York Transport Equipment India (P) Ltd., part of SAF-Holland Group, is considered one of the leading suppliers of trailer axle and suspension systems in India. Rajesh Rajgor had the opportunity to interact with two senior company officials to know about the latest developments within the company and whether the recent downturn has had any impact

York Transport Equipment India (P) Ltd. (York), part of SAF-Holland Group, is considered one of the leading suppliers of trailer axle and suspension systems in India. The company distributes a full range of truck and trailer components in India as well as the APAC region. York manufactures most of its products in India and also produces some special axles for export to countries like Australia, Singapore, South Africa and Indonesia.

In this interview, G.S. Chatterjee, Managing Director, and Gurmukh Singh, Senior General Manager – Sales and Service, discuss the impact of the increased axle load norms, the current market conditions, new product offerings, bolstering engineering, research and development, and services.

Excerpts:

Could you elaborate about the impact of axle load norms?

GC: The increase in load capacity due to the new axle load norms has led to an underutilisation of fleet as the operators now need fewer trucks to carry the same amount of load they were carrying earlier. Hence, we now have operators who are not willing to add to their fleets till their load requirement increases. However, despite the market scenario, we have done reasonably well as the trailer axles from York provide substantial load benefits and advantages to our customers. If you look at the market share for York in India in the trailer segment, it is around 50% today, which is a heartening in the current downturn.

GS: There are around 1,200 to 1,500 prime movers that get sold every month now. Among them, around 200 to 300 trailers are fitted with old axles or are coupled with old trailers. Therefore, the market size for trailers is close to 1,000 to 1,200 trailers. If we calculate even 2.5 axles per trailer, the market requirement is of 2,800 to 3,000 axles every month and we are selling around 1,700 units per month currently. It is therefore clear that customers understand our products which provide optimum value to them.

How about the sales and service segment?

GC: Customers trust us because we have been in the industry for so long, always providing quality services and products as compared to our competitors. We are known not only for our products but our timely deliveries too. We have slotted customers as per the volume into platinum, gold and silver categories to take care of uptime. While a customer with large volume in the platinum category will get delivery the same day, the delivery for gold and silver customers would be within 24 hours and 48 hours respectively. We also get strength from our engineering and research and development facilities from Germany as well as in India. The Indian engineering know-how helps us to roll out products as per the Indian road conditions and client requirements rather than merely importing from elsewhere.

GS: We have improved our sales and service network and expanded it to over 350 centres across India. We also conduct free services campaigns, maintenance trainings and repair wherever required with the help of our service network and our own 50 service engineers deputed across India. We have observed that customers are very loyal to us due to the simple reason that they won’t face any problem with our products, within the warranty or after the warranty period. In case a customer faces any problem in York’s aggregates, we are ready to provide immediate service and get his trailer on road within 24 hours anywhere in India.

What does your move towards air suspension imply?

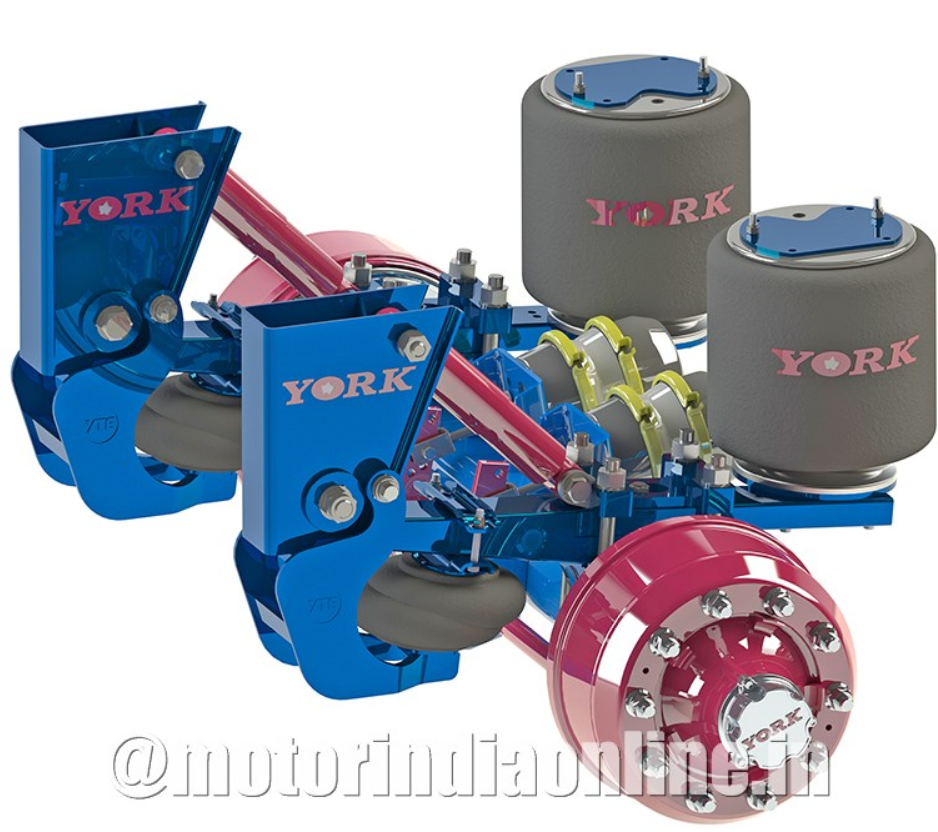

GC: Innovation and bringing out customer-centric products is key to our growth. After the success of Tecair 1 air suspension, disc brake axles in the export market, and steerable axles and mechanical axle lifts, we have launched Tecair 1 HD (heavy duty) air suspension for heavy duty applications with heavy duty hangers and brackets. Recently we launched HD 15 T axle for off-road and overload applications. We are also in the process of launching a range of axles and suspensions in 2020 which have been developed to reduce maintenance and improve performance in Indian conditions. We are offering solutions for a wide range of applications that include container trailer, cargo and fridge van, car equipment carrier, liquid and bulk tank trailer, mining trailer, heavy machinery trailer, port trailer, dump trailer and logging trailer. We are known for offering complete quality trailer products like axles, mechanical suspensions, air suspensions, couplers, landing gear and other accessories required by trailer manufacturers.

GS: Most of the trailer builders are shifting towards using air suspension due to various factors like proper weight distribution, improved stability, and optimum brake performance. Also, customers get the benefit of 3 tonnes of extra payload, given the fact that each axle will now be able to carry a tonne of extra weight. The new regulation allows for one tonne extra per axle if the trailer is fitted with air suspension. These automated air suspensions work as a boon to many transporters who run empty on return loads. When running empty, the two axles can be lifted automatically which improves the fuel efficiency, tyre wear, tear and braking. Although the initial cost of acquisition is higher than the mechanical suspension, the operator can recover the cost within 9 to 13 months. We are closely working with fleet operators and demonstrating to them the viability of our product range.