It is rare in these days of difficult Indian economic situation to come across companies associated with the automotive CV sector  announcing a high double digit growth rate and planning to better it in the years to come. One such sterling performer amongst this current rare breed has been Interpump Hydraulics India Pvt. Ltd. (IPH India), Hosur, Tamil Nadu – a wholly owned subsidiary of Interpump Hydraulics S.p.A. Italy, which is in turn a 100% subsidiary of Interpump Group, Italy, a billion dollar global player and a leader in many of the products under the hydraulics and water business segments. “We have already crossed the last year sales turnover and hope to register a growth rate of around 20% in our financial (calendar) year ending Dec. 2013”, says Mr. Girish Garud, Managing Director, IPH India. In order to understand the product program, and the background behind the impressive performance in the recent times, we met Mr. Garud and his team at their works office, Hosur, Tamil Nadu, where buoyed up by the consistent high growth rates and increase in top and bottom lines, he has chalked out expansion programs to touch Rs. 2,000 million mark in about 4 year time period”.

announcing a high double digit growth rate and planning to better it in the years to come. One such sterling performer amongst this current rare breed has been Interpump Hydraulics India Pvt. Ltd. (IPH India), Hosur, Tamil Nadu – a wholly owned subsidiary of Interpump Hydraulics S.p.A. Italy, which is in turn a 100% subsidiary of Interpump Group, Italy, a billion dollar global player and a leader in many of the products under the hydraulics and water business segments. “We have already crossed the last year sales turnover and hope to register a growth rate of around 20% in our financial (calendar) year ending Dec. 2013”, says Mr. Girish Garud, Managing Director, IPH India. In order to understand the product program, and the background behind the impressive performance in the recent times, we met Mr. Garud and his team at their works office, Hosur, Tamil Nadu, where buoyed up by the consistent high growth rates and increase in top and bottom lines, he has chalked out expansion programs to touch Rs. 2,000 million mark in about 4 year time period”.

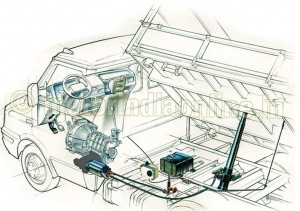

Interpump Group worldwide, has two mainstream business operations – ‘Hydraulics business’ and the ‘Water business’. ‘Interpump Hydraulics’ (IPH) is in charge of hydraulics business which has many leading global companies in its fold, and also under which is its subsidiary IPH India, one of its five worldwide manufacturing locations. The water jetting business also has various reputed global brands, and the Interpump Group is the holding company of these businesses, registered in Milan stock exchange. Roughly 60% of the Interpump Group sales turnover comes through the hydraulics business and the balance through the water business. About 50 companies worldwide come under its fold and the growth has been rapid both through the organic and inorganic expansions. In the last 6 months, the group has acquired Hydrocontrol S.p.A. Italy, a valve manufacturer and I.M.M. Hydraulics S.p.A. Italy, hoses & fittings manufacturer to consolidate its hydraulics group’s supply program. “The company can supply from in-house, about 90% of the hydraulics products for the customer requirements starting from PTO (Power-take-off), hydraulic pump, cylinder, valves, hoses, and the balance items, are sourced from other vendors. All the manufacturing locations are interlinked through an advanced ERP system so that the marketing efforts are coordinated for timely supplies at competitive rates,” adds Mr. Garud.

Interpump Group worldwide, has two mainstream business operations – ‘Hydraulics business’ and the ‘Water business’. ‘Interpump Hydraulics’ (IPH) is in charge of hydraulics business which has many leading global companies in its fold, and also under which is its subsidiary IPH India, one of its five worldwide manufacturing locations. The water jetting business also has various reputed global brands, and the Interpump Group is the holding company of these businesses, registered in Milan stock exchange. Roughly 60% of the Interpump Group sales turnover comes through the hydraulics business and the balance through the water business. About 50 companies worldwide come under its fold and the growth has been rapid both through the organic and inorganic expansions. In the last 6 months, the group has acquired Hydrocontrol S.p.A. Italy, a valve manufacturer and I.M.M. Hydraulics S.p.A. Italy, hoses & fittings manufacturer to consolidate its hydraulics group’s supply program. “The company can supply from in-house, about 90% of the hydraulics products for the customer requirements starting from PTO (Power-take-off), hydraulic pump, cylinder, valves, hoses, and the balance items, are sourced from other vendors. All the manufacturing locations are interlinked through an advanced ERP system so that the marketing efforts are coordinated for timely supplies at competitive rates,” adds Mr. Garud.

IPH India Operations

IPH started its Indian operations during 2006, essentially as a trading outfit. After the entry, all the supplies from constituent  companies have been co-ordinated and channeled through IPH India, and the growth in the initial years were centred around supplies to a particular OEM, viz., Ashok Leyland Ltd.

companies have been co-ordinated and channeled through IPH India, and the growth in the initial years were centred around supplies to a particular OEM, viz., Ashok Leyland Ltd.

Even today its major customer remains Ashok Leyland, however the market share has increased due to the addition of other OEMs over the past few years and parallely a dealer network expansion is also effected. “We have already made inroads with supplies to Tata Motors and are working with other prominent OEMS for PTO & pump supplies. Our goal is to capture in excess of 90% market share for the PTO & pump supplies to the Indian market. It’s an ambitious yet feasible goal as the OEMs are keen to supply factory fitted PTO & pump and demand competitive rates – and this is apart from the default terms of consistent high quality and service support. This is possible  only by a company that has a manufacturing base in India and the support of a global technology in the field, who can provide PTOs for any commercial vehicle transmission and to the specs of the OEM”, explains Mr. Garud. He also adds that IPH has a major share of worldwide market and can readily supply PTOs for myriad gear boxes of various OEMs to their specifications from any one of their manufacturing locations, which is one of the significant strengths of IPH.

only by a company that has a manufacturing base in India and the support of a global technology in the field, who can provide PTOs for any commercial vehicle transmission and to the specs of the OEM”, explains Mr. Garud. He also adds that IPH has a major share of worldwide market and can readily supply PTOs for myriad gear boxes of various OEMs to their specifications from any one of their manufacturing locations, which is one of the significant strengths of IPH.

IPH has three manufacturing plants in India, two in Hosur, Tamil Nadu, and one in Rudrapur,  Uttarakhand. “Our Rudrapur plant was essentially set-up to meet the requirements of Ashok Leyland which opened its manufacturing location in Pantnagar, Uttarakhand. The facility is currently manufacturing PTOs, pumps and tipping kits which are produced in a cost effective way making our products more competitive especially in the supplies to price sensitive markets. A lot of synergy is happening in the new facility that has a manufacturing capacity of 50,000 PTOs & pumps per year in addition to other products. Cylinders which used to be imported from Italy are also now produced at the Hosur plants and supplied to all customers. In the coming years, IPH India would be a prominent player in Indian truck hydraulics segment, and this is in addition to becoming a major manufacturing base for IPH global operations”, briefs Mr. Garud.

Uttarakhand. “Our Rudrapur plant was essentially set-up to meet the requirements of Ashok Leyland which opened its manufacturing location in Pantnagar, Uttarakhand. The facility is currently manufacturing PTOs, pumps and tipping kits which are produced in a cost effective way making our products more competitive especially in the supplies to price sensitive markets. A lot of synergy is happening in the new facility that has a manufacturing capacity of 50,000 PTOs & pumps per year in addition to other products. Cylinders which used to be imported from Italy are also now produced at the Hosur plants and supplied to all customers. In the coming years, IPH India would be a prominent player in Indian truck hydraulics segment, and this is in addition to becoming a major manufacturing base for IPH global operations”, briefs Mr. Garud.

To meet the increasing demand for its products, IPH India with the support of its parent company is re-organizing its manufacturing operations. In this regard major investments are being done to add various machining centres, special grinding machines etc. similar to those in Italy to meet the production demands and maintain quality norms. The workforce has been trained in operations both locally and in Italy to meet the global standards for the products being manufactured. Also, the company is on the look-out for acquiring its own premises to establish advanced manufacturing facilities and augment their expansion program.

“In line with our restructuring program, we will manufacture PTOs & pumps at Rudrapur plant while  Hosur will focus on hydraulic cylinders and water jetting business. Apart from gearing up on the manufacturing front, we will also be expanding our dealer network to support the aftermarket demand of spares as well as sub-assemblies for new vehicle building”, points out Mr. Garud. “Our re-organisation is taking into account, all these factors so that our business strategy of increasing the market size and share along with the building of a robust aftermarket segment to the current OEM business will keep the organisation on a healthy growth path even in these testing times”, he summarises.

Hosur will focus on hydraulic cylinders and water jetting business. Apart from gearing up on the manufacturing front, we will also be expanding our dealer network to support the aftermarket demand of spares as well as sub-assemblies for new vehicle building”, points out Mr. Garud. “Our re-organisation is taking into account, all these factors so that our business strategy of increasing the market size and share along with the building of a robust aftermarket segment to the current OEM business will keep the organisation on a healthy growth path even in these testing times”, he summarises.

Water Jetting Business

IP Group has a strong presence in this line through reputed global companies like Pratissoli Italy, Hammelmann Germany General Pumps and NLB in USA. Each of these has a sales turnover of approx. over 80 million euros and IPH India currently is channelling these products to end customer and supporting the sales through service and supply of spares. “Currently we do about Rs. 50 million through the trading activity. We have only skimmed the surface in this potential segment and would like to take this as one of the thrust areas for future and expect to do a considerable business within a short period”, indicates Mr. Garud.

IP Group has a strong presence in this line through reputed global companies like Pratissoli Italy, Hammelmann Germany General Pumps and NLB in USA. Each of these has a sales turnover of approx. over 80 million euros and IPH India currently is channelling these products to end customer and supporting the sales through service and supply of spares. “Currently we do about Rs. 50 million through the trading activity. We have only skimmed the surface in this potential segment and would like to take this as one of the thrust areas for future and expect to do a considerable business within a short period”, indicates Mr. Garud.

Mr. Pavan, Vice President and Head-Design & New Product Development, says: “Along  with the high pressure water pumps, split shaft PTOs are supplied for transmitting the truck engine power to the end loads and propeller shaft The popular one for truck engine power rating up to 160 HP is the 400 Kgm split shaft PTO model that is used in Sewer cleaning machines. Pratissoli pump is supplied essentially for truck applications and the PZB (PZB is a brand of IPH company) split shaft PTO & Pratissoli High pressure pump (HP pump-reciprocating plunger type) combination has become the benchmark for municipal sewer jetting applications”. The company also intends to introduce 1200 Kgm split shaft PTO as an intermediate choice for certain special applications. “We can supply PTOs starting from 40 Nm rating (for SCV applications) to 3000 Kgm at the higher end. We intend to indigenize lower rated split shaft PTO’s but would continue to import the higher end models for some more time as the technology involved in the manufacturing at this juncture is advanced and complex”, adds Mr. Pavan.

with the high pressure water pumps, split shaft PTOs are supplied for transmitting the truck engine power to the end loads and propeller shaft The popular one for truck engine power rating up to 160 HP is the 400 Kgm split shaft PTO model that is used in Sewer cleaning machines. Pratissoli pump is supplied essentially for truck applications and the PZB (PZB is a brand of IPH company) split shaft PTO & Pratissoli High pressure pump (HP pump-reciprocating plunger type) combination has become the benchmark for municipal sewer jetting applications”. The company also intends to introduce 1200 Kgm split shaft PTO as an intermediate choice for certain special applications. “We can supply PTOs starting from 40 Nm rating (for SCV applications) to 3000 Kgm at the higher end. We intend to indigenize lower rated split shaft PTO’s but would continue to import the higher end models for some more time as the technology involved in the manufacturing at this juncture is advanced and complex”, adds Mr. Pavan.

Hammelmann makes engineered systems for essentially for the higher end industrial/special applications like ship hull cleaning, descaling, metal cutting, etc. These pumps are built to handle a maximum pressure of up to 3000 bar. IPH India sees good business prospects for the HP Pumps of both Hammelmann & Pratissoli makes vis-à-vis the industrial and mobile application sectors in the years to come.

Product Development

IPH India has been identified as a one of the global engineering centres for IPH products. Mr. Pavan explains, “We are concentrating on the concept of collaborative design, taking into perspective, the region specific requirements. Basic concept design comes from IPH Italy and we do in our centre the detailed engineering, prototype development, and the final product for the commercial application, and will continue to manufacture the product and export it for the global markets if required. Unlike many other companies which stop with the detailed engineering work, we take it through the other steps in the manufacturing cycle and bring out the final product for the market.” Mr. Garud points out that the need for such an approach has been to bring down the development costs which are invariably on the higher side in Europe, and leverage the ready availability of technical talent with price factor advantages to supply the products for world markets which demand competitive prices.

IPH India has been identified as a one of the global engineering centres for IPH products. Mr. Pavan explains, “We are concentrating on the concept of collaborative design, taking into perspective, the region specific requirements. Basic concept design comes from IPH Italy and we do in our centre the detailed engineering, prototype development, and the final product for the commercial application, and will continue to manufacture the product and export it for the global markets if required. Unlike many other companies which stop with the detailed engineering work, we take it through the other steps in the manufacturing cycle and bring out the final product for the market.” Mr. Garud points out that the need for such an approach has been to bring down the development costs which are invariably on the higher side in Europe, and leverage the ready availability of technical talent with price factor advantages to supply the products for world markets which demand competitive prices.

When questioned about the USPs of IPH products and how they address the competition from both local and international players in the field, Mr. Garud says: “Firstly it’s the quality. Each and every component we manufacture undergoes stringent quality control measures to ensure high standards of product quality. Another significant part of IPH’s technology up-gradation drive has been the use of high end state of the art computers to assist the latest machining centres the company has invested in. The quality and consistency of the products produced from such high standard set-ups are by far the best in its class and competing with world standards. By setting clear goals and operating parameters, we have been able to put the right systems and processes in place which are delivering phenomenal results. The other factors include ready availability of service support, spares and products for any of the truck applications at competitive rates”.

When questioned about the USPs of IPH products and how they address the competition from both local and international players in the field, Mr. Garud says: “Firstly it’s the quality. Each and every component we manufacture undergoes stringent quality control measures to ensure high standards of product quality. Another significant part of IPH’s technology up-gradation drive has been the use of high end state of the art computers to assist the latest machining centres the company has invested in. The quality and consistency of the products produced from such high standard set-ups are by far the best in its class and competing with world standards. By setting clear goals and operating parameters, we have been able to put the right systems and processes in place which are delivering phenomenal results. The other factors include ready availability of service support, spares and products for any of the truck applications at competitive rates”.

On the aspect of value creation he explains: “Whatever we do, we create ‘value’. At IPH we strive to create value by enhancing our equipment productivity and setting benchmarks in safety standards. Quality at IPH echoes in advanced technology products as well as world class customer care. Safety is an integral part of all our products, processes and services.” Mr. Pavan adds: “Also a key contributing factor to the consistent growth and strong performance over the years has been its focus on R&D and innovation. It offers great value to its customers through innovation and continuous research in enhancing product performance. The products are designed and manufactured to meet the exact requirements of the customers keeping in view of the aftermarket as well”. A few more important factors definitely have been the technical and financial support provided by the holding company at various stages during the Indian company’s evolution. Mr. Paolo Cleopatra, Chairman, IPH India and Vice President & CEO, IPH Italy, is well conversant with the Indian business conditions and is aware of the market ground realities. His understanding and encouragement together with vetting of business plans by IPH board have helped the company immensely in the expansion endeavor, indicates Mr. Garud.

IPH India has well laid out plans for addressing the anticipated market demands, and growing at more than 25% each year despite tough market conditions, the team at IPH is confident of better performance in the years to come. It has been more than six years in the making and today IPH India has established a strong foundation with the right strategies for the Indian market. Many of the products are already being supplied for worldwide markets and in addition to the same, India facilities could soon become the manufacturing base for the SE Asian market. With advanced technology supported products and solutions and not to forget the expansion drive undertaken, IPH India is gearing up to be the country’s largest pump and PTO provider in the coming decade. Well going by the track record, supportive principal, vibrant and committed workforce and clear marketing strategies, we should see IPH India soon achieve its goal and make a strong statement in the international arena as an important player of the IPH Group worldwide companies.