Brand TEXSPIN is synonymous with clutch technology in the Indian automotive industry, having pioneered the release bearing technology for over half a century. TEXSPIN has been in the forefront in making technological improvements and upgradation in the release bearing technology. Starting from the introduction of the angular contact technology for release bearings, followed by the path-breaking introduction of the self-centering technology, the light weight combination technology through advanced stamped bearings and insert moulded thermoplastic sleeve to the latest hydraulic clutches (CSC), the journey for TEXSPIN has been one of continual improvement and innovation in the area of clutch technology over the last 50 years.

In the five decades of its path-breaking technological and innovative work on the release bearing, TEXSPIN has done extensive research and has acquired a deep understanding of the entire clutch technology, may it be release bearing or the clutch as both form an integral part of the operating solution, and for any technological development one cannot be separated from the other. With its vast reservoir of knowledge and technological understanding of clutches, the company decided to forward integrate in this application area and provide the complete clutch solution consisting of the release bearing and the clutch assembly with an aim to offer value and technological improvements in the entire solution to its valued customers.

The TEXSPIN clutch is designed to deliver optimal efficiency. The major casting components are processed by high pressure moulding to ensure superior level of casting quality. The cover assembly design is optimized in such a way that it prevents dust entry and reduces the clutch housing temperature to extend the clutch life. To ensure vehicle specific OE quality and for trouble-free installation, TEXSPIN has set up a comprehensive cent percent online testing facility for the clutches as well as an advanced integrated clutch testing facility at its Reliability Centre to ensure that it offers a product in line with its reputation of being the leading cutch solution provider in the country.

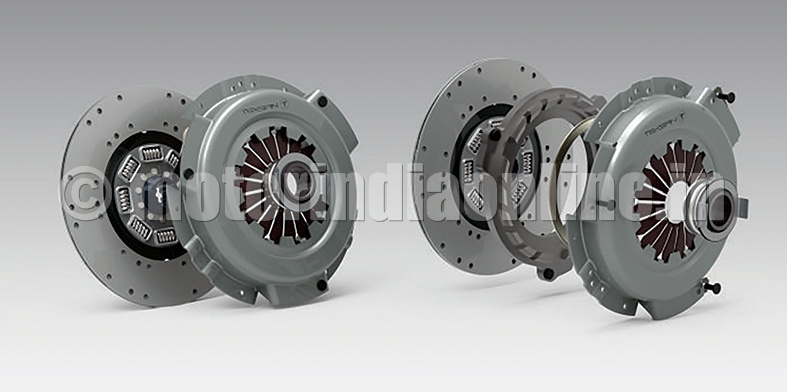

TEXSPIN started working on setting up a clutch manufacturing facility a couple of years back as part its forward integration strategy, and today the new greenfield facility is ready for production of a range of clutch assembly along with clutch parts and kits. It initially started manufacturing clutch assembly in the sizes of 380, 352, 310, 240, 190 and 170 diameter. The range will be further augmented going ahead to serve the entire range of clutch assemblies for which TEXSPIN is the leading manufacturer of release bearings.

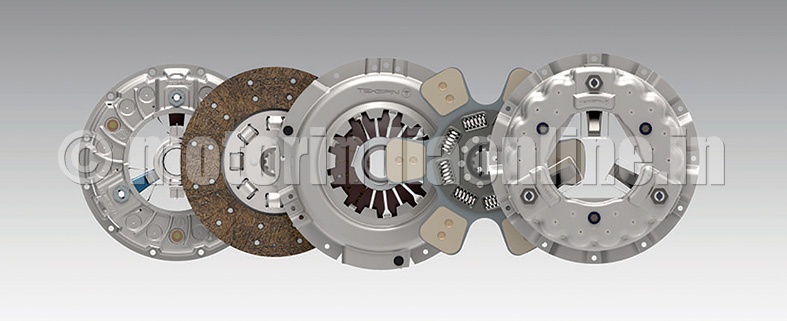

TEXSPIN has set up its facility to manufacture both the coil type and diaphragm type clutch cover assembly. It offers cover design in both deep drawn sheet metal design and in high pressure moulded casting design. The clutch disk is lined with high temperature resistant special facing which has a high friction value which allows the clutch to operate with a lower release load features and offers durability and reliability during operation. Besides, the optimized pressure plate design in combination with the specialized friction material allows for short-term extreme loads and resulting high temperature withstanding capability.

TEXSPIN will manufacture a comprehensive range of specialized Clutch Cover Assembly to service the M&HCV (Coil Type Clutch), S&LCV, PV (Diaphragm Type) and Off Road (Coil type and diaphragm type). The primary objective would be to offer a comprehensive clutch solution to its valued customers leveraging on its vast reservoir of knowledge and technological understanding of clutches gathered over the last half a century.