Tippers is considered a most critical vehicle segment to drive infrastructure development. Designing tandem drive axle suspension for a tipper in the Indian context is always a challenge considering the wide range of usage, loading pattern and maintenance practices. The basic difficulty is that a tipper may be configured by the OEM for a particular use, but the operator may put into a different use after purchasing it. This is more prominent when the OEM sells the tipper chassis instead of a fully-built tipper. Most of the operators view reliability as most important purchase driver, and the ability of OEM supporting in case of any difficulties is the next important aspect. Challenge lies in maintaining the ride quality in both unladen and laden conditions as well. One more challenge is to provide the needed articulation without losing traction.

The current systems are prevalent since inception. They have leaf spring as the most critical component and most vulnerable as well. The cheapest version of tandem the drive axle suspension system uses four spring system linked with equalizer bar and many linkages. A higher version uses the inverted leaf bogie suspension system with torque rods for axle placement at the bottom and A-frame or straight torque rods at the top. A few of them use rubber bolsters and anti-roll bar depending on the needed articulation. The bogie suspension system is useful to carry heavy loads as compared to the four spring system but is relatively heavier.

Hendrickson International has mastered the drive axle suspension technology over the years with the first such system introduced as early as 1928. The one-millionth advanced walking beam suspension was produced in 1977 wherein the leaf pack was eliminated. A lighter version HAULMAAX for haulage application was introduced in 2002 and the heavy duty version HUV was introduced in 2010. TATA Autocomp Hendrickson Suspensions Pvt. Ltd., with its extensive knowledge of local operating conditions, has customised this HUV suspension to suit Indian operating conditions and maintenance practices. A new customized version of the suspension called ULTIMAAX provides a unique combination of light weight, best ride quality in both laden and unladen condition, low or negligible maintenance with high reliability.

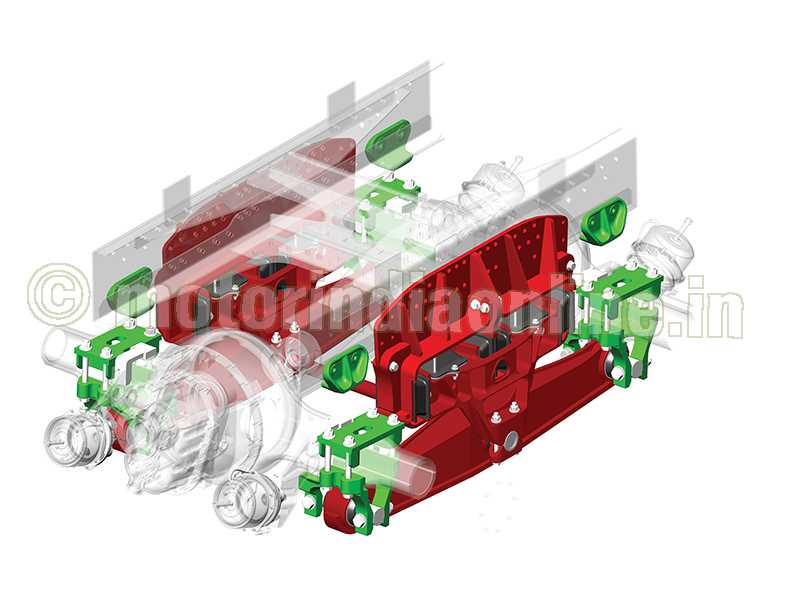

In this innovative product, rubber suspension (ULTIMAAX) consists of rubber spring (steel leaf springs are replaced by rubber springs), walking beam and frame saddle assembly. In the rubber suspension, not only weight is reduced but ride quality, safety and durability are enhanced.

In addition to its excellent durability, ULTIMAAX delivers enhanced stability, handling and ride quality even in the most severe-duty environments where vehicles encounter harsh and unexpected ground conditions. The integration of Hendrickson’s proven walking (equalizing) beam technology with its patented progressive rate spring provides a balance of loaded stability and unloaded ride quality even in the most rugged environments.

For outstanding stability, driver comfort, equipment protection

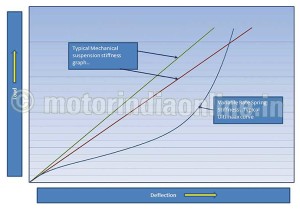

Normally operating as an off-road application, tippers get overloaded. To address this, the existing suspension needs to have more number of leaves and an anti-roll bar. These additions not only increase the weight of the existing rear suspension but also increases its stiffness. The increase in stiffness in suspension in turn increases vehicle vibration during unladen running. In the tipper segment, as the vehicle runs 50 per cent time in unladen condition, the increase in vibration leads poor ride quality and reduced life of the chassis-mounted vehicle parts. In this rubber suspension design, suspension stiffness is made variable to get low suspension stiffness at unladen to get good ride quality and high stiffness at overload to get good stability.

Aside from providing a reliable system for maximum uptime, ULTIMAAX is a low maintenance system that contributes to reduced life cycle costs and less downtime in the following ways:

Maximise Mobility and Traction (In extreme environments)

The ULTIMAAX system is capable of extremely high articulation for demanding job-site or off-road conditions. When loaded, ULTIMAAX delivers up to 17.5 inches of diagonal wheel articulation to keep load on all drive wheels. The equalizing beam design itself contributes to excellent traction, utilizing a central pivot point to distribute load between the axles and help the tires to maintain contact with the road or worksite surface.

|

The ingenuity behind the UMX system can be found in the unique rubber spring design. Rubber shear springs carry most of the vertical load in the empty condition, resulting in a soft ride. As the load increases, the progressive rate springs compress more to carry a greater portion of the load, increasing the stiffness of the suspension without causing an abrupt change in ride characteristics. UMX’s unique balance of empty ride quality and loaded stability not only helps to protect the driver but also to cushion the load and protect the chassis, cargo and body equipment from excessive vibration and road shock due to potholes and other irritants on the road. |

|

In the empty condition, the suspension rides primarily on the diagonal rubber shear springs, which help to absorb road inputs and fore / aft shock for outstanding ride quality. |

|

|

|

• Superior ride results in reduced road shock and vibration to the vehicle, which contributes to longer service life of the cab, chassis and body equipment • No lubrication requirements • Progressive rate springs provide long service life and are easy to replace • Bar pin end bushings designed to extend service life and reduce re-bush time |