“Meritor products being under the chassis products are mostly under abusive conditions, but there is still an opportunity to use lighter alloys and products. Over the years Meritor has developed products using light weight alloys too. For example, the patented STEELite premium drums developed by Meritor are 15-20% lighter than the conventional cast drums while being three times more durable,” says the Meritor duo of Mr. Vittal Raddi, Head – India Engineering & Test Lab, and Mr. Kishan Kumar, Head – Bangalore Technical Centre. Their comments on the subject topic follow.

Excerpts:

Mandatory and other safety requirements in products

Brakes: Meritor is a foundation brake supplier to various OEMs for trucks, buses, trailers and other special vehicle applications. As the speed limits are increasing, brakes are bound to experience increased loads and vibration. Hence in order to protect the brakes from failure, we keep evaluating different materials and processes to protect from severe conditions. In passenger vehicles, braking is the prime and Meritor being the number one supplier of disc brakes in most part of the world, we are planning a range of products in future. Liners are a key to performance and safety of brakes and we are consistently working on them to better the brake performance.

Axles: Axle beam which is a part of the axle is also a critical safety component as it carries complete load of the truck. We have been developing specific high strength materials and special processes to enhance the safety while ensuring the same dimensions of existing beam. Meritor has also developed cast axle beams which are very robust.

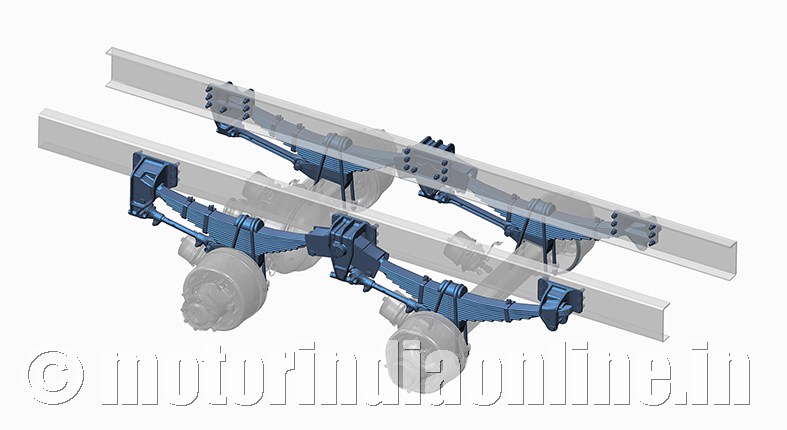

Suspension: Suspension being one of the most critical systems of a commercial truck has direct impact on stability and performance of the vehicle. Meritor slipper suspension for commercial trucks has built-in features that enhance safety and stability of the vehicle. The unique design of leaf spring combined with torque rod system offers not only increased safety & reliability but also provides better tire life & fuel economy.

Safety features and highlights in applications

Brake is an important safety system of any vehicle. Typically issues that can occur with brakes include wrong selection of brake actuators, pneumatic system which actuates the brakes, wrong selection of liners, temperature of the brakes due to frequent braking and vibrations in the vehicle. These issues lead to poor performance and decreased reliability. In case of brake liners, bonding of the liner to shoe and strength to the structural parts are the key to safety of the products. Liners are developed for the specific application which may vary for better braking performance. Also brakes parts are subject to structural failure due to stress and vehicle vibrations on the brakes. Meritor continuously works on these safety features to enhance the product for the demanding application requirements.

Axle beam is subjected to overload and abuse due to poor road conditions. This causes failure of the product and impacts its reliability. Axle beam failure causes loss of control in the vehicle. Another common practice followed in the field is modification on the suspensions which will also reduce the reliability of the product.

Safety apprehensions at higher road speeds

Increase in speed, though is a welcome move for most part of the country, it will be a big challenge to manage our highways. Currently, expressways in India are not protected for public and animal crossing. Also most of our expressways still run through the towns and cities which pose more risks of accidents. While the speed limits are being enhanced, the braking regulations will have to change, mainly the stopping distance. This in turn would bring changes in our products as well.

Meritor proposes its disc brake which typically is developed to reduce the stopping distance with good pressure distribution, maximum pad area for better pad and rotor life. Being fully balanced and incorporating the latest metallurgical developments aids in protection from thermal damage and cracking too. Meritor disc brakes are designed with exceptional braking power that meets federal FMVSS 121 reduced stopping distance (RSD) regulations and European regulation ECER 13 with greatly reduced brake fade resistance for high-demand applications and In-line braking stability for safer, smoother stops.

Light-weighting necessity and trend

Indian commercial vehicle industry is seen to be maturing towards rated load phase vis-à-vis traditional overload usage practices. This will help us to optimize our products further. Also for the fleets, light weighting not only helps to increase the fuel efficiency, but also provides opportunity to increase the payload.

Our recent axle product developments include the 15I and the 12x which will be highly power dense. In all such developments, we are either enhancing the performance of the product by enhancing capability and reliability or optimising the weights or combination of both. Every product that is being developed goes through an optimisation process which uses optimisation software that helps in determining the right amount of material at right location while maintaining the design space.

Also we are introducing the new slipper suspension that allows reduction of overall weight of suspension system by as much as 100 kg (in comparison to the conventional suspensions currently used in India). This being one of the USP of Meritor slipper type suspensions, it is much sought after by the fleets. Similar to all our product developments, our slipper suspension too went through rigorous iterations of optimisation.