E-mobility, electromobility and electric vehicles are buzz words that we hear regularly. Over the past few years, this technology has gathered significant momentum and it shows no sign of slowing down. eMobility is not just about cars. It also applies to e-Bikes, e-Skateboards, e-Scooters and even electric passenger aircraft and helicopters.

The eMobility market is very fast paced with new technology and players constantly emerging. It is one in which Original Equipment Manufacturers (OEMs) and system suppliers are faced with distinctive challenges and requirements that are ever changing. This makes the industry unique, in that customers do not yet have clearly defined standards or established solutions. The innovation rate in the industry is therefore extremely high, with strong pressure to bring the right products to market quickly.

Demanding requirements and innovative solutions

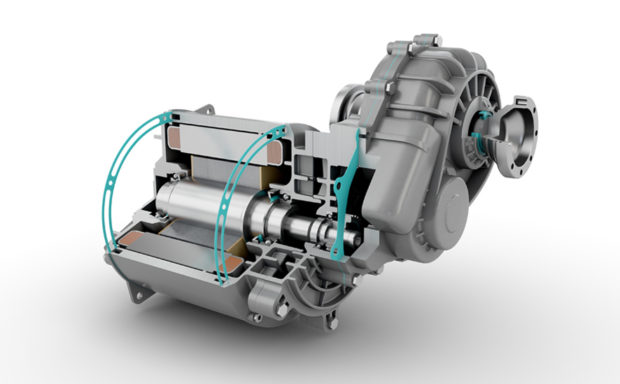

The challenges for sealing are similar in every type of eMobility application. The battery needs to be protected from environmental influences and vibration and other components must operate at high speeds. Additionally, seals must prevent the ingress of dirt and other media, and if the systems are lubricated, they must also be compatible with the lubricant. When it comes to cars, the requirements for seal performance in an electric motor are generally higher than for seals in a combustion engine. E-Motors operate at significantly greater speeds and temperatures.

They also need components to have a high level of media compatibility and ones that can stand up to difficult environmental influences. And, it goes without saying, quality is paramount. Working with major customers in the industry, Trelleborg Sealing Solutions has developed solutions specifically for eMobility applications. These range from specialist rotary seals, advanced compounds and components for the e-Motor battery. HiSpin® PDR RT and HiSpin® HS40, are two products, designed with e-Axle technology in mind. The rotary seals are engineered to effectively run at the high speeds required to maximize the range, or distance a vehicle with electric drive units can travel. By doing this, they will be fundamental in supporting the mass adoption of electric vehicles.

Charging on

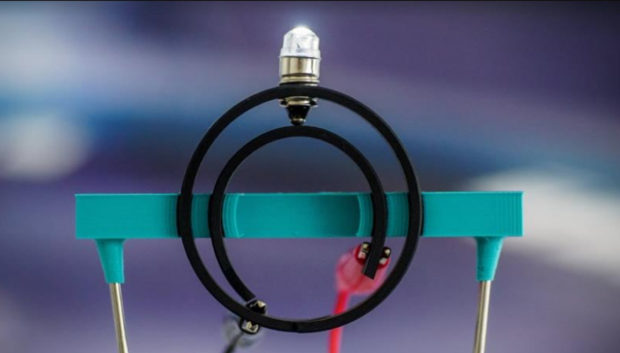

Turcon® MC1 and Turcon® MC2 are the first electrically conductive Polytetrafluoroethylene (PTFE) based compounds for use in spring-loaded and elastomer-energized seals. They enable us to guarantee important properties such as insulation, thermal and electrical conductivity, as well as electromagnetic shielding. These Turcon® materials are an optimum solution for electrical systems, meeting the new and unique sealing challenges it poses. The compounds need to withstand the high temperatures typically found in the e-Motor, as well as the battery’s fluids.

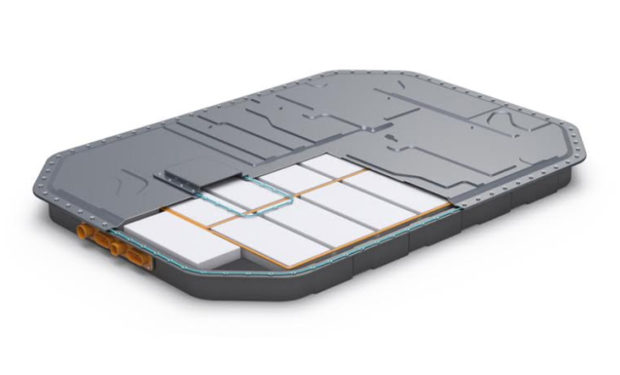

Fluid compatibility is particularly complex as the media used in the e-Motor differs from that used in gasoline and diesel engines, which have established and proven sealing solutions. In addition, there is a further challenge: the chemical cocktail of a fully charged battery is different than that of an empty one. For the battery, Trelleborg Sealing Solutions has developed customer specific battery cover seals. The battery is adapted to the shape of the vehicle, so each battery housing and its sealing solution is always tailor-made. Produced in Ethylene Propylene Diene Rubber (EPDM) with metal bushings, the covers not only protect the battery from moisture but also provide resistance to high-pressure water. If desired, they can provide additional functional features, such as venting, fire protection or damping.

Next steps

Constant innovation is going to be critical in producing e-Mobility solutions that allow electric vehicles to operate effectively and give drivers the independence they are used to from traditionally fueled vehicles. Overcoming ‘range anxiety’ is critical to mass adoption of electric vehicles and supporting customers in achieving this is our focus. We will continue to push for the next innovation that will allow electric vehicles to go further, higher and faster more effectively.