By Arun Kumar, Managing Director of Firestone Industrial Products – Asia and Steve Street, International and North American Heavy Duty Spring Development Manager, Firestone Industrial Products

Recent nationwide improvements in bus transport include Bus Rapid Transit (BRT) systems, which provide high-speed, high-capacity buses for more efficient travel within cities, as well as new inter-city buses with luxury accommodation. Many Indian transport corporations have also met the accessibility and comfort needs of travellers with appealing amenities such as low-floor buses for disabled passengers and air-conditioned buses. Demand for these new amenities has been driven by a growing number of passengers willing to pay extra for a more comfortable bus ride.

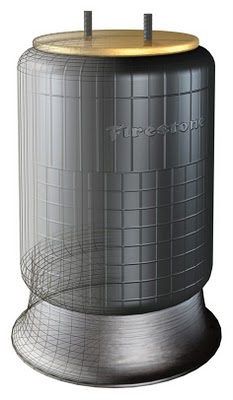

To create a more pleasant experience for the passenger, the transportation industry is embracing the use of air spring suspensions, a feature found on approximately 20 to 25 per cent of new buses in India today. With air spring-equipped buses now becoming more common throughout India, it is critical for bus line personnel and mechanics to become more skilled at air spring specification and maintenance. Proper specification and maintenance can have a significant impact on the longevity and performance of air springs, which offer a whole range of benefits for bus travellers, transportation companies and the national infrastructure.

Higher ride comfort

A bus equipped with an air spring suspension provides a considerably smoother and more comfortable ride than one with a traditional leaf spring suspension. The air spring improves the ride and the handling of the vehicle by providing a contained column of air between the axle and vehicle frame that, when used in conjunction with a damper, offers excellent isolation from road inputs. This superior isolation increases the comfort of bus drivers and can provide a more comfortable ride for weary travellers, making longer distances more tolerable. Passengers too are more satisfied, as they are able to avoid the discomfort of bumps on the road.

Unlike steel leaf spring suspensions, air springs can provide a close to constant natural frequency, regardless of the passenger load; hence the quality of the smooth ride is maintained regardless of load condition. Buses with leaf spring suspensions are more likely to give a harsher ride if there are a few passengers on board. By automatically increasing or decreasing air pressure in the spring to adjust to each specific load, air spring suspensions will always provide a comfortable ride. Less wear on roads

Less wear on roads

Upon completion, India’s massive National Highways Development Project (NHDP) will offer 66,590 km of new roads and improved existing roads, at an estimated cost of $13.2 billion (Rs. 54,000 crores). In order to protect this substantial investment, it is important to explore the best ways to maintain these roads and ensure their longevity. Since heavy-load vehicles such as buses and trucks are typically responsible for 50 per cent of road maintenance costs, one solution is to minimize the wear that these vehicles put on roads. This is another area where air spring suspensions can be of assistance.

Studies have shown that heavy-load vehicles equipped with air springs tend to cause less stress on road systems, as they exert less pressure than vehicles with traditional suspensions. In fact, a study done by the Organization for Economic Co-operation and Development (OECD) reported that the use of air spring suspensions on motor vehicles increases pavement life by 15 to 60 per cent. Longer pavement life means significant reduction in road maintenance costs, which often comprises 90 per cent of annual road budgets in OECD countries such as India.

In order to get the best performance from air spring suspensions and maximize useful life, it is important to ensure they are correctly installed and maintained. This begins with the proper specification of air springs for buses.

Air spring specification

When specifying air spring suspensions, bus companies must first consider three prominent factors – the size of the loads that the bus will be expected to carry; the terrain the bus will travel over and how much deflection this will cause in the air spring; and preventable causes of air spring wear.

Bus manufacturers are encouraged to work closely with their air spring suppliers during the suspension design concept to make sure the correct air spring selection is made with regard to bellows compounds, piston and top plate materials, together with surface treatments to provide corrosion resistance.

Depending on the bus specification and its intended application, suspension formats basically fall into two categories: (i) luxury type buses, which can have a three axle set-up, front, drive and tag axles, two air springs on the front axle, four on the drive and two on the tag; and (ii) inner-city type buses typically having two axles; the front fitted with two air springs and the rear drive axle having four.

Axle weight ratings and load distribution between axles will depend on the bus application and the location of the engine. Historically Indian buses have utilized front engines which resulted in high floor/deck heights, making passenger access cumbersome. However, the new generation of low-floor buses improves access and embraces rear engine technology. Buses fitted with air springs can capitalize on electronic control systems that allow the bus to kneel to curb height to further improve access.

For buses that will travel over rougher terrain, it is important to select the most durable air springs which are adequately sized for the axle rating. Regular travel on rough roads will put more wear on the air springs, as they see more stroke and endure higher internal jounce pressures, and they may need to be replaced more frequently.

Sometimes, the source of wear and tear is on board the bus, in close proximity to air springs. The heat generated by the engine, exhaust and brakes, both positioned close to air springs, can have a negative effect on their longevity. Bus companies can reduce heat damage by specifying heat shields – usually a plate of steel – for installation between the exhaust and brakes and air springs.

With a growing number of air spring suspensions

being specified, it’s increasingly crucial for bus drivers and auto mechanics to learn more about the proper maintenance of air springs.

Maintenance

The lifespan of air springs varies, depending largely on the loads they carry, the terrain they travel and the amount of their exposure to heat, dust and debris. Some air springs may last up to five years. Those in heavier duty cycles, though, with ample dust, debris and frequent stops and starts may only last one to three years before needing replacement. In order to get the best performance and longest life from their air springs, bus lines must make sure that the air springs are well maintained.

A proper air spring inspection, however, involves more than merely scanning the air spring for punctures and abrasions. It is essentially an inspection of the entire air spring suspension system, as air springs work in close proximity with other parts of the suspension as a unit. Though there are no set industry standards on how often to inspect air springs, there are a variety of recommendations on the topic from air spring and air spring suspension system manufacturers.

With trucks, drivers are encouraged to perform simple visual inspections on air springs weekly, to look for any abrasions, build-up or punctures, as these air springs are positioned higher and are more accessible. Buses, however, are much lower to the ground, making such inspections more difficult for bus drivers.

Bus drivers can, however, occasionally wash beneath the bus with a power washer and watch for certain signs such as cracks, which may indicate a leak and the need to replace the air spring, or a significant decrease in ride comfort. Drivers should also check air springs for sufficient and equal pressure and make sure that the suspension is set at proper ride height. If the bus appears tilted, uneven or is showing any other signs of leakage, it should be taken to a mechanic for service. Inspection

Inspection

Fortunately, with the growth of India’s infrastructure, there are now plenty of auto service centers at frequent intervals along roadways. It is recommended to take an air suspension-equipped bus to these service centers for a thorough physical inspection in line with the manufacturer’s service manual, making sure that the correct service intervals are strictly adhered to. These include a visual inspection of the air springs for abrasions, punctures, dust and debris, plus a more in-depth examination of the rest of the air spring system. The air springs should be fully inflated during these inspections and examined closely for leaks. If the inspector notices even the slightest air leak, the air spring will need to be replaced. The mechanic should also check to ensure that there is sufficient clearance around the complete circumference of the air spring when it is inflated to its maximum diameter.

After inspecting the air springs, the mechanic can move on to other related parts of the suspension system. First, mechanics should check the suspension’s air lines to make sure that they are functioning properly and correctly secured. At no time should these lines come into contact with the outside of the air spring. Loose air lines can quickly rub a hole in the bellows of the air spring.

The next step is adjusting the air suspension ride height, if needed. All vehicles with air springs have a specified ride height established by the original equipment manufacturer. Found in the manufacturer’s service manual, this height should be maintained within approximately 6 millimeters. The dimension can be checked while the vehicle is loaded or empty. Mechanics should also look at the height control valve to make sure it is functioning properly.

Next, it is important to make sure the suspension system has the proper shock absorbers and that they are functioning correctly. Mechanics should check also for leaking hydraulic oil and worn or broken end connectors. If the mechanic finds a broken shock, he should replace it immediately. Shock absorbers will normally limit the rebounding of air springs and keep them from overextending.

The mechanic’s next step is to check for loose or worn suspension bushings, as they may lead to improper alignment and increased wear or damage to its mating components. Finally, it’s essential to check the tightness of all mounting hardware, or nuts and bolts. If the mechanic finds them loose, they must retorque the nuts and bolts to the manufacturers’ specifications, being careful not to over-tighten them.

With proper installation and maintenance, air springs can be expected to provide comfortable travel to the end user for a longer period of time.

With air springs gaining popularity in Asia over the past decade, India’s buses have benefited from the use of a suspension component that is time-tested and proven. To get the best performance out of air springs, it is important to take good care of them. By taking responsibility to keep the air springs of their buses properly maintained, bus line owners can expect a longer air spring life and stronger performance, as well as happier passengers enjoying the smooth, comfortable ride that air springs provide.

This is also beneficial for the Government, as well maintained air springs will help heavy vehicles lighten their impact on the new roads.