India has made its intentions clear in terms of moving to cleaner energy and is not too far behind in the evolution of EVs. From an abrasives’ perspective, the conventional components will be replaced by newer ones like magnets which require grinding. And in this space, Grindwell Norton has certainly taken the lead, reports Rajesh Rajgor

Grindwell Norton, the Indian arm of Saint-Gobain Group, was founded in 1941 as Grindwell Abrasives. The company is a leader in the abrasive segment in India. With manufacturing plants at Bangalore, Baddi, Mumbai and Nagpur, the company with its flagship brand ‘Norton’, provides cutting-edge innovations and technologies for the automotive industry, including OEMs, component manufacturers and the aftermarket. Today, Grindwell Norton Abrasives boasts of a wide portfolio of cutting, grinding, blending, finishing and polishing solutions for all markets, materials and applications with the most advanced and affordable technology.

Serving automotive and industrial OEMs, the company provides solutions across a wide spectrum of applications and materials. “From large OEMs to the top 100 automotive component manufacturers and the automotive aftermarket, we cater to all of them. We have a very wide presence in India and service our customers directly and also through a 1,000+ distribution network spread across the country. Additionally, we have a 200+ strong sales team that is based all over India and is backed by a strong application engineering team that works with the customers to recommend the best possible solutions optimizing grinding performance and cost,” shares Hari Singudasu, Vice President-Abrasive, Grindwell Norton India.

Grindwell Norton launched a new range of surface finishing compounds under the brand ‘Farecla’ in Q4 2020. Elaborates Hari: “Saint-Gobain acquired Farecla, the UK-based company to leverage their expertise of abrasive grains, a key input for manufacturing of compounds, and Farecla’s knowledge of manufacturing process and applications. The product offers surface finishing solutions across various surfaces, ranging from segments like aerospace, automotive, woodworking, etc. This will further strengthen our positioning in the automotive segment and particularly in the automotive aftermarket by enabling clients to improve productivity as well as quality of finish.”

Tailor-Made Solutions

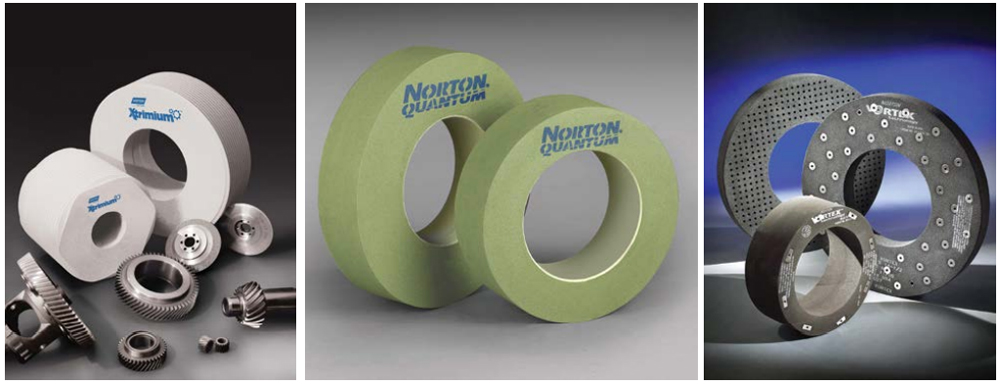

One of the best capabilities a company can possess is the ability to custom design solutions or products that deliver the best performance and cost to the customers that it closely works with. Says Hari: “A lot of MNCs and leading Indian companies prefer good, high-end technologies that deliver the same level of performance and finish as is seen in developed countries. Being part of a large global organisation gives us a head-start in meeting these expectations better and faster than any competition. Our application engineers are present at the site of the customers to understand their requirement even before a new plant is fully commissioned, thus ensuring availability of the right products and solutions right from the word ‘go’. Today, we have the complete portfolio in abrasives ranging from roughing, grinding to finishing and polishing. We have specialized products such as Quantum, Vitrium 3, IdealPrime, Vortex and Xtrimium, which are widely used for grinding gears, bearings, transmission and engine parts in addition to automobile body sanding, paint polishing and glass pre-processing,”

Serving Aftermarket and Electric Vehicles

Having a strong, full range portfolio of products with across India reach is essential for anyone to be successful in this segment. “We have a separate, dedicated division that caters to the needs of the aftermarket. We are approved by most of the large OEMs in India and cater to their body shops. We train the technicians in the body shops to help them to choose the right process and combination of products to give the required finish at lower cost,” Hari explains. India has made its intentions clear in terms of moving to cleaner energy and is not too far behind in the evolution of EVs. From an abrasives’ perspective, the conventional components will be replaced by newer ones like magnets which require grinding. Also, the potential for tapes and films, part of world-wise Saint Gobain Abrasives and Composite Systems, will see a significant increase. “We are prepared with products and solutions for the transition to EVs which goes well with Saint Gobain’s purpose to make the world a better home,” Hari adds.

Making the World a Better Home

Post the pandemic, sustainability has assumed even much higher importance than before. With the US now recommitting to the Paris Climate Change accord, the world is expected to take steps to reduce emissions. As a company that significantly values social responsibility and commitment to protecting environment, Saint Gobain has recently unveiled its purpose – ‘Making the World a Better Home’. Hari says that SG Abrasives in India is well-poised to help the customers and the country in their journey towards sustainability with solutions that would consume lesser energy in manufacturing while helping the customers to do more with less. He elaborates: “Together with and for our customers, we design, manufacture and distribute materials and solutions that have a positive impact on everyone’s life and provide well-being, quality of life and performance, while caring for the planet. Our approach is clearly focused on the future to make the world a better home.”