Sentient Labs, a start-up incubated by KPIT Technologies Ltd., is working across the complete value chain that can make mobility green. Rajesh Rajgor, who attended the launch event of a bus powered by hydrogen fuel cell technology, reports how the fuel cell electric vehicles, powered by hydrogen which employs microbes to break down cellulosic biomass into hydrogen and methane with the methane being turned back into hydrogen in a second stage, can be beneficial for commercial vehicles running long haul

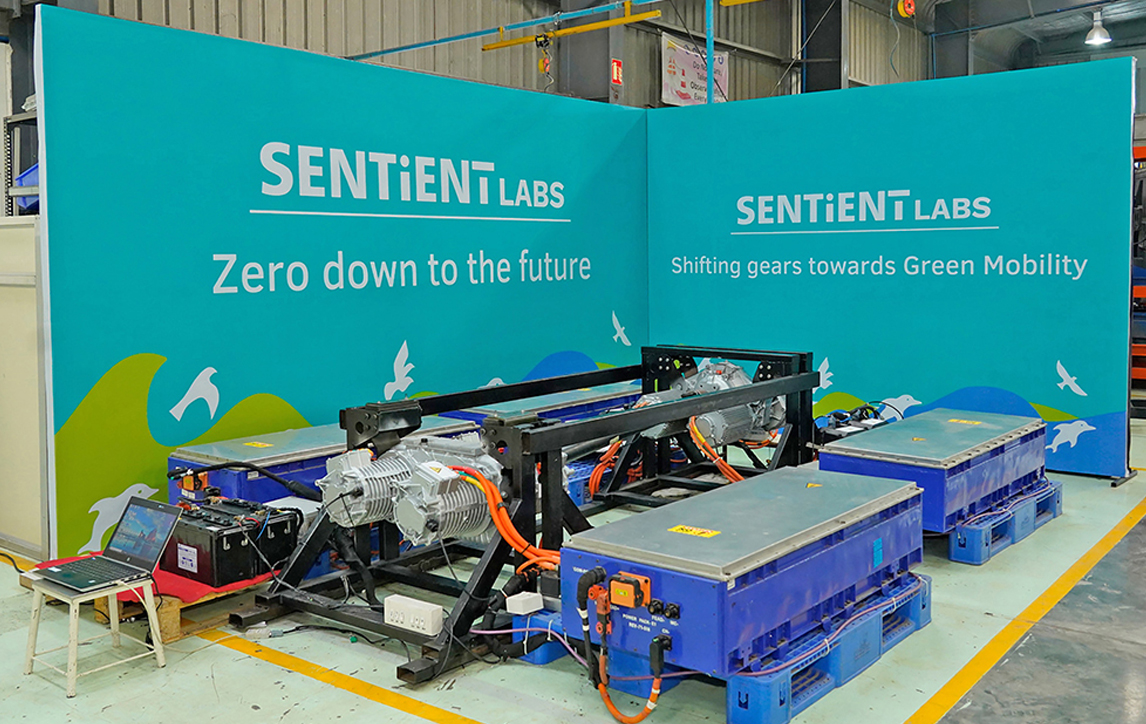

At a specially organised event, Sentient Labs showcased hydrogen fuel cell technology that has been developed in collaboration with the Council of Scientific and Industrial Research (CSIR), National Chemical Laboratory (NCL) and the Central Electrochemical Research Institute. In conjunction with the NCL based in Pune, a government-owned research institution, the company announced the development of fuel cells that can power buses. The intellectual property will remain with Sentient Labs. On the occasion, Ravi Pandit, Chairman, Sentient Labs, stated, “We are pleased to announce the launch of a hydrogen fuel cell power bus that was developed in-house. CSIR-NCL collaborated with a strong technical team on several technology components.”

“This will help power the Hydrogen Mission and the mission to make India self-reliant and, most significantly, sustainable mobility in India. We anticipate widespread adoption of the solution, which will be aided by a number of partnerships. Our efforts will also be critical in allowing vehicle manufacturers and suppliers in India to develop a net-zero carbon route,” he added. The fuel cell utilises hydrogen and air to generate electricity to power the bus. The only effluent from the bus is water, therefore possibly making it the most environmentally friendly mode of transportation. For comparison, a single diesel bus plying on long distance routes typically emits 100 tons of CO2 annually and there are over a million such buses in India.

Understanding the Technology

According to Ravi Pandit, many OEMs are interested in licensing the technique that shall roughly cost USD 400 per kW, which is a third of the cost of a comparable product on the market. He elaborated: “Our highly efficient and cost-effective fuel cell technology is completely indigenous and developed from the ground up. The technology allows silent and vibration-free operation where the output is electrical energy and water vapour. This unique fuel cell stack and balance of plant system is modular and can be developed as required. The solution can be customised and adapted to multiple bus variants i.e. 9 metre, 12 metre and 13.5 metre buses for intercity long-distance application and intracity application.”

When asked about the sources of cost-effectiveness to the fleet operator who work on operational expenses rather than capital expenditure, Pandit stated that Sentient Labs could conduct research and development very efficiently and at a cheap cost. Secondly, a large number of components were created in-house. “This is the first time that any Indian company has built a fuel cell from the scratch with no external assistance. When you build anything from the ground up, you not only learn how to do it but also why. In comparison to other electric buses, the hydrogen fuel cell (HFC) bus features a small battery to support vehicle auxiliaries and provide a limp home feature,” he said.

“Our HFC technology when integrated with our state-of-the-art electric powertrain can deliver world-class solutions to develop multiple kinds of fuel cell electric vehicles (FCEVs). Our goal is to show, test and develop our system so that vehicle manufacturers can use it in mass production,” he explained. This is more efficient than any other hydrogen-producing technique in the country, according to Dr. Ashish Lele, Director, NCL. “The technology employs microbes to break down cellulosic biomass into hydrogen and methane with the methane being turned back into hydrogen in a second stage. This can be beneficial for commercial vehicles running long haul,” he stated.

In a fireside chat between Ravi Pandit and Dr. Ashish Lele, Dr. Raghunath Mashelkar too emphasised: “The technology might make hydrogen available for USD 1 per kg as the scale would simply reinforce the inherent cost advantage of being totally home-grown. Scalability would be possible because of the enormous need. World over, efforts related to green hydrogen revolution are on, but Sentient Labs stands out. At Sentient Labs, challenges that are core to India are understood and solutions are accordingly developed. Digitisation, decentralisation and decarbonisation is what India needs for sustainable mobility and these innovations from Sentient Labs will go a long way.”

Sentient Labs’ vision is to build technology solutions for sustainable mobility with a current emphasis on hydrogen-powered technologies. It has identified bottlenecks in battery technology, fuel cell technologies and technologies for hydrogen generation. It had announced the world’s first technology that generates hydrogen directly from agricultural residue for use in fuel cell-powered vehicles. This technology adds to the line-up of efforts around sustainable mobility. Pandit responded to a question by saying that Sentient Labs was working on various hydrogen-producing methods such as electrolysis and pyrolysis.

Greener Self-Reliant Solutions

In addition to the hydrogen fuel cell technology, Sentient Labs has also indigenously designed and developed from ground up other key components like balance of plant, powertrain and battery pack. All of these components have been deployed on a 9 metre, 32-seater, air-conditioned bus. This is designed to provide a range of 450 km while utilising 30 kg of hydrogen. A modular architecture allows for changes in the design to suit requirements of range and operating conditions. Putting both the technologies by Sentient Labs together can be an environment-friendly and economically attractive proposal.

While hydrogen generation technology can provide an alternative source of revenue to farmers, replacing diesel buses with hydrogen fuel cell buses will improve air quality drastically and also reduce oil import costs. Sentient Labs is passionate to support India’s sustainable development goals (SDGs) for transportation by providing clean and smart technologies. Additionally, the company is working on new technology for energy storage that does not depend on imported raw materials. “We believe that we will be able to bring this to the market in the next few months. Our electric sustainable technologies are 100% made in India, built from the ground up, and supported with indigenously built manufacturing capabilities,” informed Pandit.

“This marks a great step towards a self-reliant and self-dependent India,” he added. On questioning if fuel cells and hydrogen are safe, Pandit shared: “There are extensive safety standards for storage, transport and handling of hydrogen. World over, fuel cell technology is already deployed in various applications of public transportation and have clocked a million miles. They have gone through thousands of hours of extensive testing. The current technology and safety standards ensure that the vehicles are safe and therefore it is eminently justified for public transport.” Sentient Labs’ fuel cell may also be installed on trains and ships and it can be used in any long-distance mobility scenario.