Over the past so many years, Tata Elxsi has built solution accelerators and targeted applications to address the needs of off-highway and other transportation customers. In this interview with Rajesh Rajgor, Sankar Kumar Rajan Global Head (Rail and FMCE, Transportation Business Unit), elaborates about the company’s products and strategies

Could you elaborate on the role Tata Elxsi is playing in order to make off-highway equipment smarter?

The heavy machinery sector is seeing another surge of technological transition. Internet of Things (IoT), faster connectivity and communications along with advanced artificial intelligence (AI) and analytics algorithms have been the impetus for off-highway heavy machinery vehicles to become smarter and autonomous. Advanced operator and driver assistance systems essentially use a suite of sensors such as cameras, radars which use radio waves and LIDAR which use lasers installed in the vehicle to assist the operator in a variety of scenarios such as terrain visualisation and mapping or avoiding a collision with another object or labour. For more than a decade, Tata Elxsi has been developing the advanced driver assistance system (ADAS) and worked on features such as cabin monitoring, obstacle detection, surround-view systems, and so on. Our experience and innovative solutions in the areas of ADAS, telematics and now electrification would help our off-highway customers to build next-generation solutions and products.

Could you explain to us a few solutions or applications from Tata Elxsi that have improved vehicle and operator safety in off-highway, transportation and other mobility segments?

Over the past so many years we have built solution accelerators and targeted applications to address the needs of off-highway and our other transportation customers. Tata Elxsi’s Intelligent Operator Assistance System (IOAS) may be connected to construction equipment to expedite worksite operations and minimise the number of accidents and fatalities. Through the use of these visualisation capabilities, it is feasible to deploy vision-based 3D terrain mapping technology to assist the operator in making decisions and directing machine operations, such as selecting the work to be completed, monitoring its progress and certifying task completion.

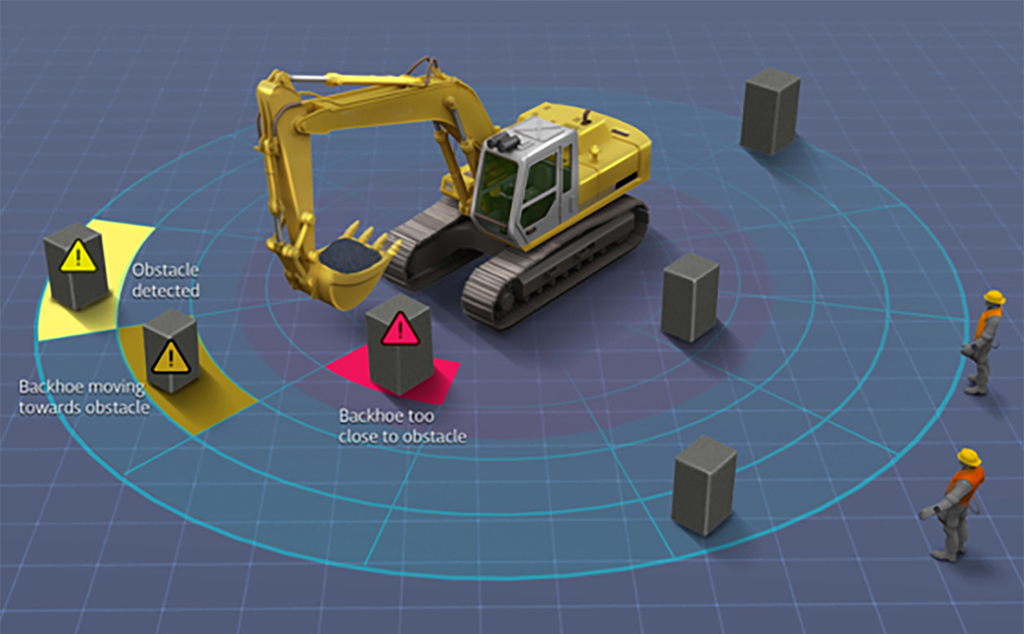

It is possible that this functionality will be improved in the future to allow for remote assignment, monitoring and administration of these activities. On an excavation site, obstacle detection is used to determine whether or not there are any obstructions in the route of the excavator’s arm. It provides an additional layer of security by sensing threats in close proximity to the excavator’s arm and preventing a collision with items in the surrounding area. It provides a signal that warns the operator and assists him or her in making a choice. With technological developments, it will be possible to watch the progress of a project and, as a result, minimise the frequency of site accidents that result in fatal injuries to employees, thereby enhancing site safety.

Additionally, it is critical to maintain the user’s health in the best possible shape in order to maximise the effectiveness of the site’s operations and personal wellbeing. In the automotive sector, solutions like a driver monitoring system help address the growing safety risks caused by distracted and drowsy drivers and also provides the essential assurance that a driver is ready to assume control from an autonomous driving system. More than ADAS being a luxury feature, it is becoming a necessity from a safety perspective, and the amount of safety it introduces is quite substantial. We have solution accelerators and architectural frameworks for data fusion, object detection and recognition, all furthering our capabilities in the ADAS domain. We have computer vision-based solutions for automating rail infrastructure maintenance workflows.

How does data analytics aid in successful equipment maintenance through prognostics, better costs and performance efficiency and what are the trends you see shaping up in transport management?

Data analytics helps understand degradation in the performance of the system or components over time and proactively recommends maintenance well in advance so that the downtime can be minimised with predictive maintenance. This will help reduce the maintenance cost and operational cost for fleet operators. This becomes more relevant when the price of the component and cost of repair in the case of a failure are high. One typical example is predictive maintenance of electric vehicle (EV) battery. Data analytics helps predict the remaining useful life of the battery by tracking the degradation in the system. This helps improve the performance, safety of EV systems and enhances user experience. In a similar way, this can be applied to other systems in heavy machinery which can help reduce vehicle downtime and in turn increase productivity.

How does advanced HIL testing as well as the utilisation of in-house test beds and tools help customers of off-highway construction and farm equipment save time and money?

Tata Elxsi began developing HIL simulations in 2005-06 and used them at its automotive facility. After that, the organisation expanded to component-level HIL rigs, and then system-level simulators. Tata Elxsi also created a multi-system HIL rig which is a comprehensive vehicle simulator for all-electric aspects. The firm also offers an e-mobility HIL, which is a full-featured test automation framework and test facility dedicated to certifying electric vehicles. This simulator incorporates electric motors and can do component level validation as well as modelling of dynamic aspects.

The electric systems of EVs under development may be connected to our e-mobility HIL setup for fast simulation and may be used to evaluate the electrical properties of EV batteries as well as the functioning of the battery management system (BMS) under simulated heat circumstances. The main advantage of HIL testing is that the actual ECU can be placed in the simulation environment and then be simulated as per requirements. The benefit of the components level of HIL testing is that all other interfacing components and signals that come into the ECU can be tested in the simulation environment. In the case of a system, it is typically integrated into the HIL machine and then other systems are simulated. The lack of a few components of the system does not become a deterrent for testing since the HIL machine simulates the properties of the components that are missing in the system.

Therefore, it means that validation can be started even before the entire system is ready, which could provide early results that can be fed into the development cycle and help fix defects early. Tata Elxsi’s system validation and HIL competency teams have extensive experience on different HIL platforms, setting up test infrastructure and test suite development based on product requirements. We assist in setting up HIL rigs, plant model development and maintenance of HIL rigs, development of test frameworks, test cases, test automation and execution of tests in HIL or test rig environments. The capabilities and scale that we have built in this area can be fully leveraged by our customers in off-highway construction and farm equipment segments to deliver high-quality products in quick time to the market.