“We have started initial supplies to Tata Motors and are in discussion with all the major commercial vehicle manufacturers including Ashok Leyland, Volvo-Eicher, MAN-Force, AMW and also with Mahindra-International and Daimler-Hero for supplying our products”, say Mr. Amarjeet Singh, CEO of Jost India Auto Components Private Ltd.

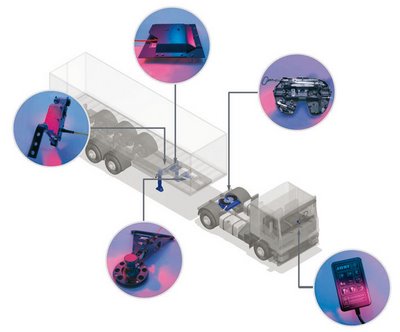

Jost will manufacture fifth wheel couplers for the Indian market. The fifth wheel essentially provides the link between the tractor and the trailer. The coupling consists of a coupling pin (or king pin) on the front of the semi-trailer and a horseshoe-shaped coupling device called a fifth wheel on the rear of the towing vehicle (tractor).

Mr. Peter Ormond, President Jost Asia, maintained, “We are committed to the Indian market and we aim to equip many generations of new trucks and trailers in India with our safe and reliable systems.”

Jost is the worldwide leading producer of vehicle connection systems, modules and components for truck & trailer. Under the umbrella brand name of Jost, the comprehensive range of products is subdivided into three areas. The Jost brand includes fifth wheel couplings, telescopic landing gears and accessories for semi-trailers, ball bearing turntables, king pins and container locks and components for alternating systems. Under the traditional brand name of Rockinger, the company produces towing hitches and drawbar eyes for both transporters and trucks, as well as for use in the agricultural industry. With Regensburger Zuggabel, Jost completes its range of products for coupling technology with towing drawbars for both road and agricultural use. JOST is the only supplier that can provide its products and services throughout the world. The company is located everywhere, with distribution, production and development in all continents. With production plants in Germany, Spain, Hungary, Poland, Romania, the US, Brazil, South Africa, China and India, Jost employs around 2000 employees worldwide. “As an integral part of the Jost Group, we at this new plant will contribute to the success and growth of the Jost World. The top quality, engineering excellence and the ‘Made in India’ label will all guarantee a high level of acceptance of Jost products from the very outset,” said Mr. Singh.

“As an integral part of the Jost Group, we at this new plant will contribute to the success and growth of the Jost World. The top quality, engineering excellence and the ‘Made in India’ label will all guarantee a high level of acceptance of Jost products from the very outset,” said Mr. Singh.

“In order to be more versatile in our operations in India, we have, apart from offering products decided to extend value added services as well. Our E-Coating plant is probably one of the very few and the best available in India. Enough spare capacity has been planned for an uninterrupted service to customers preferring to E-Coat their components. Proximity would benefit many Tata ancillaries and other companies in Jamshedpur. Needless to mention, customers from other states would also be serviced, should there be a need”, he added.

E-Coating (technically referred to as Cathodic Electro Deposition) is a method of painting which uses the D.C. Voltage to deposit paint on the substrate. This process guarantees the best corrosion protection working on the principle of opposite attraction. The paint particles are drawn to the metal part and are deposited on the substrate, forming an even continuous film over the surface, in every crevice and corner, until the coating reaches the desired thickness. The plant, covering an area of 60,000 square metres, is close to Tata Motors’ factory with which Jost has already got into a long-term agreement for supply of fifth wheel couplings. The new Jost facility in Jamshedpur is spread over a 15-acre plot of land out of which only 5 acres has already been utilized. There is sufficient space for future expansion.

The plant, covering an area of 60,000 square metres, is close to Tata Motors’ factory with which Jost has already got into a long-term agreement for supply of fifth wheel couplings. The new Jost facility in Jamshedpur is spread over a 15-acre plot of land out of which only 5 acres has already been utilized. There is sufficient space for future expansion.

The company has set up a very modern manufacturing facility fully equipped with heavy-duty press shop, welding lines, CNC machines and an e coating plant. The company has set up 5 heavy duty CNC hydraulic presses with varying capacity of 1200 to 300 tonnes. The sheet metal work is done completely in house. The welding process is again a key element of the manufacturing process as the fifth wheels are mostly fabricated. All the welders are NTTF trained and have been given rigorous on the job training. A specific mention needs to be made about the ultra-modern plant for e-coating (KTL). This process of cathodic deposition of paint (CED) ensures that all JOST products remain protected against corrosion, and is absolutely health and environment friendly. In fact Jost has been able to achieve 0 ppm levels on its supplies to Tata Motors.

Globally, Jost offers both cast and fabricated version of fifth wheel couplers. The European market is primarily using cast version but in India the manufacturers prefer to go with a fabricated version. Jost products have already been tested under Indian conditions and have been found satisfactory. Jost has been selected by Tata Motors for the World Truck and Novus projects.

Globally Jost is an OEM to most of the truck majors like Daimler, MAN, VOlvo, Scania and International. With most of these manufacturers setting up their business in India, Jost sees a good opportunity for future growth in the Indian market, says Mr. Peter Ormond. The company is talking to all the truck majors including Ashok Leyland, Volvo-Eicher, Mercedes, MAN, AMW and Mahindra International. Apart from fifth wheel, Jost India also offers many other products for the trailer segment which includes landing legs, king pins and towing hitches. Initially these products will be imported and sold through Jost’s distribution network across India. The company is in the process of establishing its sales and service network both for the fifth wheel and other products and by the end of the year it plans to appoint 10 distributors across India, says Mr. Amarjeet Singh.

Apart from fifth wheel, Jost India also offers many other products for the trailer segment which includes landing legs, king pins and towing hitches. Initially these products will be imported and sold through Jost’s distribution network across India. The company is in the process of establishing its sales and service network both for the fifth wheel and other products and by the end of the year it plans to appoint 10 distributors across India, says Mr. Amarjeet Singh.

Jost is also planning to conduct camps to educate fleet operators on the importance of lubrication and maintenance of the fifth wheel and other products. The fifth wheel is a vital link between the Tractor and the trailer.

But if there is one glitch in the whole story, it is the unexpected downturn in the Indian commercial vehicle industry, particularly in the tractor-trailer segment. Just when the Jost India facility was getting ready to move into fledged manufacturing, the sudden downturn in the tractor-trailer industry played spoil sport as the business is completely dependant

on the growth of tractor-trailer segment.

Mr. Amarjeet observes: “We are glad this unexpected downturn has happened at the initial stage of operations. We are using this time to get our systems and process in place. We are implementing an ERP system and also working towards TS certification. By establishing these systems and procedures from day 1, we want to inculcate a new culture by investing on the best of manufacturing practices so that we don’t have to think of bettering our process at a later stage. The products manufactured in India have been approved by Josts’ global facility and the quality of these products would be the same as across all manufacturing facilities worldwide”.

Globally Jost clocked a turnover of Euro 500 million in 2007. It has been adding products to its global portfolio by acquiring companies and products which add value to its existing portfolio like the recent acquisition of ‘Tridec’ which specializes in systems for forced steering and independent wheel suspensions. Globally Jost is growing in many of the markets. China and Brazil are currently the important and fast growing markets for Jost. India would soon join the list.

Mr. Peter Ormond says: “We see Jost India play a larger role in the global business of Jost. We have invested in India for the long term and we see good growth potential in India in the next 5 to 10 years. We are also looking at the opportunity of using the Indian plant for manufacturing and exporting fifth wheel couplers to other nearby markets. But the first priority is to cater to domestic demand and at a later stage we will consider the prospects for exports”.

The company has so far invested close to 6 million Euros in the Indian plant and is targeting volumes of 30, 000 units in the next couple of years. A lot depends on the growth in tractor-trailer segment. As the roads better, there will be more demand for higher tonnage vehicles which can carry loads over long distances.