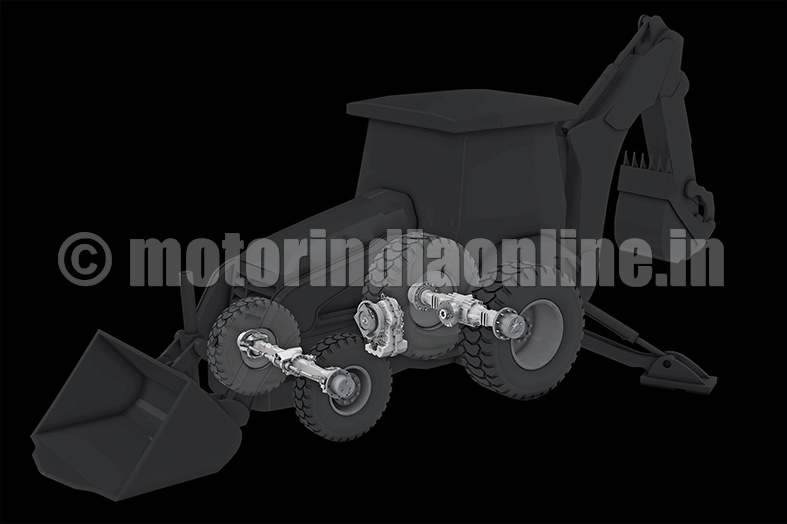

Backhoe loaders are a combination of wheel excavators and wheel loaders: loading at the front, digging at the back, and, in between a power drive, embedded in a manoeuvrable vehicle design. As genuine all-rounders they can also be combined with various hydraulic attachments, for example for drilling, digging, pumping, breaking, compacting or cutting. Consequently, backhoe loaders are seen where most varied work has to be done and special machines would not be economical. In particular a lot is demanded from the front axle. It has to overcome the conflict between high loadability and high steering precision. The universal axle concept facilitates front-wheel and four-wheel steering.

Demand for small, self-propelled off-road vehicles is on the increase. This is particularly true in inner-city areas were modern vehicles must in future be more mobile and manoeuvrable. This trend is also expected to continue with backhoe loaders. ZF offers a system for backhoe loaders consisting of a steerable driven front axle, the compact driven rear axle and a synchronized four-gear or power shift transmission.

WG-90 transmission

The WG-90 series of transmissions offers a high level of efficiency. Through the use of a built-in filter element, ZF has increased the oil change interval to 2,000 operating hours. This reduces the operating costs and increases the availability of the backhoe loader for actual operation. In addition, it preserves the environment.

For both fast reversing and high road speeds the WG 90/94/98 power transmission offers the best credentials. The hydrodynamic powershift transmission is designed for engine output powers of 65 to 90 kW at 2,600 rpm. Maximum turbine torques between 630 and 830 Nm are possible depending on the model. The transmission is primarily characterized by its versatility, because it can be completely adapted to the relevant applications. Additionally, there is the option of switching in the front axle drive on difficult terrain. The ZF transmission also offers a high gearshifting quality and in this respect additionally relieves the driver through noise optimization.

The front axle of a backhoe loader must be rated for heavy loads. It must bear extreme stress peaks during breakout with the bucket and also retain its steering precision with a loaded bucket. ZF has specially developed the driven multisteer axles for these requirements. Even under extreme stresses, the hydrostatic steering system operates reliably, precisely and smoothly.

The steering cylinder is integrated into the axle housing for protection and operates symmetrically, i.e., with an equally large steering angle to the right and left. Combined with a negative scrub radius, this allows high manoeuvrability even with large front wheels. With a maximum output torque of up to 46,000 Nm the huge loading capacity of ZF axles becomes very apparent. This power output is emphasized with a dynamic axle load of up to 10 tons and a static axle load of up to 22 tons. The respective engine power may be between 70 and 80 kW depending on the model.

ZF Multitrac MT-B 3000

The types MT-B 3065/3070 and MT-2085 are available for the classical design of the backhoe loader with a rigid rear axle. The axles are intended for high axle loads and have internal, wet multidisk brakes with high braking torques. The parking brake on the drive flange can be implemented as a disk or multi-disk brake depending on the customer requirements. The differential is available with a hydraulically actuated dog-clutch or multi-disk lock or as a limited slip differential.

Depending on the model, the maximum output torque ranges from 65,000 to 123,000 Nm. The robustness of the axles becomes apparent with the static and dynamic axle loads: from 9.5 up to 13 tons. In addition, the ZF Multitrac axles are characterized by their service-friendliness and high service life.