Clean and promising?

At Hannover Messe 2022 expo, Germany-based EVS Hydrogen presented its latest state-of-the-art hydrogen combustion engine as a direct and practical replacement to diesel engine technology in construction equipment and off-highway applications. With hydrogen fuel cell and battery-electric technologies facing significant bottlenecks to crack this demanding space, can hydrogen combustion technology be a game-changer to clean the off-highway segments? Dhiyanesh Ravichandran reports.

Across the globe, heavy-duty and off-highway motor applications including construction machinery are coming under stringent emission regulations. However, the penetration of clean and alternative energy technologies are extremely limited in this space, despite considerable evolution of such technologies in recent times, proven by the emerging battery-electric mobility segment and hydrogen fuel-cell system for commercial vehicles.

Whatever clean energy solutions that are available for off-highway applications at present, may it be natural gas, battery-electric, or hydrogen fuel-cell systems for select class of machines like forklifts or backhoe loaders, are considered as mere ‘interim’ options by the end users, only for the time-being, until a much more potent and reliable technology emerges for large-scale commercial use-case scenarios.

The bottleneck lies in the fact that the off-highway is a ‘niche’ segment in all sense, that its operational parameters and commercial economics are very different from that of passenger mobility or commercial haulage. Further, the automotive industry’s current approach towards quicker transition to electric drive technologies is not in sync with off-highway’s approach to sustainability. Emission or fuel type is not the sole criteria for cleaner operations here, but long-term efficiency, practicality, and affordability for 24/7 operations anywhere, anytime also matters a lot.

The consensus in the off-highway circles is that there is a pressing need for a viable solution, which matches with the existing applications in utility and practicality parameters, while also facilitating the transition to a new fuel technology through simplicity and affinity. Because, the schematic design and engineering of the hydraulic machines cannot be redesigned drastically for alternative powertrains, nor the charging infrastructure be made available in each and every remote and tricky locations where these machines are deployed.

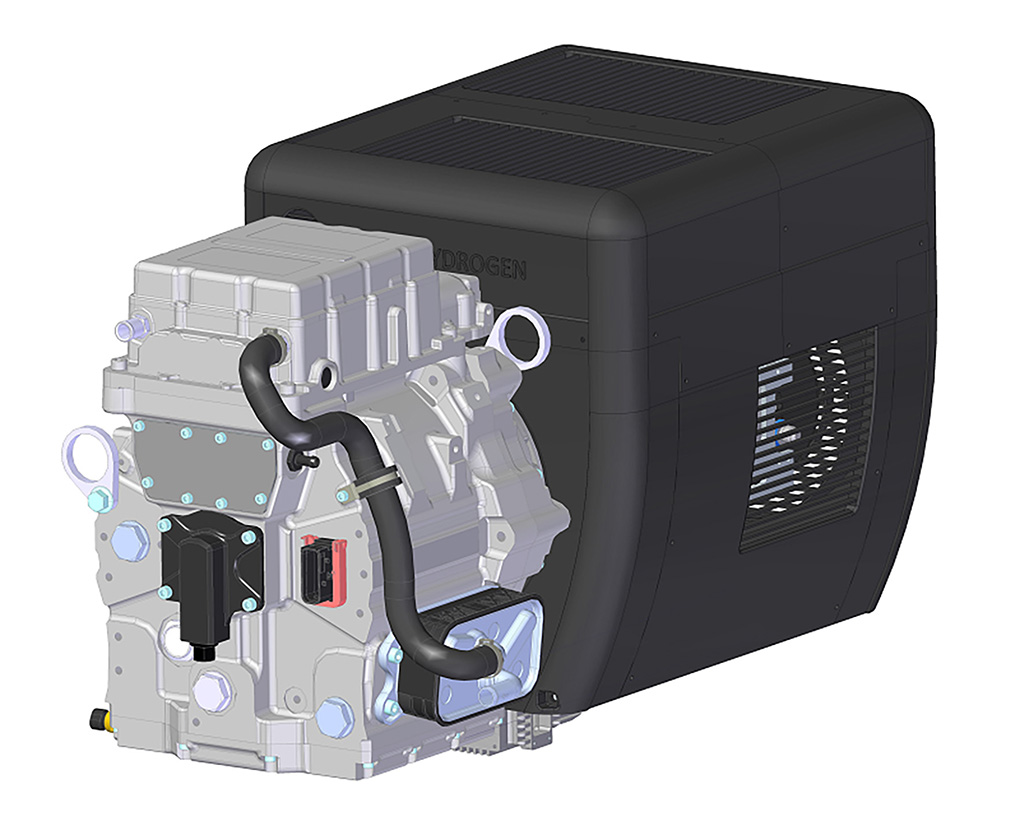

German firm EVS Hydrogen claims to rightly address this ‘niche’ scenario. The company is into the field of developing new engine technology with immense experience in design and manufacturing of mechanics, electronics, and related software. What it claims to have succeeded is developing an emission-free industrial propulsion technology, similar to existing technologies used in heavy-duty applications, but relying on a sustainable fuel – the hydrogen (H2). It presented its advanced hydrogen combustion engine at the recently held Hannover Messe 2022, kindling debates among industry experts on the relevance of this technology in today’s contexts.

The concept isn’t anything new here. The hydrogen combustion technology is essentially the good old internal combustion engine (ICE) designed to run on H2 in place of diesel. Whereas the fuel cell technology in FCEVs involves a much complex system with minutely-engineered fuel cells that convert H2 (chemical energy) into electrical energy, which in turn power battery packs and electric motors of the vehicle. But the catch here is that FCEVs emit no emission besides water vapour as by-product of the chemical process, but the hydrogen engines generate oxides of nitrogen (NOx), although no trace of CO2 and particulate matter are present its emissions.

Thus, the apprehension with the H2 combustion engines is quite apparent. Many see the technology as a step back from the zero-emission pursuit, and may even harm any little progress made towards electric or fuel cell mobility in heavy-duty segments. H2 engines are also dismissed as less efficient and costly to run and maintain, as there are multiple mechanical and child parts involved in the powertrain. H2 as a fuel is also not widely available, which means a similar parallel infrastructure may be required, a problem also shared by battery-electrics. But there is more to the story.

EVS Hydrogen claims that its H2 engine is very similar to existing diesel engines in terms of design and operation, which means it can be fully integrated into existing vehicle design and drive systems. In off-highway machinery, the rotating mechanics for hydraulic systems is the heart and soul. This has been a biggest impediment to direct replacement of conventional drivelines with fuel-cell or battery systems, as space constraints come into picture. This makes the H2 engines ideal for construction equipment, as they come with a rotary motor. This extends an important advantage of torque-controlled operation similar to diesel engine.

The H2 engine also incorporates a hybrid design, wherein electric motors and combustion engine form a single unit to enable modern electrified applications wherever desirable. EVS Hydrogen says that the engine features direct injection with low-pressure technology and special combustion process, which makes it more efficient and economical to run for longer hours. The engine’s robustness to fuel quality enables it to run on different grades of H2, as the fuel quality is dependent on manufacturing processes and materials today. Standardization of H2 may take time, which in fact is making FCEVs less desirable at present.

Further, the H2 engines can operate in rugged and dusty environments, and engine overhauling can be simpler unlike fuel-cell or electric powertrains. Thus, from an operator’s point of view, the switch to hydrogen engines is less risky, more reliable, economically affordable, and practical. On the emissions front, companies including JCB and Cummins are of the opinion that these engines have similar emission profile as fuel cell systems. Given that the transition to H2 engines can be easier and achievable in short-term, the benefits out of the reduced total emission weighs more than its actual emissions.

EVS Hydrogen opines that the construction machinery and off-highway segments have to make a quicker transition towards sustainability to address the climate protection goals set for the industry. With independence of charging infrastructures and costly electronics involved in electric and fuel-cell technologies, the H2 combustion engine represents a sensible solution, not just for construction equipment and off-highway machinery, but even for municipal applications like parcel delivery services and waste disposal systems in urban areas.

This concept certainly puts an interesting spin on things. H2 engines in machines are just around the corner. Construction equipment maker JCB is already taking the lead, which recently unveiled the world’s first digger powered by a hydrogen combustion engine. But we may have to wait and watch how the market shapes in the coming years, especially in developing countries like India where the demand for sustainable solutions in CE and off-highway space is yet to start.

-Dhiyanesh Ravichandran