Leading the way in material handling thro’ truck mounted equipment

The Indian market witnessed the introduction of state-of-the-art truck mounted equipment like Knuckle boom cranes and Hook loaders amongst other diverse solid waste management vehicles during early 2000 when the world leader Palfinger made a high-profile entry partnering C.E.S Onyx, Chennai. Onyx, a leading international player in waste management having bagged the country’s ‘first-of-its-type solid waste management project’ privatisation contract from Chennai Corporation for a period of 7 years, brought in Palfinger, one of its trusted equipment suppliers worldwide, for participation in the challenging assignment. The project was a roaring success and set the benchmark for truck mounted material handling equipment deployment in payload pick-up, transport and delivery at the application site.

There has been no looking back since then and living up to its pedigree as the world leader in many of its operational segments, Palfinger set new standards in the Indian market while maintaining its leadership position. Progress and growth have been achieved thro’ concept selling all thro’ the way to introduce the contemporary technology and material handling methods, utilising a wide range of equipment from its product program. Read on for an exclusive interview with Lilian Clerc, Managing Director Palfinger Cranes India Pvt. Ltd.

Can you brief Palfinger Group’s history and growth timeline in reaching the market leader status in many of its operational segments?

Established in 1932, Palfinger has for many years been among the leading international manufacturers of hydraulic lifting systems as for commercial vehicles and ships. As a multinational company group with its headquarters in Salzburg, Austria, Palfinger has manufacturing and assembly sites in Europe, in North and South America and Asia, as well as over 4,500 sales and service centres located in over 130 countries across five continents. With its nearly 6,200 employees, Palfinger has generated total sales of EUR 935 million in 2012.

Innovation and further internationalisation of products, processes and services form, in addition to greater flexibility, the strategic pillars of the corporate strategy. Greater flexibility enables Palfinger to come up to market development of any kind by fast adaption of resources and capacities and thus assures the company to be successful even in times of high volatility. In line with this strategy, the company today stands for innovative lifting solutions at the interfaces of the transport chain. Its main guiding principle is to make customers throughout the world more successful with our market know-how, technological skills and the commitment of our staff.

Palfinger is technology leader and number one worldwide for loader cranes, EPSILON timber and recycling cranes, container handling systems and cranes in the offshore wind energy industry. Furthermore, the company is one of the leading manufacturers of marine and offshore cranes as well as launch and recovery systems. With railway applications and bridge inspection units, Palfinger is a European technology and market leader in this high-tech sector. Products such as truck-mounted forklifts (worldwide number two), tail lifts, access platforms, truck bodies and pick-up tail lifts complete the product portfolio.

Around 65 per cent of the Palfinger Group is owned by the Palfinger family and around 34 per cent is in diversified holdings. One per cent of shares are owned by Palfinger AG. Since June 1999 Palfinger has been listed on the Vienna Stock Exchange. Since mid-June 2000 the shares of Palfinger AG have also been traded on the OTC market of the Stuttgart, Berlin, Munich, Düsseldorf and Frankfurt stock exchanges.

When and how did Palfinger enter India? And, what has been the growth path in reaching the present position?

Palfinger’s 29th manufacturing facility was incorporated in 2008 in Chennai. However the products were present in India since 2000 supplied directly through Palfinger Asia Pacific and through local dealership. In the initial two years, we prepared our team to do actual sales and support. Further, we started production in July 2010 with 100% localised stiff boom cranes at the Chennai facility and successfully launched two models in the market.

We are continuously bearing the flag of being No.1 in the Indian market and our growth has been leveraged by:

• Having more than five decades of experience of development, manufacturing and distribution of innovative logistics solutions. This counts when we provide solution to customers.

• We are the only global company having the widest product range to offer, light duty telescopic crane (PC series), medium and heavy duty knuckle boom crane (PK series), recycling & forestry crane (EPSILON series) and stiff boom crane.

• Having dedicated manufacturing centre in India.

• Having dedicated R&D, product management and installation specialist providing complete technical solution to clients.

• Having the largest service team and dedicated dealership network supported with specialists from the company side.

• Readily available product stock with minimum lead time for delivery.

These advantages, clubbed with high quality product and manufacturing prowess, we are far ahead of our competition.

In order to leverage our growth further in India we are even looking for strategic acquisitions of related businesses.

What are the products and target application areas for the Indian market?

In India, basically we are offering three types of truck loader cranes to enhance logistics system efficiency. These are:

• Stiff boom cranes: These localized cranes are used by the customers who are looking for a simple lifting and loading solution. These cranes are supplied with a winch mechanism as a standard fitment. We have two variants in this type of cranes, viz., PS 8000 4.0 which is a 8 ton metre crane can lift loads of up to 4 ton at 2 metres distance. Another is PS 13000 6.3 which can lift 6 ton of load at 2 metre distance with ease.

Thanks to the use of high grade steel, Palfinger stiff boom cranes are designed for optimal dead weight, thereby not only providing more lifting power but also creating opportunities for more payload.

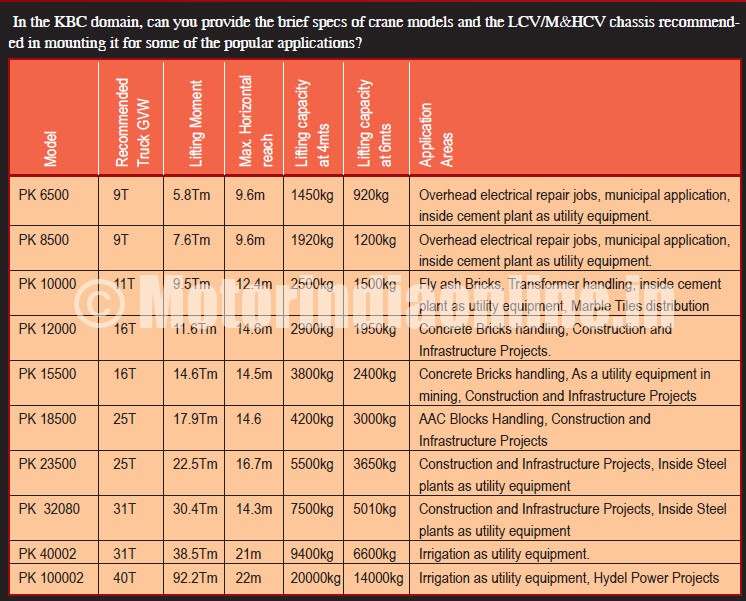

• Knuckle boom cranes (KBC): These cranes have hydraulically articulated telescopic arm which can be folded and occupies minimal space on the truck chassis. These cranes have hydraulic power available at the boom end, thus enabling the fitment of various attachments which can do more specialized jobs than just simple lifting like brick bundle handling, scrap handling, lifting human being to height with man basket, drilling with earth auger, handling loose or waste material with clamshell bucket, etc.

Palfinger is having a wide range of knuckle boom cranes, starting from 0.9 ton metre upto 200 ton metre which can lift load upto 45 ton at 4 metre distance. In India, these cranes are currently imported from Austria.

These cranes carry a successful history of 50 years which makes them highly optimized and technologically advanced. The multi-utility of Palfinger knuckle boom crane makes it the most versatile one available in the Indian market.

• Timber and recycling crane: These are heavy duty and robust cranes specialized for use in process industry where duty hours of cranes are very high. These are very fast and efficient cranes built for severe working environment. In India, these cranes are working successfully in paper mills like ITC, Ballarpur Industries Ltd., etc. These cranes can also be used for various applications like scrap handling in processing units, waste handling at transfer stations, and coal loading and unloading.

Apart from truck loader cranes, we are offering container handling system, i.e., hook loaders in the Indian market. These loaders are used in waste handling applications.

How is the market acceptance of KBC vis-à-vis the pick-n-carry crane (PnCC) that has an impressive offtake of over 10,000 cranes per annum? What are the plans/strategies to corner the market share from PnCC’s dominant hold?

Pick and carry cranes and truck loader cranes are two entirely different products catering to different needs of customers. A truck loader crane is capable of transporting goods from one place to another while imparting an additional advantage of self-loading and unloading to the truck. This solution enhances the efficiency of the entire logistics chain wherein pick and carry cranes are suitable only for loading and unloading jobs.

In recent times we have seen some traditional pick and carry cranes customers working at infra-construction projects like metro rail and inside corporate plants are opting for truck loader cranes basically for two reasons: first, they wanted to transport goods from one place to another without engaging multiple equipments, and the second they are working in areas where safety norms are stringent.

What are the special features and USPs of the products, KBC in particular, for scoring over the competition?

Palfinger’s product quality, highest safety standards, lowest dead weight and manufacturing prowess definitely scores high over the completion, but most importantly our customer-centric approach, international standard installation, round-the-clock service support, readily available spare parts, ready stock of products, dedicated product management, R&D centre, and pan-India dealership network constitute our competitive advantage which is missing with the other players in the Indian market.

Here I want to highlight our most important USP which is our dedicated team, in Palfinger culture we believe on the people, and we are investing a lot of them. I would like to take this opportunity to thank all my team for the great effort they are putting in order to achieve the customer satisfaction. Before doing actual sales in market we largely focused on developing the competency of our team to have technical understanding of our products. This counts when we provide solution and service to our customers. Today I am proud to say that we have the best and most technically adroit team of professionals when it comes to truck loader cranes.

What about the application areas for the hookloader and recycling crane? Can you provide the popular models and the chassis recommended in mounting it for the above applications?

Hook loader is primarily a ‘container handling system’ for the truck. It enables handling of containers or body (concrete mixer, platform to transport heavy machinery) with different sizes and shapes depending upon the customer activity. In India hook loaders are primarily used to handle waste containers in municipal solid waste handling applications.

Recycling cranes

Palfinger Epsilon cranes are used in recycling applications such as scrap and waste handling. These are robust cranes which are made to work in high duty cycle application can withstand high dynamic stress. Currently we are offering Q150L 104 crane on the 25T GVW truck for mobile application and the Q 150 L 72 for stationary application like feeding to compactor or bundling machines.

How do you see the market growth for the above in future? Do you see the hook loader getting increasingly accepted for deployment in construction and infra building applications?

Well, with increasing popularity of mechanised transfer stations in India, I am sure that the market potential for hook loaders is high in future. Currently they are well accepted in municipal waste handling application, but in future they could be used in shifting contraction debris as well.

Please tell us about the sales & service network and of production/assembling facilities for the current product program?

We have a strong sales and service network across all strategic locations in India. Today we have a strong dealership network not only in terms of coverage but technical skills as well. We have a strong focus on developing technical competencies of dealers’ sales service force which is mandatory when it comes to dealing with truck loader cranes.

Currently we have a manufacturing facility in Chennai from where we are producing stiff boom cranes with a capacity of one a day.

What are Palfinger’s plans, if any, to get into full-fledged manufacturing of the popular models for local and export markets?

Seeing our performance in India, our parent group company is willing to do further investment in terms of capital rise and competency development, and recently we have been granted a capital increase in order to accompany our growth and to be prepared for any opportunity in terms of acquisition or full-scale manufacturing whenever we will achieve a certain volume of product.

Depending on the market demand, we are open to bring other Palfinger products from global offering to India provided we are well prepared in terms of technical understanding, after-service and spares support. Here I want to reiterate that we are even open for acquisitions of some related businesses which we think will further leverage our growth in India.

Can you provide the market size and share for Palfinger products?

As of now there are no concrete stats available about the market size, and every player in the market has his own version. With some research done on this subject, I can say the market size for truck loader cranes in India in 2012 was around 300-350 units, and we have been in the leading position with a 60 per cent market share.

How has the dip in economy in general and the CV segment in particular impacted your sales? How do you see the growth rate for your products in the years to come?

I will confess here that the gloomy economic situation and dip in CV industry sales (almost -30 to 35 per cent in our segment of truck >25t GVW) has not largely affected us, and still we are on the growth track while achieving our targeted volume in spite of all odds. We have increased significantly our sales in 2013 vs. 2012 in spite of the downturn which obviously is a good sign for the future. Moreover, in this market we succeed to come close to breakeven with some month in advance compare to our road map.

With increase in awareness, how Palfinger products are changing the logistics scenario in India and making it more efficient and profitable we can surely see the bright future of our product in coming years.

What are the new products likely to be positioned for the Indian market in the near future?

As I have already said, if the market demands we are ready to offer products from our global offering but only after we have acquired exhaustive technical knowledge and thus ready to support customers in terms of after-service and spares. The Palfinger’s portfolio is definitely huge. It has aerial work platforms, marine crane, windmill crane, truck mounted forklift, tailgate, rescue crane on boat, hook loaders, etc.