Carrier Transicold has built an exclusive e-Solutions Lab in its stand at the IAA Show in Hanover and is inviting customers to step inside for a glimpse at what a world with ‘connected refrigeration’ might look like. Carrier Transicold is a part of UTC Climate, Controls & Security, a unit of United Technologies Corp.

Inside the lab, visitors can experience many of the technologies being considered for future generations of Carrier Transicold refrigeration systems, from advanced real-time communication to assets that proactively transmit notifications to the customer. Connected refrigeration is expected to support complete traceability within the cold chain, from farm to fork, as well as sustain efforts to monitor and reduce environmental impact.

Also on display in Hall 27, on the Rohr stand, is the first prototype Carrier Transicold natural refrigerant trailer unit to be delivered to a customer in mainland Europe, which will enter service with Netto Marken-Discount following the IAA Show under a three-year technology field trial. The trailer unit, delivered by Carrier Transicold Germany, has already been recognised as winner of the environment category in the prestigious Trailer Innovation Awards 2017, which will be formally presented at the IAA.

The unit marks a new generation of Carrier Transicold transport refrigeration systems for trailers that operate exclusively with carbon dioxide (CO2) refrigerant in a closed-loop system. CO2 is a safe and non-ozone depleting gas with a global warming potential of one, making it the baseline against which all other refrigerants are measured.

In addition, visitors can see a new generation of engineless transport refrigeration technology, following Carrier’s acquisition of TRS Transportkoeling b.v. (TRS). A TRS ECO-DRIVE GenSet unit is featured prominently in the Carrier stand, and also on a vehicle in the live demonstration area outside (N93). The display units showcase how hydro-electric power generated by a truck’s Euro 6 engine can be harnessed to cut emissions, maintenance costs and help to improve fuel efficiency.

Carrier Transicold is also showcasing its latest evaporator range for Supra® and Vector™ temperature controlled units, which offer a range of operational benefits. They can be quickly installed and dismounted to aid repair and maintenance. Completing the line-up in the stand are examples from the Supra®, Vector™ and Pulsor™ ranges.

Inside the lab, visitors can experience many of the technologies being considered for future generations of Carrier Transicold systems, which are expected to support the complete monitoring of products in the cold chain, from farm to fork, as well as sustain efforts to monitor and reduce the environmental impact of the refrigeration units. These technologies include advanced real-time communication systems to temperature-controlled systems, which can proactively transmit notifications, including temperature changes or fuel loss to the customer, for maximum cold chain visibility and protection.

“We have built the lab to provide an exclusive look at what a world with connected refrigeration units will look like. The lab is also an opportunity for dialogue with key stakeholders within the cold chain from across Europe – including fleet owners, engineers, drivers and consumers. We’ll be discussing what next-generation technologies will be, and exchanging views on what is considered essential, versus desirable. The conversation will help to shape our future steps, even considering what doesn’t yet exist in our industry” said Victor Calvo, Managing Director, Carrier Transicold Truck & Trailer, EMEAR.

To demonstrate how connected refrigeration can work, visitors to the Carrier Transicold stand are being invited to scan QR codes on apples distributed at the stand. Once scanned, visitors will have full access to information about the apple they select, tracked along the cold chain from farm to fork, an insight into how connected refrigeration of the future could work.

German retailer Netto Marken-Discount will become the first customer in mainland Europe to take delivery of Carrier Transicold’s prototype natural refrigerant trailer unit. The system, winner of the environment category in the prestigious Trailer Innovation Awards 2017, is featured on a new trailer, which is being displayed in the Rohr stand in Hall 27 stand F09 and will enter service with the customer following the IAA Show. The unit was delivered to Netto by Carrier Transicold Germany, a part of UTC Climate, Controls & Security, a unit of United Technologies Corp.

The Trailer Innovation Awards are held bi-annually to encourage innovation in the trailer and bodybuilding industries. The prestigious awards are judged by editors from 14 major commercial vehicle trade publications across Europe, with the environment category award and presented to Carrier Transicold at the IAA Show. The award follows less than a year after Carrier Transicold won the innovation award for sustainability at the Solutrans trade fair in France, which recognised the company’s pioneering refrigerants strategy.

Netto Marken-Discount, which has one of the largest produce selections among discount stores in Germany, will be testing the unit in a three-year technology field trial.

The unit marks a new generation of Carrier Transicold transport refrigeration systems for trailers that operate exclusively with carbon dioxide (CO2) refrigerant in a closed-loop system. It uses advanced technology from Carrier Transicold’s NaturaLINE™ container refrigeration system, assembled inside a traditional Vector™ unit chassis and powered by the same patented E-Drive™ all-electric technology as the existing Vector range.

“Delivering this natural refrigerant trailer prototype into service marks another significant milestone in the development of over-the-road refrigeration using CO2. Our ultimate vision is to see temperature-controlled units running on natural refrigerant in mainstream production. Today, with the support of one of the largest German retailers in the food discount segment, we are another step closer” said David Appel, president, Carrier Transicold & Refrigeration Systems.

CO2 is a safe and non-ozone depleting gas with a global warming potential (GWP) of one, making it the baseline against which all other refrigerants are measured. The GWP of CO2 is also lower than other natural refrigerants, such as propane.

“When we heard that Carrier Transicold was developing a natural refrigerant CO2 trailer unit, we were eager to get involved. The delivery of this prototype is a huge step forward for the industry and we are excited about its potential for helping us to achieve our environmental and sustainability targets” said Christina Stylianou, Head of Corporate Communication, Netto Marken-Discount.

Netto Marken-Discount has taken a leading position in testing the new Carrier Transicold innovation in the first real-life trial in mainland Europe, with the trailer set to be used for regular store deliveries.

Carrier is also introducing visitors to a new generation of engineless transport refrigeration technology at the IAA Show, following its acquisition of TRS Transportkoeling b.v. (TRS) in January 2016.

Across Europe, Carrier Transicold now offers fleets refrigeration units running entirely on hydro-electric power generated by a truck’s ultra-clean Euro 6 engine, cutting emissions, maintenance costs and improving fuel efficiency. The TRS technology is also exceptionally quiet and fully PIEK certified, meaning it can operate below 60 decibels, which makes it ideal for night-time deliveries in urban areas.

The new technology is presented at the Carrier Transicold stand in Hall 27 with a TRS ECO-DRIVE GenSet unit, and in the live demonstration area at Carrier Transicold’s external stand (N93).

“The IAA Show represents the perfect opportunity to introduce both existing and prospective customers to the many benefits afforded by the new TRS technology, which now carries the Carrier Transicold brand and is supported by our service network,” said Mr. Victor Calvo.

“These units add a new dimension to our range of products and directly support our goal of helping fleet operators meet their efficiency and sustainability goals, and achieve a sustainable cold chain,” he added.

When mounted to a commercial vehicle, the TRS ECO-DRIVE GenSet is driven by a hydro pump connected to the truck’s power take-off (PTO) motor. The hydraulic system drives a generator that delivers electrical power to the host Carrier Transicold unit, without any requirement for the refrigeration unit to use its own diesel engine.

Integrated into the hydraulic system is a control unit that ensures the generator consistently runs the same number of revolutions. This maintains constant power, even when the truck is idling in heavy traffic, eliminating any need for the driver to rev the truck’s engine to provide sufficient cooling power.

ECO-DRIVE GenSets require little maintenance and are very quiet in operation. They can also be fitted to nearly all makes and models of tractor units and rigid trucks, giving them the widest possible customer appeal.

The acquisition of TRS has also given Carrier Transicold access to the former TRS range of transport refrigeration units, which now complement the full range of systems available from Carrier Transicold. The TRS systems stand out for including the powerful TWIN-COOL multi-temperature refrigeration unit for rigid trucks, with a power output of 18,400 watts to give it the equivalent power capacity of a high-output trailer unit.

The company is also showcasing its latest evaporator range for Supra® and Vector™ temperature-controlled units at the IAA Show. The new evaporators are displayed alongside models selected to highlight the breadth of the Carrier Transicold range, which includes systems for light commercial vehicles, rigid trucks and trailers.

The new evaporators are suitable for multi-temperature applications and feature new styling, with models available in four widths ranging from 700 mm to 2,200 mm. A new defrost operation and improved water drain eliminate the risk of water splashing onto the cargo being transported. Plus, they can be installed quickly and easily in both rigid bodies and trailers, with a fast dismounting system to aid repair and maintenance during a long life in service.

Supra® Truck Unit with Low Emissions Pack

Joining the new evaporators on display is the latest Supra transport refrigeration system featuring a Low Emissions Pack to minimise environmental impact.

The Low Emissions Pack comprises three key features including an ultra-clean diesel engine, which reduces particulate matter by up to 50 per cent versus a standard diesel motor, together with Carrier’s ultra-low noise option kit for quieter operation. This feature reduces noise levels, making it ideal for vehicles being used for urban missions and night-time deliveries. The unit can also be delivered as a City version, which is compliant with PIEK standards, operating below 60 decibels.

Also included in the Low Emissions Pack is the use of R-452A refrigerant, which has the same cooling capacity, fuel efficiency, reliability and refrigerant charge as the standard R-404A refrigerant, but offers a 45 per cent reduction in Global Warming Potential (GWP). The new R-452A refrigerant is optionally available in place of R-404A refrigerant throughout the Vector, Supra and Pulsor™ ranges.

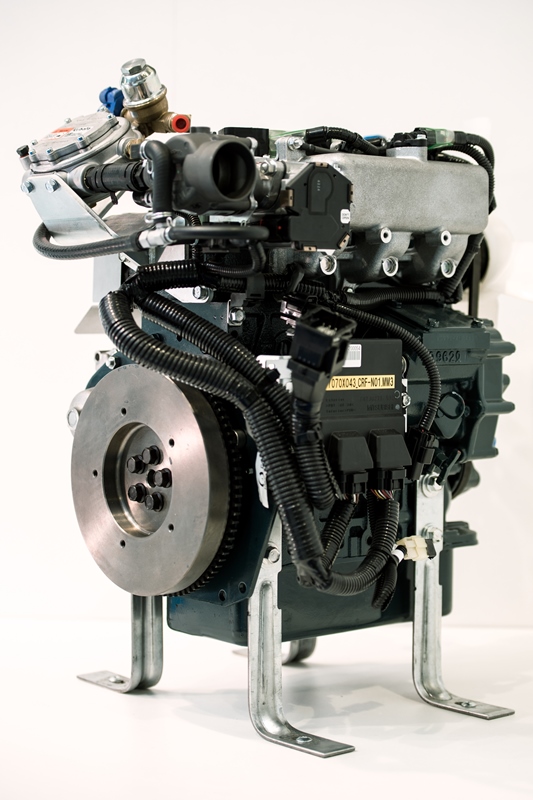

Compressed Natural Gas (CNG)-Powered Supra

The stand also features a video highlighting Carrier Transicold’s prototype CNG engine. This new power source enables a significant reduction in polluting emissions, 95 per cent in particulate emissions, 70 per cent in nitrogen oxide emissions and noise emissions. This may also provide savings in running costs too, as the price of CNG as an operating fuel has been consistently lower than diesel.

Carrier Transicold is currently designing a prototype of the engine, as an important first step toward using a CNG engine for transport refrigeration. It is designed to be fitted with an independent fuel tank, allowing for full autonomy of the refrigeration unit.

Vector 1950 MT Trailer Unit

Joining the Supra unit on display is a Vector 1950 MT (multi-temperature) trailer refrigeration unit with R-452A refrigerant. Delivering a high cooling capacity of 18,875 watts, the Vector 1950 MT is well suited to maintain precise temperature control of sensitive goods on intensive distribution routes with multiple door openings. Multi-zone control allows for a flexible trailer configuration whilst the 5,700 m3/h airflow helps to protect the cargo with unparalleled pull-down speeds and even air distribution.

Pulsor Units for Pharmaceutical Missions

Carrier Transicold is also featuring a unit from its Pulsor light commercial vehicle range in its stand, one of the handful of high-performance units, which is ideally suited to transporting pharmaceuticals. Pulsor systems stand out for its ability to reach full refrigeration capacity at engine speeds as low as 1,000 rpm. This means they can maintain temperature integrity throughout the delivery cycle even when making deliveries in congested city centres.

The units also offer the ability to simultaneously cool and heat different compartments within the load space at the same time, maintaining chosen set points between -25 and +30 degrees celsius in outside temperatures of -25 to +50 degrees. This temperature range makes them ideal for operation in Europe year-round, with precise temperature control to within 0.8 degrees of the set point.