In a tête-à-tête with Mr. Sukhmander Gill, Managing Director, Gobind Body Builders, who proudly states: “We are Indians and we rely only on Indian technology”.

Gobind Body Builders hardly needs an introduction today. While we all are familiar with the sleek, contemporary designs that the brand has now become synonymous with, very few are aware of the humble beginning that Gobind’s origins can be traced to.

“It literally was a very humble beginning, about 40 years ago. We were originally an operator, with a fleet of buses. Back in the day, Punjab wasn’t home to as many bus body builders as it is now. So once, when one of our buses needed an overhaul, my father, now the acting Chairman of the company, Sardar Darshan Singh rolled up his sleeves and took the entire project repairing the bus body on himself; that’s how it all started,” reminisces Mr. Gill.

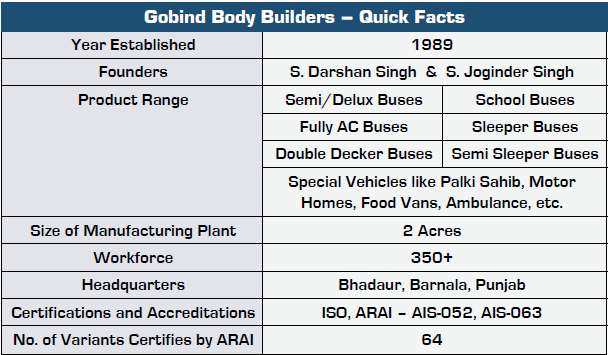

Unknown to them, the project soon proved to the harbinger of a new beginning. The finished product was received with immense approbation and soon, requests from neighboring started pouring in. As the body repairing reputation started to spread, Sardar Darshan Singh, realizing the prospect, formally set up Gobind Body Builders in 1989 along with his brother S. Joginder Singh.

Technical Prowess

Today, the company’s manufacturing plant in Bhadaur, Barnala sprawls across an area of 3 acres and is manned by a workforce of more than 350 human resources. About 300 manual workers work under the supervision of the various departments like R&D, Design and QA to shell out one vehicle per day from the plant.

“We work on about 70-73 buses at a go and the aim is to deliver one order every single day. For non-AC seaters we take about 45 days to complete and for AC seaters, the turnaround time is about 60 days. Sleeper buses take a little longer – about 70-75 days, because it demands an immense detailing and attention to details,” Mr. Gill avers.

It goes without saying that technology is the backbone of a successful business, now more than ever. Gobind comprehends this and has armed itself with a string of newfangled machinery and technology. “We have the best in the market range of shearing, moulding, bending and CNC machines along with punch systems that feature individual fixtures,” he adds.

On being asked if they bank on imported technology, Mr. Gill proudly states, ‘Hum Indian hai aur Indian machines hi use karenge (We are Indians and we rely only on Indian technology)’ – a fine example of the Make in India movement initiated by the NDA Government in 2014.

The R&D and Design departments of the company employ about 30 experts combined, to produce what has now become the hallmark of Gobind Body Builders – chic and contemporary bus body designs.

Gobind’s designing system is fully automated – all designs are executed in Dassault Systèmes’ 3D CAD design and analysis software SolidWorks. The designs are then fed into CNC machined that creates fiber moulds and composites with precision. But in rare occasions when certain projects succeed in piquing the Sardar Darshan Singh’s interest, he personally mans to them with an old school twist. “He is very enthusiastic about work and sometimes some projects really interest him. In such projects, he drafts the design himself, which are then rendered via SolidWorks,” reveals the MD.

The North-East Connection

As if embossing marks of unmatched excellence in a market as competitive as Punjab wasn’t a fete in itself, Gobind’s popularity in the North East region of India is another feather in its cap. For the uninitiated, let me reveal to you all that Gobind Body Builders is one of the most sought-after names in the bus industry in the north eastern States of India, especially Assam. We asked about the connection.

“Assam, and most of the northeast region for that matter, is marred my deplorable road conditions. So, for one, bodies of buses plying have to be extra robust. Secondly, the north eastern consumer is very aware, informed and demanding – they want only the best in services, amenities and sometimes even visual appeal. Our ARAI approved raw materials and stringent quality analysis module assure operators of the strength and our designing team ensures that customer’s demand for aesthetics are duly met. It’s a win-win proposition for both, so it works naturally,” expresses Mr. Gill contently.

The Branding Proposition

“When the next generation of the family joined the business, we started steering it to evolve and be at par with modern times. Our marketing motto is maintaining a close communication with the customer throughout the development process,” he states.

At Gobind Body Builders, clients are welcomed to personally monitor the progress of their vehicles. Clients are invited to visit the manufacturing plant as frequently as they want and keep a check of the quality and progress themselves. While it might seem like a risky proposition to many, it has, if Mr. Gill is to be believed, ushered in a positive impact that has been instrumental in bolstering brand recall. “Today, it’s more about experience than purchases – across all industrial segments. We endeavor to give our customers an experience along with a great product. It has definitely contributed to building a good brand recall,” he says. “Moreover, the first preference is always given to the drivers’ suggestions and requirements, because it’s them who spend the most time with the vehicle and nobody knows better than them,” he adds.

Market Presence and Future Plans

Gobind Body Builders enjoy a pan India presence, with the core market constituting the states of Punjab, Haryana, Rajasthan, Maharashtra, Assam, J&K, Karnataka, Delhi, Uttar Pradesh, Uttarakhand, Himachal Pradesh and Gujarat. The company has also debut exports to Nepal recently.

“Nepal has stringent laws pertinent to the number of buses per area, so as of now, we have only exported 20 buses. But the response we have received is overwhelming and we look forward to serving our neighbor soon,” he reveals.

The company has also revealed their aggressive plans of expansion. Although the MD refrained from giving out exact details, he gleefully disclosed the starting of a new production unit in the forthcoming months.

“When the next generation of the family joined the business, we started steering it to evolve and be at par with modern times. Our marketing motto is maintaining a close communication with the customer throughout the development process.” – Mr. Sukhmander Gill, MD, Gobind Body Builders

By Shivam Gautam