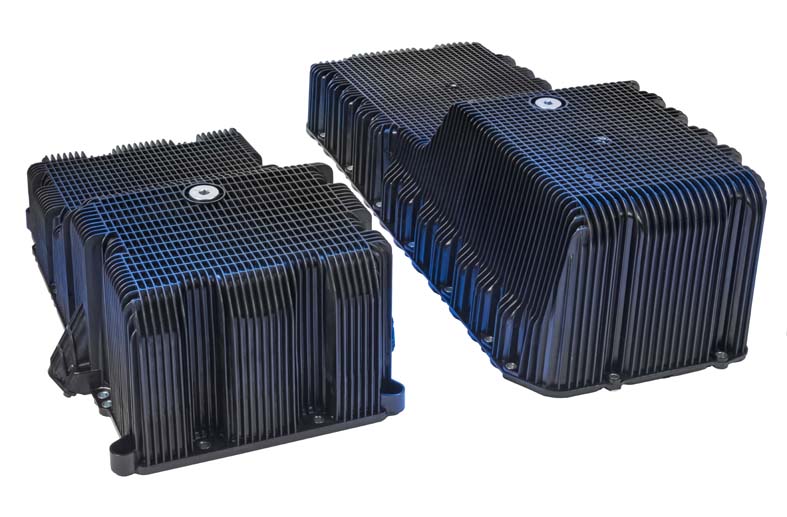

Power management company Eaton has introduced three new plastic oil pans for use on commercial vehicles in the European market. Two of the new plastic oil pans are for medium-duty trucks and one is for buses. Designed in collaboration with diesel engine manufacturer Cummins, the oil pans are now available with the Cummins ISB6.7 engine and will enable commercial vehicle manufacturers to maximise fuel efficiency and meet the newly enacted Euro 6 regulations.

Eaton and Cummins began working on a plastic oil pan for vehicles in the Asia-Pacific region more than five years ago. Recognising the advantages that plastic-based technologies offer vehicles in areas such as weight savings and the growing demand for polymer-based commercial vehicle parts for under-the-hood applications, Eaton and Cummins are once again working in collaboration to develop a solution for the European market.

In order to meet the Euro 6 NOx limits and minimise environmental impact, Cummins added emission reduction technology to its engines while also investigating options for weight reduction. Cummins also wanted to increase oil pan capacity to provide competitive service intervals, which meant the new pan had to be an intricate design to fit in the compact space alongside the engine.

“The new design has complex geometries, and working with plastic allows for greater flexibility with the design compared to metal,” said Andy Easterlow, sales manager – Global Plastics, Eaton. “Working closely with Cummins, our new plastic oil pan significantly increases the oil capacity compared with metal alternatives.”

Oil pans are traditionally made from metals including aluminium and steel, but plastic pans have many benefits. For example, Eaton’s pan is up to 40 percent lighter helping to reduce overall vehicle weight and contributing to improved fuel efficiency.

In addition, plastic has superior damping properties, which enable commercial vehicle manufacturers to comply with noise emission limits and achieve improved noise, vibration, harshness (NVH) characteristics. Eaton’s plastic unit also does not require additional insulation to meet engine noise emission limits specified in the Euro 6 standard.

The plastic pans also reduce oil leakage. Metal pans often experience oil leakage around the seal, but plastic pans reduce oil wastage and deliver improved performance.

“Cummins always looks to use innovative solutions to reduce the weight of our products and improve efficiency,” said Steve Nendick, communications director, Cummins. “Eaton’s plastics expertise has enabled us to do this on our Euro 6 engines without impacting their durability or reliability.”

“We’re delighted to be introducing these new plastic oil pans to the European market,” said Andy. “We work closely with our customers developing new products and supporting them in fulfilling the latest legislation, especially in respect to environmental requirements.”

Eaton is a power management company with 2013 sales of $22.0 billion. Eaton provides energy-efficient solutions that help our customers effectively manage electrical, hydraulic and mechanical power more efficiently, safely and sustainably. Eaton has approximately 103,000 employees and sells products to customers in more than 175 countries. For more information, visit www.eaton.com.