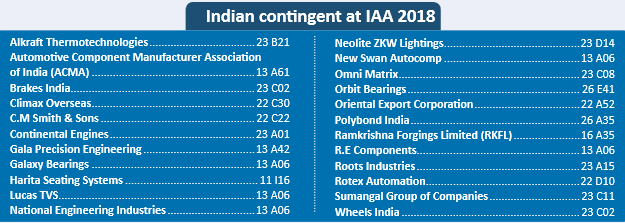

23 brands to showcase products & solutions at IAA 2018

IAA Commercial Vehicles, held every alternate year at Hannover in Germany, is the largest and most anticipated trade fair for the commercial vehicle segment globally. If one is looking for a platform where the latest technologies & solutions and futuristic innovations are premiered to the world, IAA would be the unanimous choice.

The 67th edition of IAA, to be held during September 20-27 at Hanover, will see global truck & bus majors, the very best among component suppliers, technology providers, truck application builders and a number of other stakeholders associated with the global CV industry demonstrate their capabilities to CV enthusiasts from around the globe.

Indian suppliers are known for long for their frugal engineering and have carved a niche for themselves when it comes to coming up with path-breaking, out-of-the-box and innovative solutions. Part of this could be attributed to the kind of challenging conditions in which vehicles run on Indian roads, but due credit has to be given for the suppliers who keep churning out amazing, globally-accepted solutions.

Now, with the Indian CV market maturing faster than ever in terms of performance, safety, fuel efficiency, comfort and connectivity, Indian suppliers are making the most of the opportunity available and naturally are trying to make it big in the global arena.

India will have its strongest representation at the forthcoming IAA through 23 brands which would be vying to grab the limelight at the most important stage of the global commercial vehicle industry. We take a look at what some of them have in store for the fair and what they think about the growing global ambition of home-grown suppliers.

Brakes India

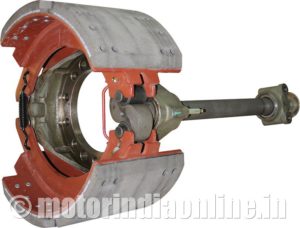

Brakes India, a joint venture between the TVS Group of India and ZF of Germany, is the largest player for commercial vehicle brakes in the Indian market. The company’s product portfolio for CVs includes S-cam, hydraulic drum brakes, air disk brakes and electromagnetic retarders.

Mr. Sriram Viji, Deputy Managing Director, Brakes India, reveals why the company is confident of making a mark at the world’s largest commercial vehicle trade fair and its plans for global markets.

Excerpts:

Main aim of exhibiting at IAA 2018

The Indian commercial vehicle market is advancing rapidly, both in terms of volumes and technology. With the entry of global OEMs and the shift in regulations towards global standards, we find greater similarity between the product specifications and the quality requirements in India and those at the global level. This enables us to leverage our existing capabilities on a more global scale.

Further, as more global OEMs set up production, design or sourcing offices in India, it also becomes relevant for us to ensure we reciprocate and showcase our willingness to support these customers globally.

IAA provides us a good opportunity to showcase our product and engineering capability to the overseas market.

Products to be showcased

Brakes India will be showcasing its range of pneumatic and hydraulic brake systems and hydraulic clutch products, including some products licensed from our technology partners like ZF and Meritor. The pneumatic foundation brake system display would include air actuated disc brakes and ‘S’-cam drum brakes, which service wheel rim sizes from 16” all the way to 25” and tonnages from 7 T to 49 T. The hydraulic braking system would have hydraulic disc and drum brakes, vacuum boosters, hydraulic uni-boosters and hydraulic anti-lock braking systems (ABS).

This will cater to vehicles from 4 T to 11 T with significant opportunities for light weight braking systems for these lower tonnages. Among the clutch actuation products, we will have the concentric slave cylinder, plastic master cylinder and a pneumatic clutch booster. Brake accessories such as pedal box assembly, hydraulic brake hose assemblies and transmission parking brake would also be showcased.

Company presence in overseas markets

Brakes India and its associated foundries are among the larger automotive component exporters in India. Together we export products worth over Rs. 800 crores globally, and this has been growing in pace with our overall growth.

On the commercial vehicle braking side, we have designed and developed brake systems for OEMs based in Europe and Japan. We have been supplying brakes in the export market for over 10 years. The products are recognized for their quality and supply consistency. We also support our technology partner Meritor by manufacturing air disc brake assemblies and sub-assemblies for the global market. We are also in discussion with our existing customers to increase the scope of supply and also with new OEMs to supply similar products.

Our foundry has been a long-term supplier of critical commercial vehicle castings for chassis and engine applications, such as mounting brackets, bearing caps, anchorages, disc brake castings, turbocharger housings and manifolds, etc. The foundry has been recognized for quality as well as for the green foundry practices. In this area, we are diversifying into larger castings and more specialized materials such as high-strength, high-temperature and heat-treated iron castings.

Indian suppliers’ growing global ambitions

There are many factors that help open up the global market for players in India. The growth and the scale of the Indian market is one factor which, for example, has enabled Brakes India to become one of the largest manufacturers of commercial vehicle brakes in the world. As mentioned earlier, the common regulations also enable products to be more uniform globally. However, there are still many differences, such as the rate of adoption of newer technologies, the importance of light weighting, the duty conditions experienced in different markets, etc. It requires a strong focus on engineering and development to bridge these factors.

Brakes India’s focus on these areas for the past decades, backed up by our quality and delivery performance, has helped us serve global customers in a seamless manner.

Alkraft Thermotechnologies

Alkraft Thermotechnologies is a pioneer in aluminium engine cooling systems and one of the largest manufacturers of brazed aluminium radiators, oil coolers, charge air coolers, and cooling system modules in the Indian market. The company has its strong presence in a number of verticals, including OEM and aftermarket automotive, industrial equipment, tractors & agricultural equipment, and power generation equipment.

Mr. Basil Siddeeqi, Director, Alkraft Thermotechnologies, takes us through his company’s plans for its IAA debut and its growing global aspirations.

Excerpts:

Main aim of exhibiting at IAA 2018

Firstly, Indian ingenuity and expertise must play a greater role on the global manufacturing stage. Being a leading provider of thermal management solutions to the Indian commercial vehicle industry, we have developed and built products that have set benchmarks for efficiency and performance in our highly demanding market. The Indian conditions for CVs are characterised by extreme ambient temperatures, dusty environments, rough roads, and product abuse. We have successfully overcome challenges in these conditions and have consistently built precision-engineered products with the best reliability, durability, and performance-to-weight ratio for the value conscious OEM customers.

A defining characteristic of Alkraft since our founding has been our willingness to challenge the status quo and reimagine possibilities to address new challenges. This attitude, together with our expertise in building products for tough and diverse conditions, will enable us to offer great value to global customers. As an Indian manufacturer, this is what we intend to showcase at IAA 2018.

Products to be showcased

We are displaying a 250 hp Euro-6 compliant engine cooling module along with some other high performance heat exchangers. While these products are testament to our technological superiority, they do not truly represent the range or scope of our expertise which is much broader.

Company’s presence in overseas markets

Ever since our inception, we have been primarily focused on developing products tailored for the Indian market, due to which exports stand at only about 5% of our total revenue. The CV, industrial and defence product segments in Russia, the Middle East and North America have been our traditional export markets, but we understand that the scope and opportunity for a product like ours is much greater in terms of both application and geography. We aim to increase our share of exports to 20% over the next three years.

Indian suppliers’ growing global ambitions

The Government’s ‘Make in India’ programme and export-focused initiatives are motivating many Indian manufacturers to go global, and we are concentrating our efforts for an intensive global push as well. More representation by Indian companies, particularly those with proprietary technologies like ours, at global events is a great sign. We are aware of our responsibility, and hope to be worthy ambassadors of Indian industry at these global events.

Rotex Automation

Rotex is a prominent manufacturer and exporter of fluid control systems, pneumatic actuators, valve automation systems and control components, with market presence in more than 30 countries.

Mr. Vilas Balang, Head – Business Development (Automotive, Aero-space and Defence), Rotex Automation Ltd., shares his expectations from IAA 2018 and what his company has in store for the show.

Excerpts:

Main aim of exhibiting at IAA 2018

IAA Commercial Vehicles is a global exhibition that we make sure not to miss. Our main aim is to showcase our wide range of solenoid valves and modules. The fair is one of the most important platforms for Rotex to meet our customer base and create opportunities with new customers for future growth.

Products to be showcased

We will be showcasing a wide range of solenoid valves and fluid control modules for emission aftertreatment system, tipping and transmission systems, engines & fuel system, thermal management/HVAC system and suspension/air management system. We are a global leader for auto drain/water management of fuel-water separator and this will be the highlight of our booth. Besides, our solution for air suspension and transmission system are expected to catch the attention of visitors at the upcoming exhibition.

Company presence in overseas markets

For more than six years, we have been exporting much more than our business in the domestic market. Today 80% of our revenue comes from exports to the European and North American markets. Over a period of the next five years we are poised to bring exports to 50% by implementing the export product lines in the Indian market. Today a majority of our products are for the aftertreatment system, and as India is gearing up for BS-VI we are poised to be a huge beneficiary in future.

Indian suppliers’ growing global ambitions

These are exciting times in India as there is significant growth in the CV market. Component suppliers are investing in capacities and also breaking into new markets. In our case, as mentioned earlier, markets like Europe and North America have always been very important for us and contribute a lot more than our domestic sales as of now. However, we have several programs for the domestic market which will change the scenario in the near future. We are a unique company as we have traditionally competed with the best in the world. We are now implementing our learnings to technologies that are currently evolving in India.

Wheels India

Wheels India, part of the TVS Group and India’s largest manufacturer of wheels for different vehicle segments, is making its debut at IAA this year. We find out from Mr. Srivats Ram, Managing Director, Wheels India, about the company plans for its first participation at the world’s largest CV fair.

Excerpts:

Main aim of exhibiting at IAA 2018

Wheels India is participating in the IAA Commercial Vehicles 2018 show to showcase our current and new generation of steel and aluminium wheels for trucks, buses and other commercial vehicles, leveraging our R&D capability. We would like to engage our strategic customers in Europe and look at opportunities to develop new relationships in the region.

Products to be showcased

We are showcasing a broad range of steel and forged aluminium wheels for trucks and buses, lift-axle suspensions and Tire Pressure Monitoring Systems (TPMS). We are also showcasing a defence wheel for a commercial vehicle platform.

Company’s presence in overseas markets

We, as a company, have always looked at leveraging business relationships across geographies and products. Currently close to 20 per cent of our sales revenues comes from exports. In relation to the IAA, we export steel and forged aluminium wheels to customers globally. Additionally, Wheels India is already part of the global supply chain for construction and agricultural equipment manufacturers. Our major markets for export are Europe, USA, Japan, Korea, Brazil, Mexico, and other countries in South-East Asia and South America.

Indian suppliers’ growing global ambitions

The Indian auto component industry has been able to develop world-class manufacturing and product quality by engaging with global companies present in India. This, combined with increasing R&D capabilities, opens up new markets for suppliers. Wheels India has been focusing largely on benchmarking international products and ensuring we meet the highest quality standards. Our relentless focus on R&D allows us to improve design, simulation and validation in the field using state-of-the-art telemetry to capture data and improve wheel performance.

Ramkrishna Forgings (RKFL)

Kolkata-based Ramkrishna Forgings Ltd. (RKFL) is a flagship supplier of forged and ring-rolled products for the front and rear axles, engine and transmission systems, among others, to all major commercial vehicle OEMs or tier-I firms across the globe. The company is making its second participation at IAA this year.

Mr. Milesh Gandhi, Vice President- Marketing & Sales, RKFL, reveals details of the company’s clear-cut vision and strategy to become a globally-acclaimed supplier and put India firmly on the global supplier map.

Excerpts:

Main aim of exhibiting at IAA 2018

IAA Commercial Vehicles 2018 gives us the perfect platform to showcase our engineering and manufacturing strength to the global OEM & tier-1 fraternity. The global CV market is already going great guns. With favorable macro-economic environment foreseen, volumes are expected to touch unprecedented highs. A congregation of OEMs of this nature not only gives us the distinct advantage in our endeavor to expand our footprints worldwide, it also helps the OEMs to identify potential partners from across the globe who would be able to maintain the stringent quality norms while providing certain strategic benefits in terms of cost and availability. It is the initiation of such mutually synergistic alliances that we hope to forge at this years’ IAA.

Products to be showcased

As an organization specializing in manufacturing components for the automotive sector, it is imperative that we differentiate ourselves from an engineering capability point of view from our competitors. With this sole aim, we would be exhibiting safety critical front axle components – front axle beams, knuckles, real axle components – crown wheel, pinion, diff cases besides others. Showcasing a wide array of such products gives the global community an insight into our state-of-the-art manufacturing facilities and the vast technical know-how we possess besides providing a distinct advantage to our valued customers.

Company’s presence in overseas markets

At present, RKFL has five production facilities, and is adding two more facilities, that extend our annual capacity of forgings close to 220,000. It is spreading its wings internationally with dedicated offices and warehouses set up in the US, Mexico, Germany, Netherlands and Turkey. Exports account for over 30 percent of our revenue. Technology being a prime driver for this industry, with enhanced forging press techniques and equipment opening new avenues across the time, our revenue is Euro 200 million and we are aiming to become a Euro 500 million company by 2023, with a clear vision to be the most prepared forging supplier for any OEM & tier -1 related to the CV industry globally. We are currently supplying our products to the US, Mexico, Brazil & other parts of South America, Germany, Sweden, Netherlands, Italy, Spain, Belgium and Turkey in Europe, Bangladesh & Thailand in Asia and Australia. We will soon be starting supplies to Japan as well.

Indian suppliers’ growing global ambitions

Emerging markets are all moving toward a knowledge-based economy which is where the future lies in the 21st century. Quality has taken precedence over cost which is why there are ample examples of organizations investing in manufacturing in India. With cost of production still lower in emerging markets as compared to the western world and international certification bodies recognizing the quality available in India – manpower, manufacturing process and facilities – there is no reason why Indian suppliers should hold themselves back. At the other end of the spectrum, global OEMs are now much more confident in sourcing parts from India – it is this need from both ends that is driving this development.

This is our second participation in the IAA. In the 2016 edition where 2,000 exhibitors from 52 countries were present, we were proud to represent India with a massive presence which was the biggest amongst the 30-odd Indian companies that participated in the fair. We are sure that such participation will give a big impression for India in the global arena.

C.M. Smith & Sons

C.M. Smith & Sons, a leading producer of Grey Cast Iron and Nodular Iron (Ductile Iron) castings from 5 kg to 150 kg in a single piece, has been supplying fully-finished parts to OEMs for over six decades. The company mainly produces parts for engine, axle, transmission, chassis, etc., and caters to various sectors, including automotive, agricultural, construction, railway, off-road, tractor, hydraulic, pumps and valves.

Mr. Bikash Singhi, GM – Sales & Marketing, C.M. Smith & Sons Ltd., tells us about his company’s participation at IAA 2018.

Excerpts:

Our main aim at IAA Commercial Vehicles 2018 is to generate export orders. With our focus on identifying new customers in the CV segment, we will be showcasing our range of axle and transmission components.

Company’s presence in overseas markets

Currently our exports account for nearly 10% of our total sales, but we have a target to go up to 25% in the next two years. Our key export markets are North America and Europe. We are also in the process of bagging orders from Japan customers in the market.

Our domestic market is very robust and dynamic. Having said that, to mitigate the risks of our domestic business we ought to have at least 30 per cent sales from export markets. In India, we are supplying parts to all leading global OEMs like Daimler and Volvo. We feel leading Indian suppliers are well aware of the overseas requirements and are fully capable of fulfilling them.