In the past few years, robots have considerably contributed to economic growth and prosperity worldwide. “The use of robotics and automation offers outstanding opportunities for stable economic development, high-quality and ergonomic jobs as well as safe and affordable products. Worries about a future where robots snatch people’s jobs away are unfounded. Humans and robots are a winning combination. Even sensational reports to the contrary cannot blind us to this fact,” said Patrick Schwarzkopf, Managing Director of the VDMA trade association Robotics + Automation, at the annual press conference in Frankfurt.

The German robotics and automation sector saw a new record in 2014 by achieving a turnover increase of nine per cent to 11.4 billion euros. In the current year a turnover growth of five per cent is expected.

“Prospects are good that the industry will reach the turnover mark of 12 billion euros by the end of the year,” said Hans-Dieter Baumtrog, Chairman of VDMA Robotics + Automation. In the first four months of 2015, order intake exceeded last year’s level by 11 per cent. Demand came mainly from abroad. In 2014, exports already accounted for 55 per cent. The largest export market is China where investments are increasingly being made in automation technology in order to advance into technologically developed markets in the future.

No paradox – robots and jobs

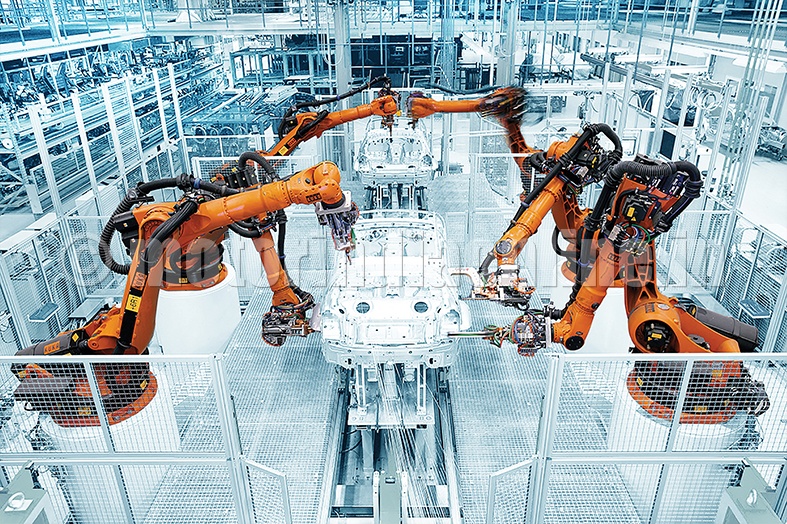

Being by far the largest customer sector, the automotive industry expanded its population of industrial robots in Germany by 15 per cent up to 92,000 units between 2010 and 2014. In the same period its number of employees increased by 10 per cent to 775,000. This shows that the prevailing fear that automation takes people’s jobs away is unfounded. Meanwhile in many instances the direct collaboration of humans and robots is possible. Sensor technology makes robots so safe that they can do without protective fences.

North America is bringing industries back home which it had outsourced to low-wage countries years ago. The Americans realised that a strong industrial basis is important for consistent growth. However, this re-shoring is only possible because enterprises have become more competitive by adopting automation.

ING-DiBa robot study not useful

With its study “The robots are coming – consequences of automation for the German labour market”, the ING-DiBa bank caused a great stir in April. According to the survey, 59 per cent of jobs examined in Germany would be in danger sooner or later due to increasing automation. This would correspond to 18 million jobs. The chances opened up by use of robots for new professions and employments, however, are not quantified. Instead, an unrealistic assessment of technology leads to a distortion of reality.

The authors claim for example that 1.9 million office clerks and secretaries would be robotised, merely 250,000 jobs would remain. “In our view this is not at all a realistic assumption,” says Schwarzkopf.

The German Federal Ministry of Labour has verified the automation potential, not in terms of profession but in terms of tasks performed. The result was that only about 12 per cent of all jobs show a profile with high automation probability.

The study “Robots at Work” published in February last analyses the impact of increasing automation on the economic development of 17 countries. Its authors Georg Graetz of Uppsala University and Guy Michaels of the London School of Economics, however, come to a different conclusion. On average a good 10 per cent of GDP-growth and 15 per cent of the productivity gains were attributable to increased robot use. The experts did not find a reduction of employment but rather an increase of wages. “From this we conclude that technical progress has made human work more valuable”, Schwarzkopf said.

In 2013, the international robot association IFR already discovered in its study “Positive Impact of Robots on Employment” that per robot used, three to five jobs are newly created in manufacturing.

The positive impact can also be seen in the German economy: The robot population increased by almost 20 per cent to 176,000 units between 2010 and 2014. In the same period, overall employment rose by 1.6 million, reaching 42.58 million. In the past five years, one lakh new jobs were created in the mechanical engineering industry alone. This sector currently employs 1,008,000 people.

Record turnover in all sub-sectors

Robotics as a sub-sector of robotics and automation increased its turnover by seven per cent, reaching 3.3 billion euros in 2014. Machine vision, ranging from optical quality inspection to automated toll road enforcement, recorded the largest increase of 16 per cent, reaching 1.9 billion euros. The turnover of integrated assembly solutions, i.e., components and systems for assembly and handling, increased by eight per cent to 6.2 billion euros. In the course of this growth the number of employees in the entire sector rose by three per cent, reaching almost 52,000. It is expected that employment figures will rise considerably in the next years.

According to an IFR survey, more than 225,000 robots were newly installed in 2014. This corresponds to a rise of 27 per cent compared to the previous year. Europe showed a comparatively moderate growth rate of four per cent, whereas North America had a more substantial rate of eight per cent. Installation of robots in Asia increased by 42 per cent, mainly driven by China. “China does not content itself with employing robots. It is the express strategy of the Chinese Government to become a strong and innovative robot country,” says association representative Baumtrog.

The growing interest in robotics worldwide is also reflected in the record participation in AUTOMATICA, the leading trade fair of the industry, taking place in Munich next year. Even today, a year earlier, 91 per cent of the exhibition space has been booked. AUTOMATICA presents the new possibilities of production optimisation: Industry 4.0, human-robot collaboration and professional service robotics.