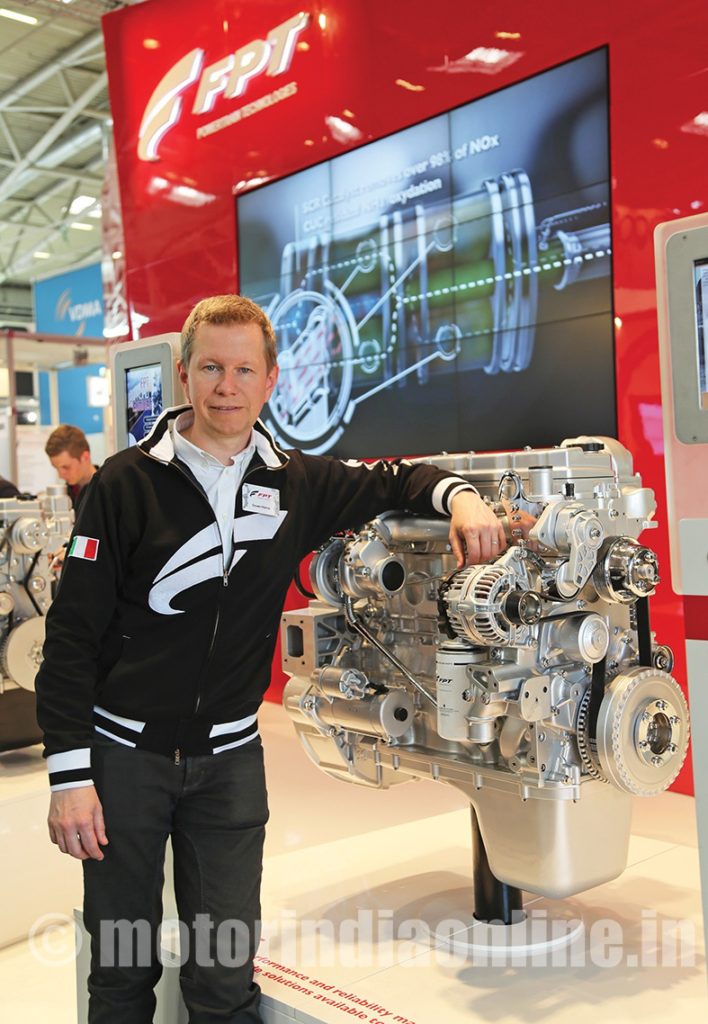

Alongside its comprehensive range of engines, FPT Industrial, the world-leading manufacturer and supplier, showcased its patented second generation HI-eSCR after-treatment stage V solution. The extensive range of off-the-shelf powertrain solutions for construction applications, from mini excavators to wheel loaders, covers from 2,2 to 20 liter and can meet all customer demand. If this is not enough FPT has the capability, with its 7 R&D centers and over 900 engineers around the world, to develop customized products, matching even the most demanding request from OEMs.

To comply with Stage V emission standards, all engines above 4 liters will use HI-eSCR2, the second generation of the FPT Industrial’s renowned and patented High Efficiency Selective Catalytic Reduction (HI-eSCR) after-treatment technology.

FPT Industrial confirms its long-term SCR-only strategy in order to achieve uprated standards. It’s one of the few manufacturers to retain an Exhaust Gas Recirculation (EGR) and active regeneration free solution, maintaining the competitive advantages achieved in Stage IV/Tier 4B, such as best in class in fuel economy and best in class in power and torque density.

In order to meet Stage V both particle mass and particle count requirements, the second generation HI-eSCR system has an integrated particle filter on the SCR, which makes it an extremely compact solution. When considering the engine, its cooling and after-treatment system FPT’s solution is 10 per cent smaller than the competitor average (considering 6 liter, 6 cylinder engine competitors).

On top of this, FPT’s flexible solution, with up to 20 different layouts available for each power node, avoids additional redesign efforts from the vehicle manufacturer, as its predecessor. The newly-integrated particle filter does not require active regeneration, and the engine is best in class in fluid consumption, using around three per cent less vs. competitor average using EGR and with active regeneration.

FPT Industrial is a brand of CNH Industrial, dedicated to the design, production and sale of powertrains for on and off-road vehicles, marine and power generation applications. The company employs approximately 8,200 people worldwide, in 10 manufacturing plants and seven R&D centers. Its industrial sales network has 90 dealers and over 1,000 service centres in almost 100 countries. A wide product offering, including six engine ranges from 31 kW up to 740 kW and transmissions with maximum torque of 200 Nm up to 500 Nm, and a close focus on R&D activities make the company a world leader in industrial powertrains.