As a world-leading producer and supplier of safety-critical systems for the commercial vehicle industry, JOST is a specialist for components that link trucks and trailers. And this link is now being revolutionized with the new KKS automatic coupling system that enables the driver to couple and uncouple the semi-trailer via remote control – automatically, safely and quickly. Therefore, fleets can increase efficiency, convenience and safety with one single product. All this makes the KKS the future of logistics and a key component in autonomous driving.

Intelligent end-to-end system

Coupling and uncoupling a trailer is still a lengthy, expensive and hazardous procedure. The truck driver has to be aware of many different things, each of which are time-consuming and pose a hazard to health and safety. According to figures from the DGUV (German Social Accident Insurance), professional truck drivers suffer falls quite often. Simply getting in and out of the cab can result in such an accident, potentially causing injury.

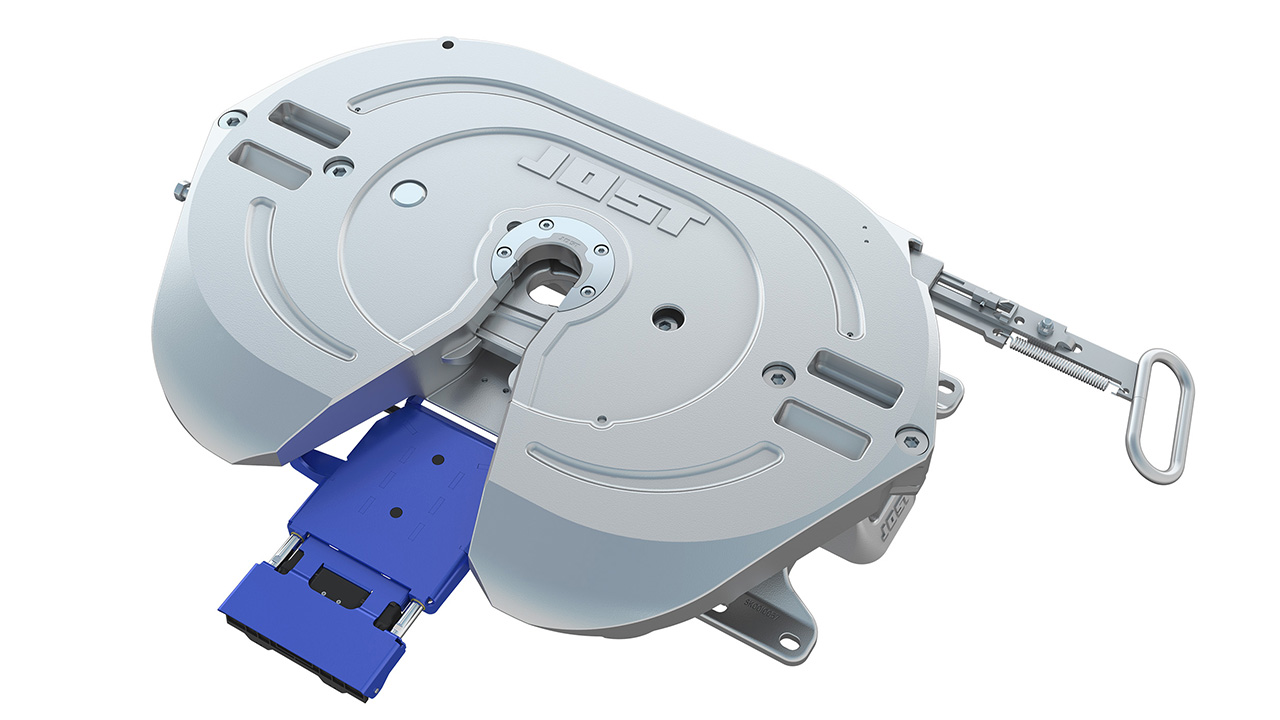

As the global market leader for fifth wheel couplings and landing gears, JOST is providing a smart solution for the future of coupling with its KKS automatic coupling system. The KKS 42 fifth wheel coupling, Modul E-Drive electric landing gear, sensor coupling system, 3-sensors, LubeTronic automatic lubrication system, KKS remote control and the ISO 13044-2-certified KKS connector all combine to form an innovative system for the coupling process.

Automatic coupling and uncoupling

The driver is guided through the coupling process, with sensors providing live information on the KKS remote control throughout every step of the process. With the KKS, the driver no longer needs to climb out from the cab, crank down the landing gears, climb behind the cab, unplug the spiral cables and pull the fifth wheel open when uncoupling. Instead, the Modul E-Drive electric landing gears automatically deploy at the push of a button and the fifth wheel is unlocked remotely. This eliminates the danger caused by climbing on and off the catwalk, as the spiral cables for air, electrics and ABS/EBS no longer need to be detached manually: the KKS connector on the fifth wheel and trailer detaches all the necessary electrical and pneumatic connections between the truck and trailer.

For the coupling process, the driver raises the vehicle chassis to bring the fifth wheel coupling plate into contact with the trailer support plate. Equipped as standard, the support plate sensor indicates that the trailer plate is touching. Once this information is displayed on the KKS remote control, the truck is reversed until the king pin has securely engaged in the lock of the fifth wheel coupling and the mechanism closes. The position of the king pin and the correct locking of the fifth wheel coupling are also monitored by sensors and displayed to the driver on the KKS remote control. Together with the mechanical connection via the king pin, the KKS connector also automatically connects the air, electrics, ABS and EBS.

More efficiency through KKS

Using a KKS can cut the time required to change a trailer by up to 50 percent, as there is no need to manually crank the landing gear, connect the supply lines or open the fifth wheel coupling. The KKS significantly reduces the total costs for each circuit, with savings of up to 50 percent possible during the coupling and uncoupling process. It is particularly well suited for transport companies which perform coupling processes often and drive short distances, such as those in on-site transport, as the time saved here really pays off financially. Another application is the transport of goods where safety plays a key role, such as hazardous goods, as the sensor monitoring guarantees a high level of security against trailer losses and incorrect coupling. The KKS is also an ideal solution for transport between production sites and logistics facilities. Errors or damage caused during the coupling process are eliminated almost completely thanks to remote operation and monitoring through the KKS. For example, the Modul E-Drive landing gear is always fully retracted automatically. Moreover, the KKS reduces the probability of trailer losses due to erroneous operation, damage and occupational accidents to virtually zero. The KKS system can be introduced to mixed fleets step by step.

Safer and ergonomic workplaces

The KKS makes all the physically demanding tasks of the coupling process a thing of the past, as well as ensuring that this process is no longer dependent on the weather or time of day and significantly reducing stress. A standard pneumatic cylinder opens the fifth wheel coupling effortlessly, even when the tractor- trailer is twisted. The automatic coupling process means that the driver does not have to climb in and out of the cab as often, nor climb onto the catwalk – two factors that significantly reduce the potential for injury. These benefits mean the KKS opens up new possibilities for a more diverse driver pool; as such, JOST is providing an answer to demographic change and the lack of specialist workers.

—

Contributing to the future of logistics

Joachim Dürr, CEO of JOST Werke AG, is thoroughly impressed by the KKS automatic coupling system: “The innovative KKS provides our customers in the highly competitive logistics sector with clear benefits with regard to safety and efficiency. And the drivers also benefit, as using the KKS significantly reduces the risk of injury during the complex coupling process while simultaneously making it more convenient. I am delighted that we are taking a big step towards highly automated, convenient and safe logistics solutions with this system and are making our contribution to autonomous driving as a supplier.”