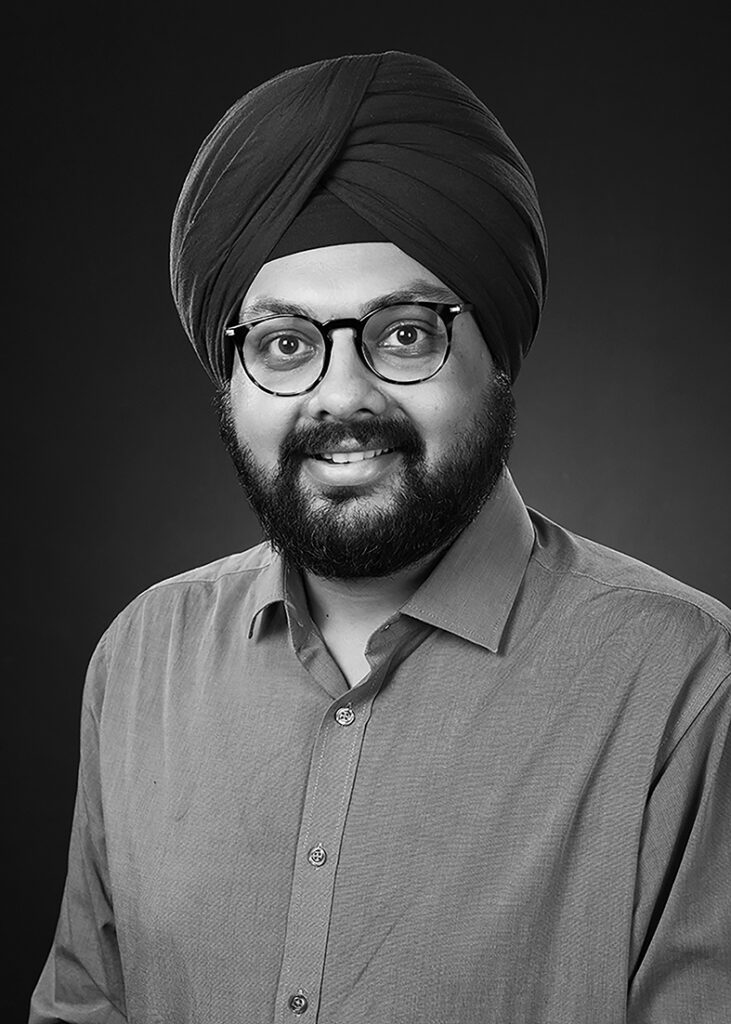

EVs today are a busy playground world over. And, mushrooming are companies and start-ups that make EVs or EV components to push the EV age forward. So, how does another start-up, EVage, set itself apart from the competition? EVage opts to play in the last mile delivery vehicle segment – a vital link in the supply chain which no one else has focused on. Inderveer Singh, Founder and CEO of EVage lays it all out in simple terms to N Balasubramanian.

EVage was born in 2014 and incorporated 5 years later today has garnered attention by making India’s first exoskeleton structure for an electric delivery van. The founders of EVage – Pulkit Srivastava and Harnoor Kaur – along with Inderveer Singh, together take care of the company’s business, digital manufacturing and technology respectively. EVage has been bootstrapped till now and is now getting into their first fundraising activity.

Inderveer Singh – Founder and CEO, Technology and Manufacturing, EVage shares: “We have built it from the ground up and we are looking at a formal launch in the first quarter of 2021. When we began in 2014, the electric mobility supplier ecosystem was missing. It was our conscious decision to make aerospace inspired structures, and the people in our team are scientists from the international aerospace industry. Understandably, our journey in the last six years has been speckled with issues just like any start-up would while trying to develop a product from the scratch. And now we have the vehicle ready.”

EVage’s last and mid-mile delivery vehicles would be 4-wheel commercial delivery vans and mini trucks running in urban environments.

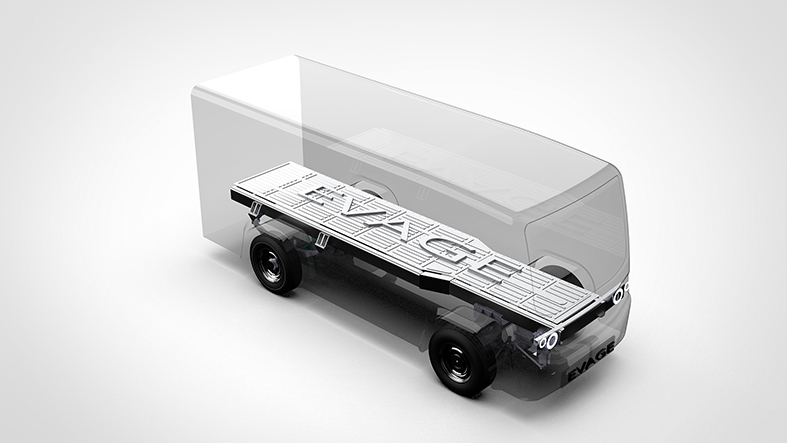

Light and Modular in Design

If ‘Make in India, For the World’ is one differentiating factor for EVage, the other is the ability to offer 3 advantages in the form of light weighting, modularity and manufacturability.

Singh elaborates: “It is not only about going green in transportation. In logistics, decisions are driven by how much value we create for the users. So, the second USP is our ability to offer light weighting and modularity, which leads to higher number of efficiencies for the fleet operators. Thirdly, our manufacturability is extremely efficient which ensures that we can focus on better economics in the long run.”

He says further: “The automotive industry has no precedence to make vehicles ultra-lightweight, super durable, reliable and also extremely modular in nature. But other industries do, like aerospace. EVs have a simple motor which does everything and it brings great simplicity to the design. This affords us the leeway for modularity, and innovative manufacturing could be done on top of that. We have imparted global standards of engineering, and technology development right here in Chandigarh, India. So, it is a matter of pride for us as a company.”

Disruption – From Physical to Digital Showrooms

Singh feels that one of the biggest disruptions would be in how physical showrooms will give way to digital showrooms when it comes to EVs.

He explains: “In EV segment, the biggest disruption coming would be in the downstream. The current business model in automotive industry is that retail is done through showrooms, and the dealers, and distributors earn major profits from servicing. And, servicing as a percentage of costs involved annually would be about 1/10th for an EV compared to a combustion engine vehicle which will question the viability of the dealerships. We are of the opinion that digital showrooms will be the way to go in the future. And we will explore the digital retail formats for our vehicles.”

Even globally, the trend indicates moving away from brick-and-mortar showrooms but it is yet to pan out in the Indian context. EVage is planning for a regional launch when it happens and that too in a phased manner because they are still creating infrastructure for servicing.

Singh is hopeful that EVage will have its presence across India in the next 12-18 months and the first phase of launch will be in North India.

Advantage EVage

EVage has invested in its own test track where they put miles on the vehicle in preparation for the launch.

Singh says: “We have been testing the vehicles for the last 2 years and have crossed 150,000 plus kilometers. We have tested the vehicles under different load and road conditions, different incline and decline statuses. And now, we are fairly confident to release this vehicle into the hands of the consumers because we know its reliability, performance, and that it meets the consumer requirement.”

EVage has given a common architecture on which 5-7 different platforms can be built.

He agrees: “This makes it highly modular so that we can quickly ramp up to different models using the same architecture without losing time and money.”

The company is looking at catering to different customers’ needs to grab the market share when it launches the vehicles.

Singh explains: “We believe that there will be a need for building purpose-built vehicles when EVs become more of a trend. For example, an online e-retailer and an online fashion apparel company will need two different kinds of vehicles for efficient deliveries. But the volumes will never justify custom built vehicles, currently. But with our architecture, we can churn them out on the same production line without adding new lines.”

Exoskeleton Structure

EVage has worked on optimizing the structure where the loads are analyzed and then the cross-section thickness is optimized wherever needed. Their preferred material to work with is aluminium.

He shares: “We are opting for aluminium majorly in all our chassis and structural work because it is light in weight and corrosion resistant. We have optimized our own alloy which was custom-made for us. And, we use composites for the skin of the vehicle just like in aircrafts. The composites we have developed is about four times lighter than steel and the strength is almost 2-2.5 times more than steel. It makes the skin stronger and highly durable yet super light.”

The multiple crash tests have thrown up positive results too. Singh shares: “We have crash tested it and have the videos of the vehicle running on the track to showcase the durability of it. And because it not any composite material and the way we manufacture these composites that define how the material will yield. When it comes to repairability of say a scratch, dent or a crack, we apply a few chemicals that integrate into it and it is repaired. This is a localized repair function where it would be more cost effective to repair this when compared to steel.”

EVage is looking to apply for over 20 patents on repairability technology, light-weighting, modularity and thermal management technology that they have developed. And the vehicles are in the process of obtaining their certifications from ARAI.

Localization and Market Share

EVage believes in localization as far as possible. And the founders are hopeful that critical components such as cells will soon be made locally.

Singh says: “When we began building EVs from the ground up in 2014, China was making components for high-end vehicles which were used in the developing countries but they did not have the ecosystem to make urban trucks which are suitable for Indian context or other developing countries. EVage did the bulk of the work sourcing locally. Critical components like motor controllers, BMS, even the pack design is localized, though cells continued to be imported.”

Singh, his co-founders and their team of 30 engineers are planning to ‘have a sizable chunk of the last mile delivery vans in the next couple of years’. They are looking at capturing a considerable market share in the delivery vehicle segment.

He elaborates: “Our approach right now is to focus on the key fleet owners that we have been talking to and get the vehicles on road, pile on miles. We are looking at getting more customer validation and try to fulfill their demands as far as possible.”

Vision

In the mid-term, competing globally makes up a part of EVage’s vision. Singh agrees: “It will be taken up in a phased manner. Our architecture, and the components that we have are reliable enough to compete globally. There will be some adaptations for left-hand drives and other iterations too. But we hope to be a global player in the next couple of years, and there is already quite an interest that we are generating globally.”

EVage’s long-term vision involves becoming pioneers of sustainable transportation in India and in the world and the company is gearing up to it.

Singh feels: “Globally, it is the luxury vehicles that are selling. The actual transportation would happen when electric mobility gets integrated into the daily lives of people. And that is what we are doing as a company. We are getting the daily deliveries electrified. We plan to help companies reach their environmental and sustainable targets to make cities better places to live in. And we are pioneering this because we believe that we are the only ones who are looking at things that matter.”

And why not! For, EVage is working on saving the world one electric vehicle at a time!

—

“We have built it from the ground up and we are looking at a formal launch in the first quarter of 2021. When we began in 2014, the electric mobility supplier ecosystem was missing. It was our conscious decision to make aerospace inspired structures, and the people in our team are scientists from the international aerospace industry…

– Inderveer Singh, Founder and CEO, Technology and Manufacturing, EVage