The ULTIMAAX suspension that Tata Motors has launched in its heavy-duty tipper is a result of the untiring hard work of the teams from Tata Motors and Tata AutoComp Hendrickson Suspensions (THSL) for more than three and a half years to thoroughly validate and get the product market-ready.

Says Mr. J.V. Narasimha Rao, Senior General Manager – Business Development, THSL: “The ULTIMAAX suspension is a highly successful product in the US and China, but when it came to adapting it to the Indian operating and usage conditions, we found the erstwhile successful HUV project could not be adapted immediately to our market which is why we have heavily customized it to suit typical Indian usage conditions. We have enhanced the suspension’s load carrying capacity from 27-ton to 37-ton despite having to work within the available envelop space given by the OEM – under the chassis frame and above the ground – and still get an enhanced load rating of 37-ton continuous. This was a real challenge which we managed to overcome by working on both the engineering design and the material capability.”

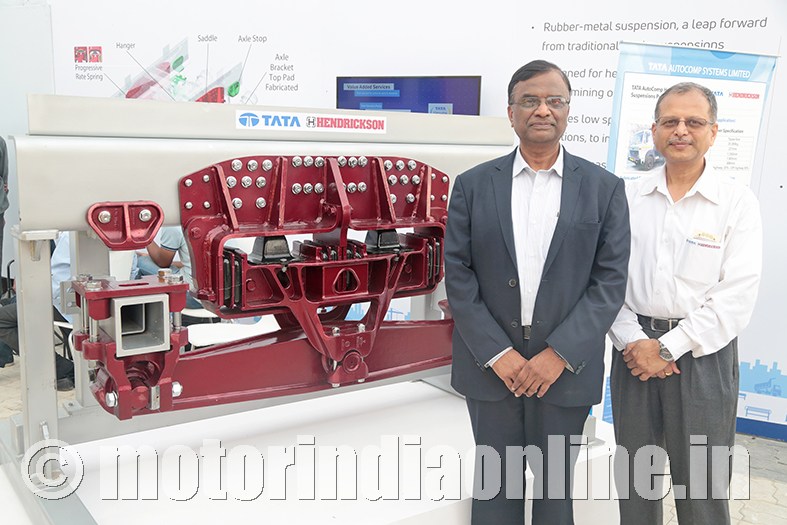

The ULTIMAAX Rear Suspension consists of a heavy-duty beam with central pivot and combination of shear springs and progressive springs, which are the main load carrying components and are made of special proprietary rubber material. Progressive main springs carry greater portion of the load in the vehicle. Its stiffness increases as the load increases without causing an abrupt change in ride characteristics, thereby providing a unique balance of empty ride quality and loaded stability. The use of rubber bushes in the front and rear eliminates the need for periodic lubrication, thereby ensuring total peace of mind for the customer, without the need for periodic visits to the workshop or for using expensive chassis greasing system. The unique design provides long service life and easy replacement of rubber springs to reduce down time.

The ULTIMAAX suspension has been configured for heavy-duty mining applications, for both 6×4 and 8×4 tippers. The product has been put under extensive field trials by both Tata Motors and THSL in order to ensure the end customers have a trouble-free usage of the product.

“We have done trial runs extensively on our own tipper and also on Tata Motors’ tipper on their test track and as per their duty cycles. We have also taken Tata Motors aggregates to the US and tested them along with the suspension fitted on US trucks in rigorous test tracks in the country. In April 2017, Tata Motors decided to release 10 vehicles into the field and leave it to the operators to use them as they normally use their trucks. Now, in about nine months, some of the vehicles have covered over 3,000 hours without any difficulty. The suspension, along with the front parabolic spring which has also been designed to bear the additional load, is now ready to enter the market. Tata Motors has already launched the product in its PRIMA LX 2523.K vehicle and is now showcasing it in the PRIMA LX 2525.K. In the coming months, the suspension will be available across other vehicle models as well”, explains Mr. Rao.

THSL, buoyed by the exciting new launch, evoked fantastic response at the show with customers eagerly asking them for the revolutionary new suspension. Some fleet customers had also placed on record their interest in retrofitting the suspension in their existing vehicles, reflecting the kind of demand the first-of-its-kind product is having. While THSL was delighted at the response for the product, it also made a request to fleet operators to not make any modifications to the suspension and kindly use it as such in order to obtain the best possible results.