With the Indian automotive industry moving towards cleaner vehicles on account of the implementation of BS-VI emission norms from April 2020, global standards are finally being met. The BS-VI norms are very stringent and are expected to reduce nitrogen oxide (NOx) emissions by up to 70% along with a decrease in hydrocarbon emissions and particulate matter. As a result, OEMs are making several technical changes in diesel vehicles such as SCR provision for fitting diesel particulate filters and Exhaust Gas Recirculation (EGR).

Leveraging its recent acquisition of WABCO, ZF has launched the new WABCO Diesel Exhaust Fluid (DEF) which is essential for the smooth and hassle-free operation of Selective Catalytic Reduction (SCR) after-treatment systems used to meet BS-VI standards.

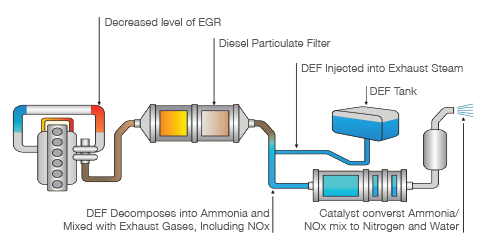

SCR technology uses a catalytic system to break down dangerous NOx emissions produced by diesel engines into nitrogen and water. The chemical reactions used in SCR systems require a constant feed of ammonia gas. In automotive applications, SCR delivers ammonia using a urea solution referred to as Diesel Exhaust Fluid (DEF). This is injected into the diesel exhaust stream and the heat from the exhaust and the fluid along with a catalyst convert the NOx into harmless gases. Diesel exhaust fluid is a 32.5% solution of automotive grade pure urea in de-ionized water.

For the SCR unit to operate effectively, the DEF must meet exceptional standards of purity. This standard, published by the International Organization for Standardization (ISO), defines the required purity level of the diesel exhaust fluid that can be used in SCR-equipped commercial vehicles to meet the emission control norms to protect the environment. DEF is used as a consumable in vehicles fitted with selective catalytic reduction after-treatment devices. A non-compliant solution could damage the SCR system and cause issues in its functioning.

The WABCO Solution

The new WABCO Diesel Exhaust Fluid (DEF) is a high-quality aqueous urea solution that conforms to ISO 22241 for automotive applications. DEF is used in commercial vehicles fitted with selective catalytic reduction after-treatment devices in order to lower NOx concentration in exhaust emissions from diesel engines. DEF is essential for smooth and hassle-free operations of SCR after treatment devices used in diesel engines to meet BS-VI norms. It is produced at the company’s manufacturing locations through a rigorous manufacturing process guided by superior global quality standards to provide customers with a world-class product.

Operational Highlights

The SCR system injects WABCO DEF directly into the exhaust stream. When it enters the catalytic converter, it reacts with NOx from the combusted diesel – producing non-hazardous, naturally occurring nitrogen and water. Due to its high quality standards, the product is very safe to use across all diesel engines with SCR.

Why WABCO DEF?

Some of the most important benefits of using WABCO DEF include:

- It meets 2010 EPA regulations, ISO 22241 and BS-VI standards and can be used for BS-VI-compliant diesel engines as well.

- It protects the SCR system. A robust manufacturing process and rigorous quality standards make WABCO DEF safe for diesel engines with SCR systems.

- It is an environment-friendly solution. WABCO DEF is bio-degradable and does not pollute air, water or soil.

Application Range

WABCO DEF can be used in all diesel engines equipped with SCR technology – including buses, trucks, cars, off-highways well as agricultural and farm technology vehicles.

Availability and Packaging

WABCO DEF is currently available as a standard consumable across all the company’s authorised service centres and distributors. It is currently offered in retail packages ranging from 20 litre buckets and 210 litre barrels to 1,000 litre IBC tanks. Customers are also offered the option of setting up DEF dispensing stations which can be co-located at fleet outlets, service points and fuel stations. The consumption of DEF and refill requirements varies depending on the vehicle, manufacturer, usage pattern and driving style and conditions.