With timely delivery and growing satisfied customers, Siddheshwar Transport’s stature as a reputed logistics service provider is growing rapidly. In this exclusive article, Rajesh Rajgor highlights the reasons behind the company’s excellent reputation

Pravin Murhe, Director, Siddheshwar Transport started the transport business in 2002 with a Tata Tipper 1613 in the stone crusher transportation and earth mover’s segment. With immediate success and growing work, he ventured into sand transportation in 2007 and then followed up with earth moving work by investing in JCB backhoe loaders. Living in Kuruli, Pune, Murhe had a great knack of developing business in and around the region. He explains: “Although I started my business with the movement of sand, overburdened from the work in stone crushing and earth moving segment I was always inclined to grow the transportation business given the corporates setting up shops in and around Pune. As soon as I got the lead for a proper transportation business, I embarked upon it.”

“In 2011, under the name of Siddheshwar Transport, I started transportation work of wheel rims for Kalyani Maxion,” he adds. Today, Siddheshwar Transport works for reputed clients like Kubota Tractor, New Holland Agri Equipment, Magnetic Marelli, PPG Asian Paint, Meritor Ltd. and Instor India, among others, deploying a total of nine rigid trucks between 9 to 26 tonnes, and around 22 flat-bed trailers. “We carry coils and various other over-dimensional cargo (ODC) from Pune to Mumbai, Bangalore and Chennai for many of our clients. All our vehicles are equipped with technologies like GPS system, fuel monitoring and telematics. We also have manual methods to verify trips and vehicle data every month. The vehicles get monitored from beginning (loading to unloading) to the end. We analyse vehicle performance and driver behaviour on transit in order to conduct timely delivery,” reveals Murhe.

Staying Committed

One of the important aspects of supply chain is the speed of delivery that enables the transporter to provide timely delivery. Constantly expanding consumer demands for same and next day delivery, clear communication of deliverables, schedules of production, etc. has to be done prior to embarking upon a transport journey. In order to smoothly conduct the business and please customers, the company adopted Just-In-Time (JIT) delivery, an inventory management strategy, that helps facilitate speedier order fulfilment with particular applications in raw materials orders as well as manufacturing.

Murhe explains: “For all my customers I am the one who does the business meeting and have requested them to send the schedules a day before the actual transfer. This helps us allocate right vehicle and bifurcate resources. For the greater good of timely delivery all the customers and OEMs have cooperated in this regard and have praised our proactive method on timely delivery.” However, there are times when the schedule was received for a delivery next day, leaving not much time for delegation. One such act of dedication and commitment was displayed by the owner very recently.

Murhe reminisces: “Once we got an urgent order, just a day before the expected delivery, and it so happened that all my drivers were away with their allotted vehicles. I took it upon myself to deliver the material to the client’s factory at night.” Another issue that most transporters face post timely delivery is the time taken to unload the vehicle. “Delivery within a city is easy and faster; it is the long distance travel that comes with delay in unloading at times. In such cases we have no option but to cooperate with suppliers and OEMS. Even though we lose time, the gains in the long term with a satisfied client are much more than the loss,” expresses Murhe.

Vehicle with Quality Axles

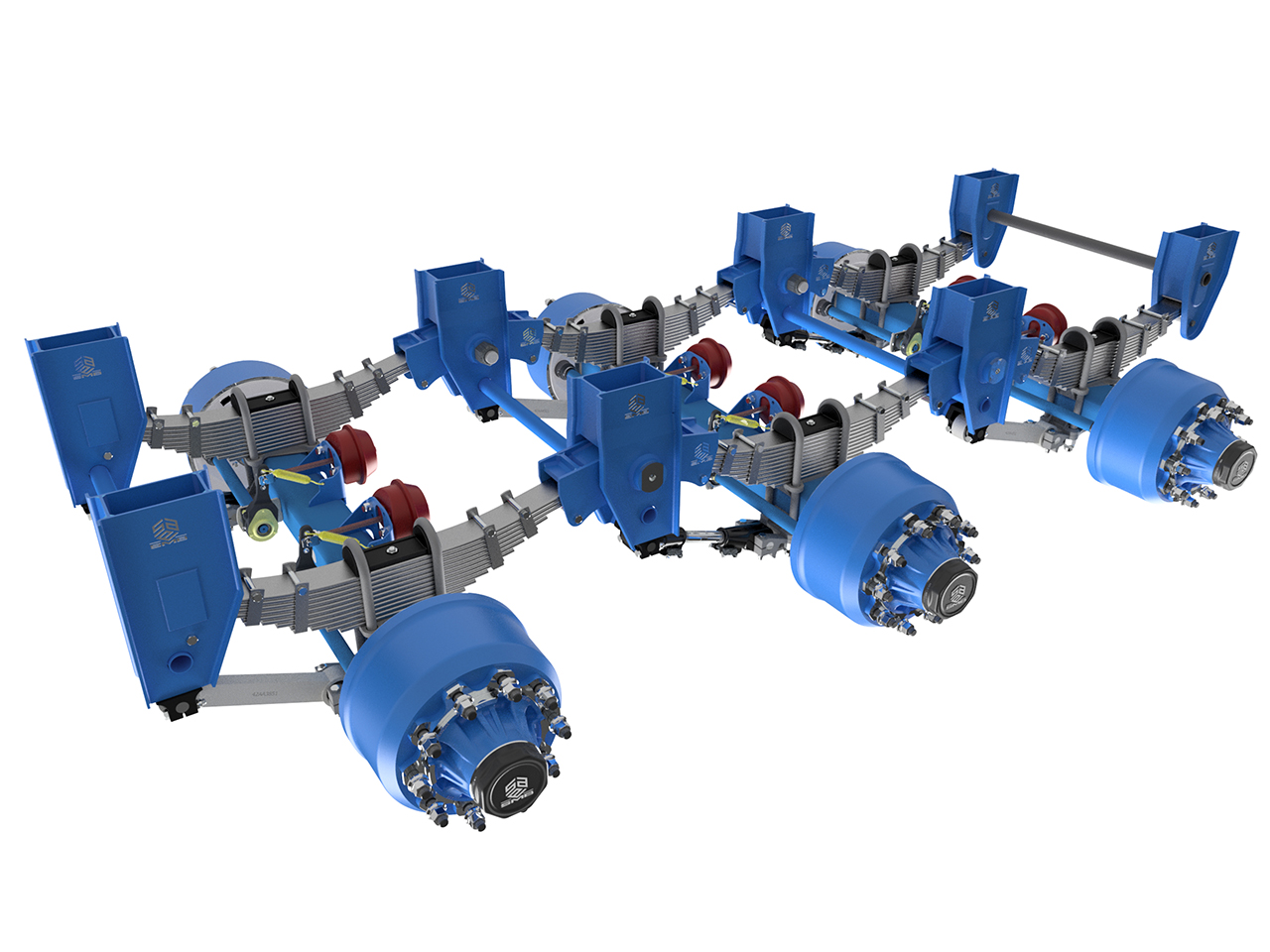

The influence of the cargo weight loaded on the vehicle and the total gross mass of the vehicle on the axles, tyres, braking and characteristics is often ignored. However, Siddheshwar Transport takes special care about selecting right supplier partner as far as load distribution is concerned. The company has partnered with ADR Axles in this regard. Murhe says: “ADR Axles India has supported us a lot from design to execution and deciding the right undercarriage axles and suspension after proper load calculation. They have always supported us with their service network and spares availability across India. Our vehicle’s brake lining life has gone up to 1,50,000 km and leads to a tyre life of more than 1,00,000 km. This would not have been possible without time-to-time preventive maintenance and check-up, especially for brake settings, correct alignments and hub greasing by ADR.”

Additionally, ADR Axles’s service department that conducts the trailers registration is aware about the vehicles in which ADR/SAE-SMB axles and suspensions are used. This helps them make preparations for quarterly check-up for axles and suspensions of a particular vehicle easily. “ADR India provides quarterly free check-up that boosts our vehicle’s performance and ensures that any failures related to axles and suspensions are avoided,” Murhe states.

Vital Cog in the Wheel

Since the transportation business is driven by skilled and trustworthy drivers, Siddheshwar Transport handles drivers in a professional manner. “We select drivers from various interviews and references from the markets and maintain proper documentation about driver’s identity and history of past driving. We also conduct regular driver training for both new and old recruits. In addition to this, we give them yearly bonus, cover them under insurance and take care of their needs,” informs Murhe.

It is this trust in drivers and right choices of vehicles that Siddheshwar Transport is now mulling to venture into third party logistics with proper allocation of inventory and planned schedule delivery. “We are going to buy more rigid trucks with 18 tonnes capacity and some trailers with 52 tonners, for cement transportation use. We are also in talks with car companies to move new cars as a car carrier. Presently, even though we have the wherewithal to handle 100 truckloads of work per month, our growing business will require more wheels on the road,” remarks Murhe.

—

“ADR Axles India has supported us a lot from design to execution and deciding the right undercarriage axles and suspension after proper load calculation. They have always supported us with their service network and spares availability across India. Our vehicle’s brake lining life has gone up to 1,50,000 km and leads to a tyre life of more than 1,00,000 km. This would not have been possible without time-to-time preventive maintenance and check-up, especially for brake settings, correct alignments and hub greasing by ADR.

– Pravin Murhe, Director, Siddheshwar Transport

—

ADR India provides quarterly free check-up that boosts our vehicle’s performance and ensures that any failures related to axles and suspensions are avoided.

– Pravin Murhe