The construction industry is undergoing a significant evolution, resulting in the need for high degrees of flexibility and rapid development cycles. ZF is poised to address those challenges at EXCON India in Bengaluru where the company (Hall 1, Booth F121) will demonstrate how it’s expertise in driveline technology and intelligent system solutions make them the ideal partner to meet these demands. ZF’s technologies contribute to low or zero emissions and offer increased productivity at construction sites.

Electric Drive Solutions – Zero Emissions Technologies Deliver Maximum Performance for Construction Applications

ZF’s newly developed eTRAC electric drive system combines the performance and productivity found in traditional drivelines with important benefits that electric systems can offer. Thanks to its modular design, this new range of electric drives can easily be adapted for construction applications, providing:

- Zero emissions without compromising performance

- Low noise level

- Efficient electrical components

- Robust and reliable mechanical driveline

- Compact installation space

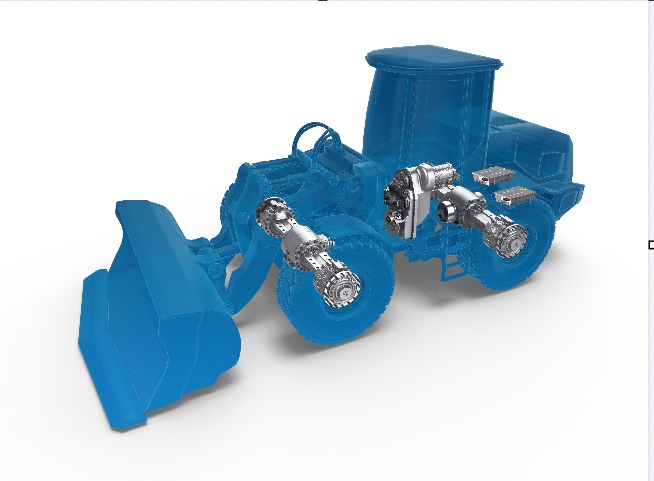

Compact vehicles such as loaders, site dumpers or telehandlers are the early adopters of e-mobility solutions for the construction equipment market, particularly in urban or emission-regulated areas. The eTRAC driveline system – with its range from 20-60 kW continuous power and for 48/96/650-volt emotors (Fig.1_electric compact loader) – provides the necessary zeroemission drive required for these vehicles. ZF is a full system supplier, providing both the electric drive as well as a combination of front and rear axles, inverters and an eDCU (Electric Drive Control Unit). This best-in-class solution achieves the same output as conventional drivetrains, without compromising traction and end speed performance.

ZF’s newly launched eCD (electric Central Drive) system for backhoe loaders consists of a two-speed powershift transmission with integrated parking brake, electric motor, and inverter. To meet increasing customer demand, ZF also offers the ePTO to operate the working hydraulics.

The system can also be optionally adjusted with an axle disconnection. The system can be scaled up to peak torque 850 Nm and continuous power of 80 kW. Three power classes of ZF’s electric central drive system – eCD50, eCD70 and eCD90 (Fig.2_electric backhoe loader) – are available to cover different vehicle sizes for targeted applications. The electric central drives can easily be adapted for various vehicle applications including mobile excavators, telehandlers, or forestry equipment.

To complete the range of electric drives for larger construction vehicles, ZF is offering the eTRAC eCD110-210 series for mid-sized wheel loaders, consisting of an electro-mechanical powershift transmission as well as one emotor for traction and ePTO. An electric drive control unit for overall system performance and power management completes the system. With a 650 V operating voltage, the system can be scaled up to 120 kW continuous power while the ePTO ranges from 30 to 70 kW continuous power (Fig.3_electric midsized wheel loader). Thanks to its modular design, the system can be integrated into additional vehicle applications and can be driven independently from the power source. The company´s solutions can be adapted for both battery-electric vehicles and fuel-cell battery electric vehicles, which will also play a significant role in the future of construction equipment.

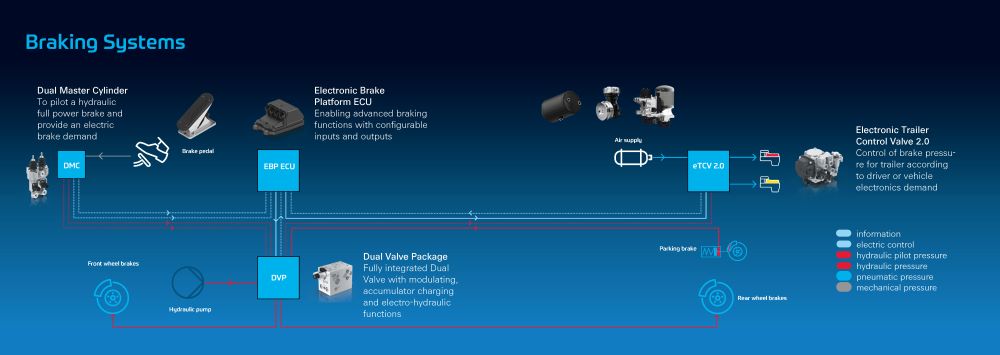

Intelligent braking portfolio provides turnkey solutions for off-highway customers

- ZF’s electrohydraulic braking solution supports rapid transition to electric and autonomous vehicle applications

- Scalable technology offers ease of installation, adaptable brake pressure

A global leader in hydraulic and electrohydraulic braking systems, ZF supports customers in the heavy duty, off-highway, construction, mining, and agriculture sectors with safe and efficient brake technology.

The company’s newest brake-by-wire solution (Fig.4_ZF brake-by-wire system) is an important step change, as it provides vehicle manufacturers the ability to control deceleration via an electronic signal that adjusts brake pressure when needed, removing the need for hydraulic lines in the cab and evolving towards remote and autonomous operation.

The system is comprised of three components: an electronic pedal, electrohydraulic brake valve and a universal controller. Together, the system offers vehicle manufacturers ease of installation, electrohydraulic brake valves for precision brake control and adaptable pedal response/brake feel that can be customized to fit a vehicle’s brand identity. It also provides key operator benefits including reduced cabin noise, and passenger car-like comfort for brake feel.

The Future of Logistics: Intelligent and innovative System solutions from ZF

Increasing just-in-time production, the rising number of online orders as well as longer and longer routes of transport are only some of the actual drivers in the logistics industry. Therefore, not only fast but also efficient and safe goods transport becomes more and more important. Another aspect to be mentioned is the reduction of danger potential for employees.

In doing so ZF provides intelligent mechanical systems for IC forklifts and electric forklifts and underlines once more its capability as technological leader with system competence.

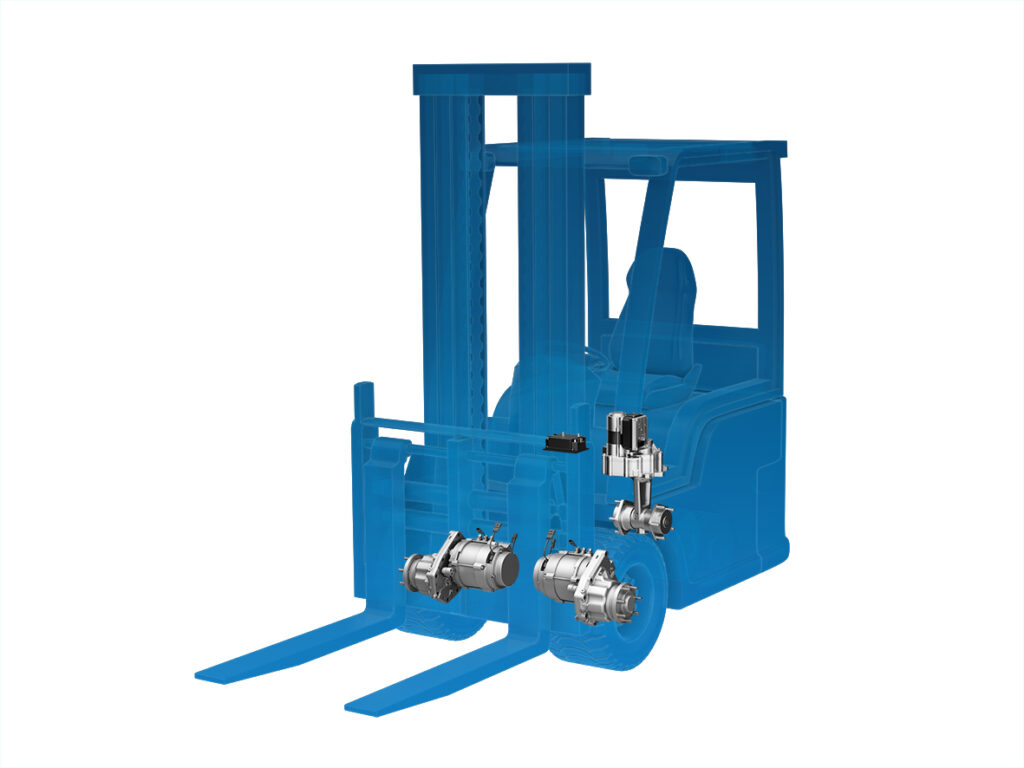

ZF develops intelligent mechanical systems for electric forklifts Whether zero-emission and quietly operating electric forklifts for usage in buildings or diesel forklifts who must transport high loads for a long distance outside. The technology therefore comes from ZF. For both applications ZF offers a large product range.

Thus, ZF offers tailored and efficient driveline solutions for all vehicle categories and technology levels and provides with its “Best Choice” strategy the best solution accordingly of the respective customer and market requirements.

As this year’s Excon India ZF introduces an innovation from the well-known eTRAC series for electric forklifts. The model range of the dual-motor front wheel drive eTRAC GP25 was extended by a Heavy-Duty version

(Fig.5_electric forklift). Besides the advantages concerning energy efficiency, noise and maintenance intervals which distinguishes the eTRAC GP range in general, ZF offers with its Heavy-Duty version solutions for even larger forklifts. In comparison to classic eTRAC GP25 which is designed for a max. wheel load by 2 tons or tire size of 18 inches, eTRAC GP27 (Fig.6_ZF eTRAC GP27) can be applied in forklifts with max. 2.5 tons wheel load or tire size of 21 inches. This is enabled by even more solid wheel bearings as well as a reinforced housing.

ZF Group announces plans to extend local production of transmissions and axles in Coimbatore

The ZF Group has indicated that it is well poised and stays positive on the significant evolution within the construction industry in India. The industry is witnessing an increasing need for intelligent system solutions, sustainable technologies, and a rapid development cycles to support customer expectations, and ZF Group is ready to meet these expectations.

The company demonstrates its expertise in driveline technology and intelligent system solutions making it the ideal partner to meet customer expectations at the EXCON India 2023, (South Hall 1, Booth F121). This showcase of global technologies and investment in a new plant reiterates the Group’s commitment to the growth of domestic industry in the region and its focus on the region.

ZF Group, a global leader in hydraulic and electrohydraulic braking systems, supports customers in the heavy duty, off-highway, construction, mining, and agriculture sectors with safe and efficient brake technology. ZF’s technologies contribute to low or zero emissions and offer increased productivity at construction sites.

The Indian Off-Highway segment is estimated to grow significantly. In India, the construction industry is upbeat about the market potential with rapid urbanization and the push for infrastructural connectivity, which the country is witnessing.

The industrialization of the ERGOPOWER M transmission series at ZF Coimbatore plant will contribute to that development.

In line with these plans, ZF has made investments in a new plant of over 12,000 sq mts to cater to the domestic and export market. This will help the plant to cater its production to domestic and export requirements. The new plant in Coimbatore together with the main hub in Germany will support the production capacity needed for the future market growth in the global construction equipment market.

Akash Passey, President ZF Group in India said, “This new plant and localization of transmissions and axles at our plant in Coimbatore will further our ambition of ‘Make in India for the World’ and ‘Make in India for India.’ This move makes us more agile in meeting customer expectations and enables our customers to get easy access to our world-leading technologies with local manufacturing competencies. The economic tailwinds of growing urbanization and the key thrust on infrastructural growth, makes the ZF Group in India is positive about the market and the opportunities present.”