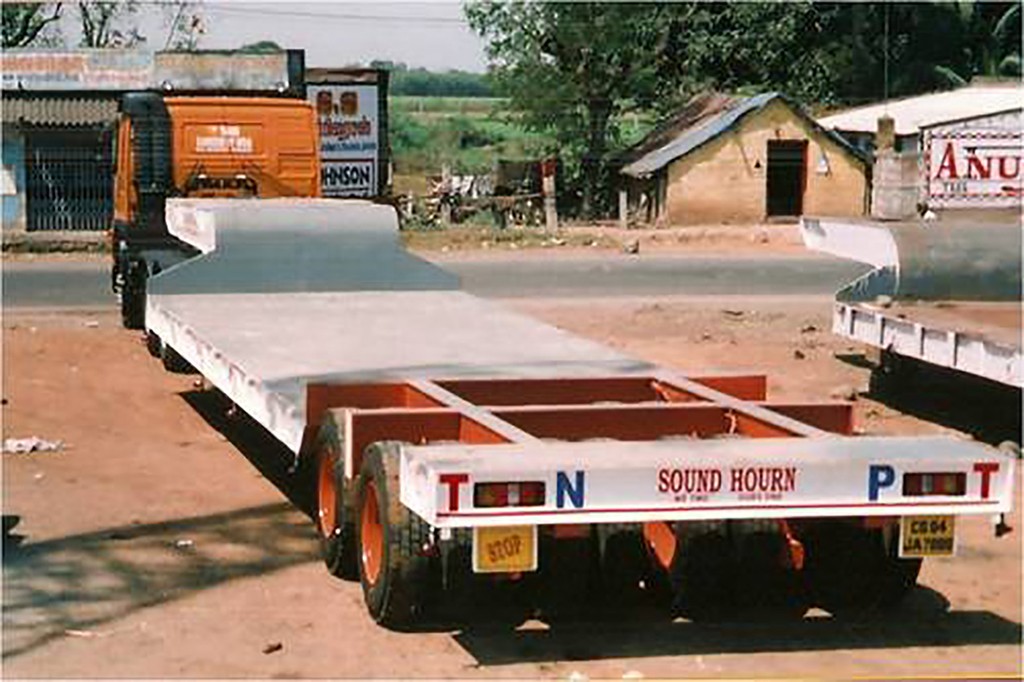

Earlier, the trailer industry was majorly owned by players in the unorganised sector and the ratio was almost 70% unorganised and 30% organised manufacturers. Gradually, trailer manufacturing in India moved from the unorganised to the organised sector. Today, big Indian players in the trailer market have taken this opportunity with regards to growth to produce safe and reliable trailers. It must be mentioned here that the Ministry of Road and Transport and Highways has come out with a notification to bring about amendments in Rule 93 relating to the dimensions of motor vehicles under CMVR Rules 1989. Also, the implementation of Trailer Code AIS 113 uniformly across the country could prove a gamechanger in making the sector more organised and professional.

These amendments would provide standardisation in the dimensions of the motor vehicle which would be in line with international standards and a step towards improving logistics efficiency. The initiative by the ministry on the truck body code is important in order to eliminate the arbitrariness of the RTI and the transport operators, which otherwise results in unsafe vehicles. This will help in meeting the stakeholders’ interest. The topmost priority in laying down the norms is to propose vehicle stability criteria, roll over stability, lateral stability, turning radius, type approval and confirmation of product and its procedure for each model variant.

Need for Professionalism

This implementation will need a professional approach not only by the body or trailer manufacturers – which is currently absent if we consider the local market fabricators – but will also require trained manpower and specialised teams to cater to it. Unfortunately, these practices are not followed in the current market: people are engaged in customised designing using used axles and suspensions which is a violation of the norms, thus making it unsafe for vehicles to ply on the roads – unsafe both for the drivers and the commuters. Safety components such as horns, mirrors, lighting, signalling devices, seats, SUPD (side under-ride protection device), RUPD (rear under-ride protection device), reflective tapes, etc. are notified under specific rules of CMVR.

Although the government tries to enforce safety of trailers, over the past few years local players have not been following safety measures. For instance, low quality RUPD and SUPD are used as cut pieces by local fabricators – a matter of serious concern. As per RTO norms, in 5525 4 x 2 (six-wheeler), prime mover air suspension is strictly mandatory but in local areas where customer influence is strong over government authorities, unorganised players are taking advantage and using standard models with mechanical suspension, which is registered although trailer code is required for all.

This is not only a violation of the CMVR norms but also makes it unsafe for the vehicles to ply on the road. Transporters are getting their vehicles passed unethically without air suspension fitment for getting higher load-carrying capacity just to increase profitability. As per the new increased axle load policy, a trailer with air suspension will get one tonne extra payload per axle. But in doing so, commercial vehicles and trailers are being overloaded without following the guidelines laid down by the transport ministry, indirectly damaging the highways, which are a national property. However, on the optimistic side, things are changing and customers, after having seen trailers supplied by big companies, have started to appreciate the technical content and are increasingly moving away from the unorganised sector.

Along with this, people are also evading taxes by various methods. The material and labour charges are accounted separately to move out of the tax net and there are inadequate norms or standards for the component inputs. Price is the great strength of local fabricators to attract customers, a totally unethical or unhealthy practice. It is also seen that unorganised players are not providing full ABS and are not complying with the norms laid down by the Automotive Research Association of India (ARAI). As per the norms, the maximum width of over-dimensional trailer is 2.6 metres but local players continue to evade the rules. In many cases, unorganised players get a one-time registration on the basis of invalid documents without revealing the correct application of the trailers. The Indian truck cabin industry has been eagerly waiting the cabin codes since the truck driver’s safety and comfort is a major issue.

While the truck driver’s cabin will have to meet certain standards like adequate seating space and controlled cabin temperatures, compliance to crash tests, mounting instructions and safety norms will see a total change in the outlook of the cabin industry which is also linked to the future of micro and small-scale industries in the country. The new Motor Vehicle Act is expected to permit movement of only those vehicles with mandated cabins which will push the OEMs to sell vehicles fitted with a proper cabin. Once the bus body code is implemented, the government plans to implement the AIS 93 (Automotive Indian Standards) code, ensuring code of practice for the construction and approval of truck cabs and truck bodies.

Need for Change

One of the main concerns envisaged would be the resources required for accrediting the body builders and approving and validating the products. Moreover, in the western part of country it has become a recurring practice of a few small trailer manufacturers when it comes to overload application which is used outside the remote coastal region, surpassing government norms for major port applications, namely, coal or clinker. Among other things, the truck-trailer sector is vulnerable to a wide range of unethical practices, especially in the finance sector. These include over-funding with financial organisations not demanding proper invoices from local manufacturers. Further, local fabricators are making trailers without taking into consideration the required norms and valid certifications and vehicles have been approved to run on the road.