Wrong pressure in the tires of a commercial vehicle is an industry-wide problem. Trailer tires typically have the worst air pressure. Low tire pressure can lead to tire damage and accidents. Fleets face the tire under-inflation problem because it takes too long to check pressure in all tires. It is also difficult to reach the inside dual in twin tire. Inflation gauges used are inaccurate, and drivers lose the valve cap after pressure check.

A truck tire loses around 1 to 3 PSI/Month (.07 to .21 Bar) depending on the tire materials and construction due to osmosis through the tire casing. Slow leaking punctures in the tread area can cause a tire to lose several PSI per day or more leading to serious under-inflation issues in a short period.

These days, more and more fleets are using telematics to observe real time tire pressure and maintain it at optimum range for maximum fuel mileage and increased tire life. York Tire inflation System from PSI, removes this necessity by automatically filling the air in the tire whenever pressure falls below the optimum value. It also ensures the safety of the driver and the truck.

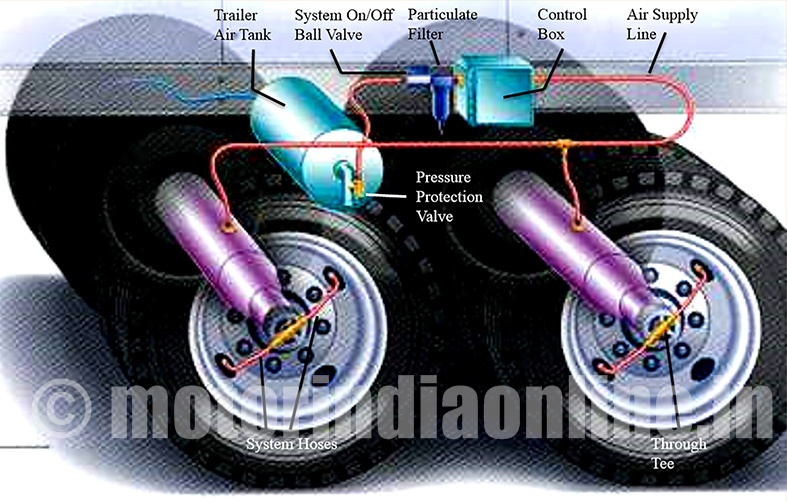

York Tire Inflation System from PSI is easy to install, lower in cost and easier to monitor. It works smoothly. Air from the trailer air supply is routed to a central control box and then into each axle. The axles act as conduits to carry air through a rotary union assembly, which distributes air to each tire as needed. However, periodic inspection is required.

The system consists of a control box with adjustable pressure regulator and a flow switch, rotary unions, stator, custom-made hoses and warning light. Air is added automatically whenever the tire drops below the control box pressure setting. When air is being added to a low tire, the PSI warning light is illuminated, which the driver sees in his side mirror. This means the system is working and doing its job of adding air to one or more low tires. However, the driver should inform maintenance that the light was illuminated while driving down the highway and the affected tires should be repaired.

The system does not require any electrical power to monitor or automatically inflate tires with low pressures. Also, every tire is independent of each other. The rotary union is designed with one-way check valves. If one tire is low, it will not affect any other tire. Air is only added to the low tire.

Alok Sharman, CEO of York Group of companies, said that York is partnering with global players who have the best available technology for truck trailer transportation. York partnership with PSI will give customers reduced maintenance costs and far fewer failures on the road. York products are known for their performance in challenging operating conditions such as poor roads, overloading and dusty environment.

A fleet will save one or more tires from being completely destroyed by specifying York Tire Inflation System from PSI. When a fleet buys trailer with this system, the regulator in the control box is set to the fleet’s specified tire pressure. However, the regulator is adjustable and can be recalibrated.