Saint-Gobain American Seal and Engineering has focused on resilient metallic seals and sealing systems since 1971. It is this commitment to core products that ensures it delivers sealing solutions supporting customers who are committed to reducing fugitive emissions and improving fuel efficiencies

As emission standards tighten and fuel efficiency demands increase, the transportation industry faces challenging sealing applications that can be solved with resilient metal seals. Saint-Gobain American Seal and Engineering has an established record of providing sealing solutions to this industry with a focus on the diesel engine segment. The solutions offered provide reliability as well as competitive advantage with reduced manufacturing and warranty costs. Saint-Gobain American Seal and Engineering has focused on resilient metallic seals and sealing systems since 1971. It is this commitment to core products that ensures it delivers sealing solutions supporting customers who are committed to reducing fugitive emissions and improving fuel efficiencies.

Commitment to Reliability

The company partners with its customers’ engineering teams to solve their most difficult sealing challenges. For example, while collaborating with a major diesel engine OEM that needed help to reduce emissions within a critical deadline in order to avoid facing severe penalties, Saint-Gobain American Seal and Engineering’s team was able to design and develop a solution on time, increasing performance while maintaining current fuel efficiency – a major contrast to its customer’s competitors who experienced a decrease in fuel efficiency. When the new sealing solution was introduced into the production line ahead of schedule, it generated a cost savings for the customer in excess of USD 1 million – an achievement unheard of in the industry at the time.

Partnerships with Customers

The company’s commitment to reliability is driven by its devotion to engineering. “We do not offer off-the-shelf solutions or a ‘one product fits all’ approach to our customers. We offer custom-designed sealing components and sealing systems that are specific to our customers’ application and design envelope. We work closely with our customers’ engineering team at our site, at their research centre or manufacturing facility from project inception through completion to ensure peak performance”, states a company release.

Custom-Designed High-Performance Metal Sealing solutions include:

AmeriSeal™ Lip Seals: This metal lip seal is the company’s patented design that has been widely used for the exhaust manifold slip joint application. The unique design allows for axial and angular misalignments between two manifold sections caused by thermal deflections, machining tolerances or assembly stack-ups. Lip seal can also accommodate some dynamic motion whether rotational or axial. Due to its core material, it can handle critical leakage performance from -100°F (-73°C) to +1,600°F (+871°C) and withstand pressures up to 1,000 psi (68.9 bar). This lip seal technology has proven to be an excellent choice for innovative design engineers of today and tomorrow.

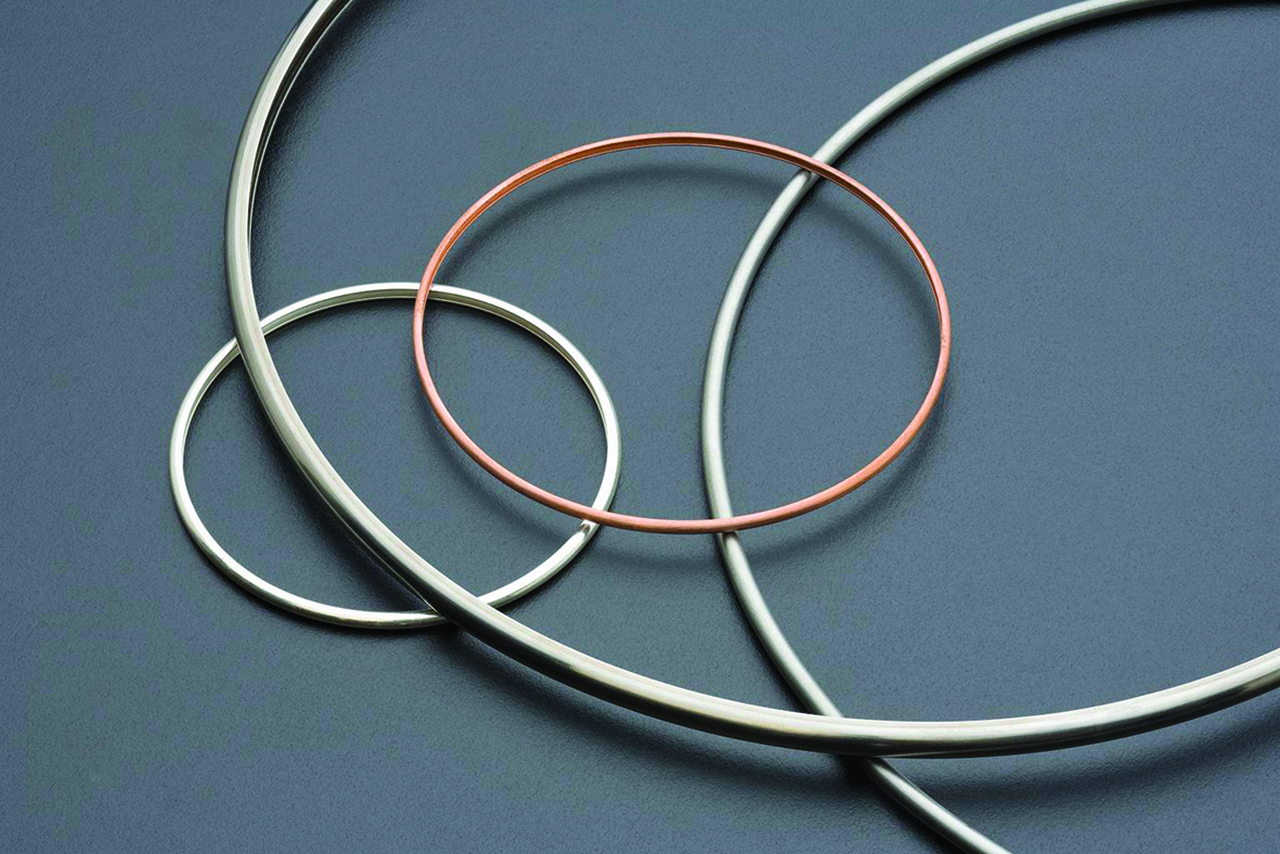

AmeriSeal™ C-Seals: These help overcome both heat and pressure pulsating sealing issues; commonly used in fuel nozzles and to seal between turbocharger compressor and turbine housings. This seal’s high performance is due to spring-back characteristic from the unique C-shaped construction. It can be used for internal, external and axial pressures under extreme conditions that preclude use of gaskets made of organic materials. It is capable of producing relatively high levels of spring-back. Compression of the seal in a controlled groove or between two radial interfaces produces a counter load that generates an effective sealing action ideal for these special applications.

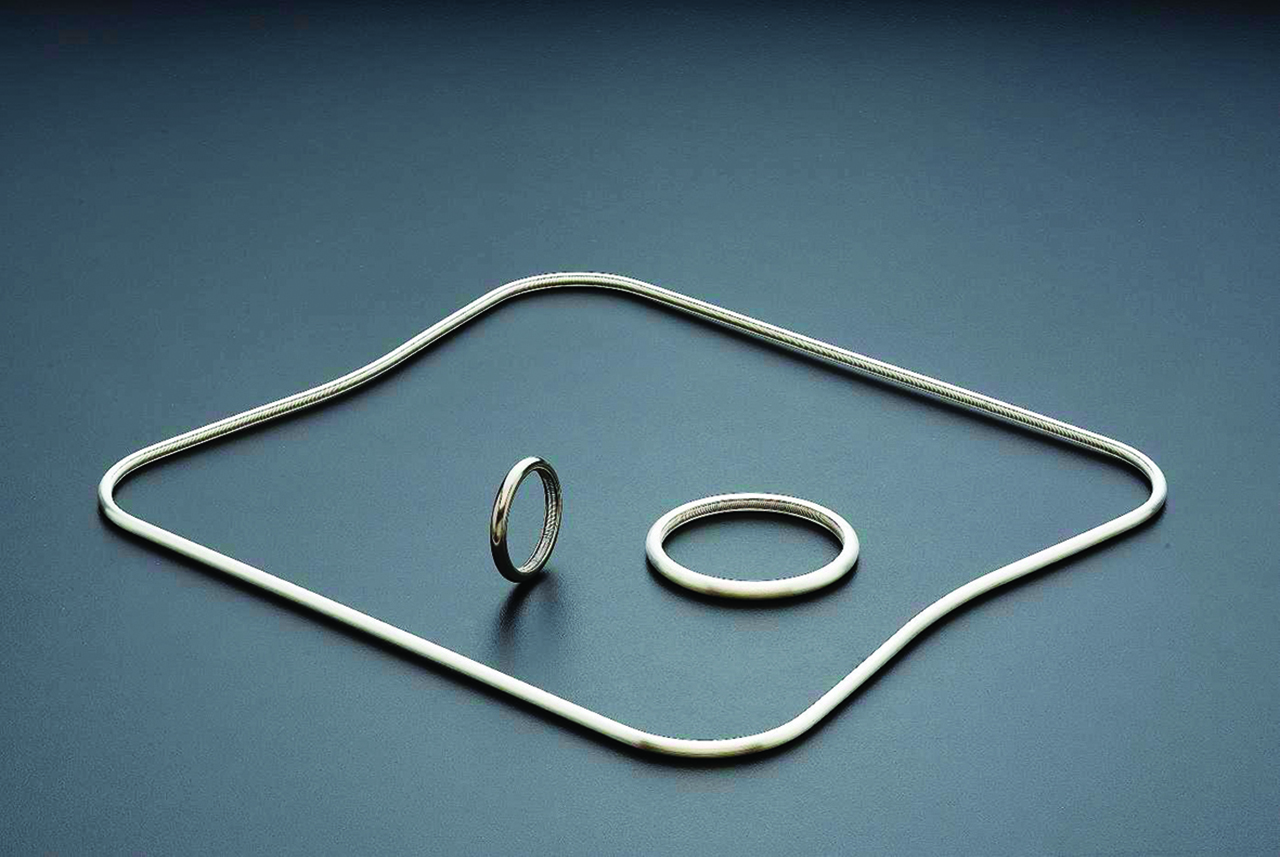

AmeriSeal™ Spring-Energized Seals: These high-pressure seals are suitable for temperatures from cryogenic to 2,000°F (1,093°C) and pressures from 1×10-10 Torr to 1,00,000 psi (6,894 bar). These seals are not affected by corrosion, radiation or other environmental conditions, provided the seal material is compatible with the medium. With its self and pressure-activated design, when the seal is compressed to a predetermined deflection, sealing stresses are generated by the resilient jacket and spring. Seal energisation is achieved when system pressure is introduced, increasing seal loading.

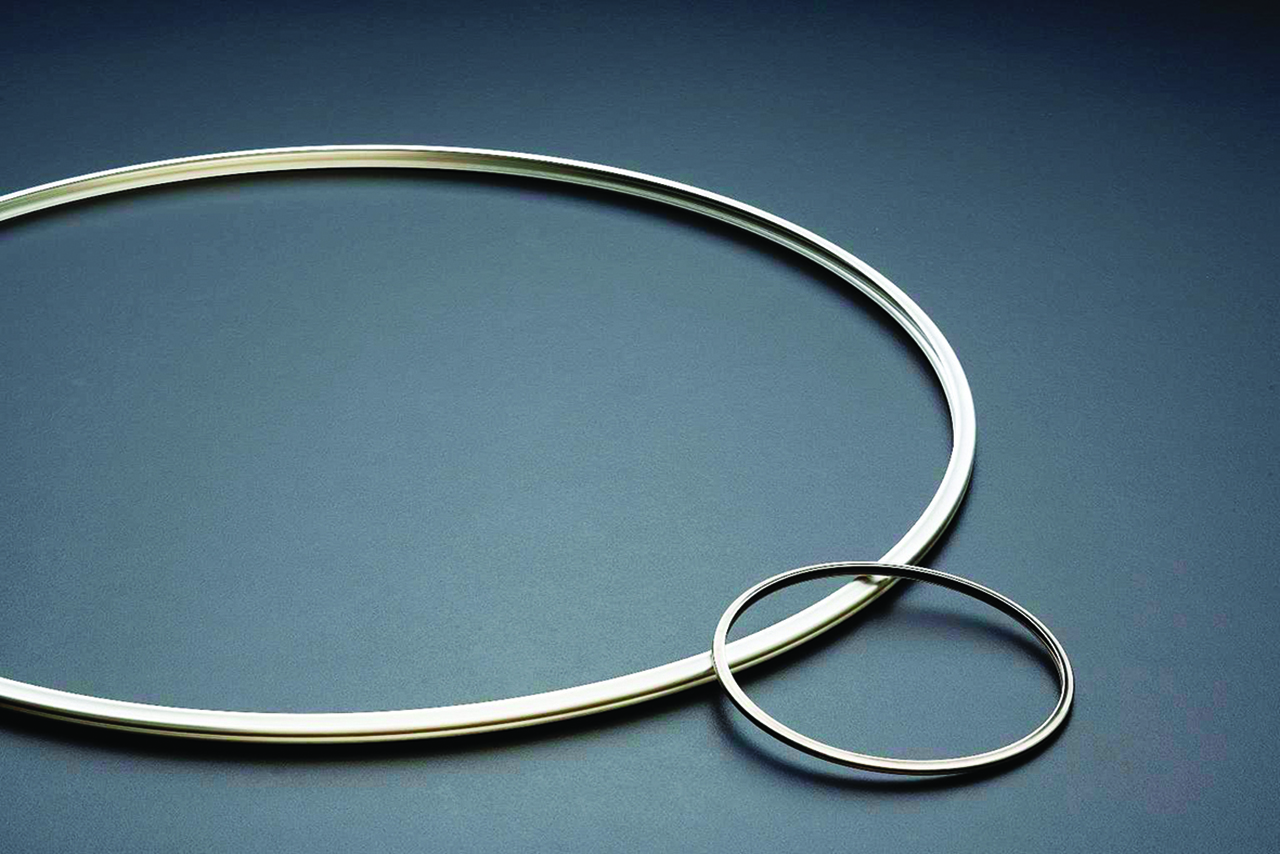

AmeriSeal™ Combustion Seals: These are high-performance resilient metallic seals developed for use as the primary sealing element in combustion environments. With almost 100% useful spring-back and tolerance to flange separation, these seals are well-suited for combustion applications. The jacket is fabricated with a unique forming process using Inconel as the base material. The specially designed jacket and helically wound spring provides a fatigue-resistant gasket to meet the operating limits of temperature, pressure and deflection associated with combustion applications. The primary goal of this unique seal is high resiliency, reliability and product integrity.