically sound matter which tries to maximize the recovery of reusable materials from these vehicles which have reached at the end of their lives.

Epilogue

We need to learn from shipbreaking Industry in India which began in Kolkata and Mumbai in the 1910s when environmental concern & human safety were in primitive stage and beginning with 1980s when the world started seriously considering India as a destination for recycling old vessels and business grew to whooping 6000 crore per year. Unfortunately is also brought many social & environmental issues which have been well recorded in many studies.

Serious impact of plastic debris contaminating the soil leading contamination of food chain (bio-magnification), degradation due to heavy metals. Unlike ship breaking facilities which are far away from human habitat the automobile recycling facilities will be nearer to human habitat and any improper operations will have serious impact on surroundings. Alang is facing a severe water crisis due to groundwater depletion & contamination so is the frightening list of diseases prevalent in that area; & we can to afford to make many such Alangs across the country.

The author is Director, KK Consultants, a BE (Electrical), Gold Medalist, IIT Roorkee, Life Member of National Safety Council, a BEE Certified Energy Manager, a Lead Assessor For ISO 9K, 14K, 45K & 50K and an industry expert with work experience at Tata Motors, Honda Cars and Ashok Leyland.

References:

- Vehicle Recycling, Toyota Motors, April 2017

- Development of Scientific Recycling Of End of Life Automobiles In India and The Role of Research & Development, Indian National Academy of Engineering, November 2015

- Processing End-of-Life Vehicles: A Guide for Environmental Protection, Safety and Profit in the United States-Mexico Border Area, July 2017

- Auto Salvage Recyclers Environmental Self–Audit Workbook, Indiana Department of Environmental Management, January 2017

- https://www.cseindia.org/what-to-do-with-old-vehicles–10379

- https://www.mahindraaccelo.com/greater-noida.php

- https://www.timesnownews.com/auto/car-news/article/mahindra-signs-mou-to-offer-first-of-its-kind-vehicle-scrapping-solution-in-india/742095

- https://www.downtoearth.org.in/coverage/bare-facts-21345

- https://www.eea.europa.eu/signals/signals-2017/infographics/range-of-life-cycle-co2/view