Eicher has come out with the Pro 6035T with an aim to raise the bar in the highly demanding heavy-duty tipper segment. N. Balasubramanian takes the vehicle for a spin to get a first-hand experience of what all the dashing new yellow machine has to offer.

The heavy-duty tipper segment is rapidly evolving and becoming more demanding in terms of better fuel efficiency, faster turnaround and higher uptime, along with driver safety and comfort. One of Eicher’s latest offerings in the segment is the Pro 6035T, built on the philosophy to ‘Do More’, with a promise of delivering unmatched performance and a much improved value proposition for customers.

The new Eicher Pro 6035T is a next-generation 35-ton GVW 8×4 tipper targeting segments like sand, stone quarry, irrigation/earth work, port, iron ore, coal, blue metal and limestone. The vehicle is available with CBC and fully-built variants of 20 & 23 cu.m. box body and 16 & 18 cu.m. rock body.

The Pro 6035T is Eicher’s first 12-wheeler offering in the mining segment and is the company’s answer to customers’ demand for a product capable of carrying more load without any compromise on uptime and fuel efficiency. Buoyed by the proven and tested aggregates that have gone into the vehicle, the company is confident that the vehicle’s specifications are more than enough for the different range of applications they will be deployed for.

Initial Preparations

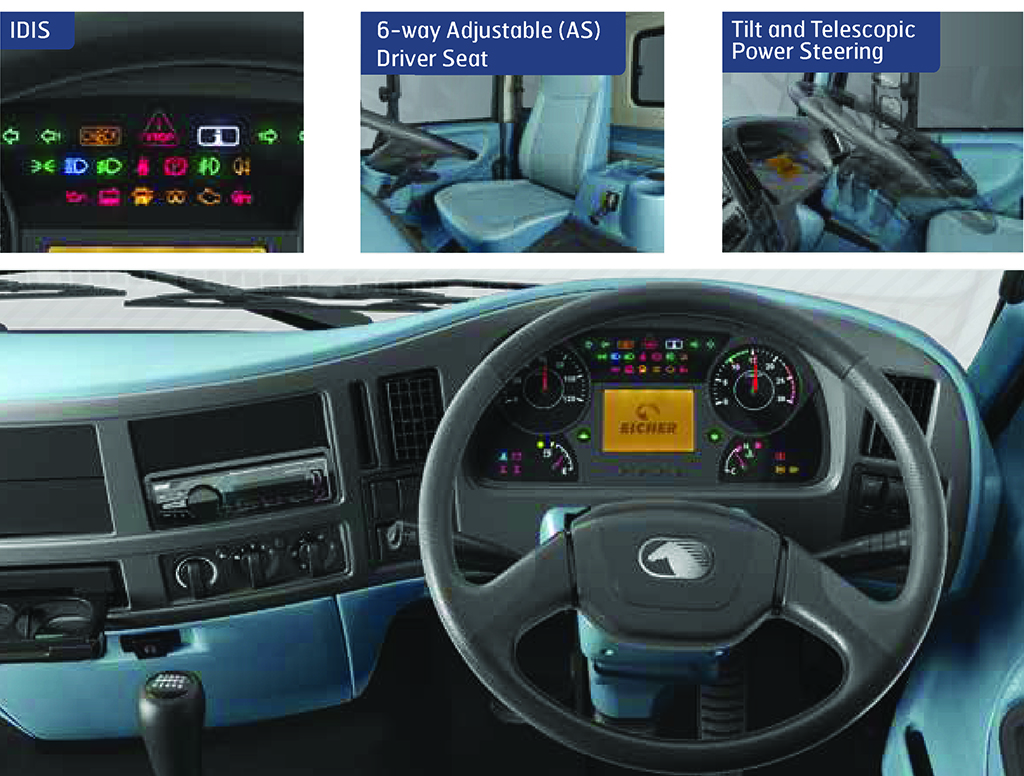

The first task after entering the cabin was to get settled in the nice, comfortable driver seat, making adjustments to the seat and the steering wheel. As in today’s modern day CV cabins, everything from the seat adjustments, the indicators on the cluster to the view of the road ahead, side and rear mirror views, were absolutely perfect, contributing to a really good cabin experience.

The ergonomically-designed cabin comes with improved suspension for better driving comfort and has cruise control and standard HVAC for fatigue-free driving. The vehicle’s parabolic suspension further adds to the driving comfort while the 6-way adjustable suspended seat and tilt & telescopic steering make the feel of occupying the driver seat a truly comfortable and pleasant one.

Time to Rev

Once the engine was cranked, we were ready to move. The tipper is equipped with the proven VEDX8 6-cylinder engine clubbed with Volvo Group’s Engine Management System & compact Box type EATS with Vanadium-based SCR for best-in-class fluid efficiency. The engine delivers a max power output of 260 hp at just 2200 rpm and flat torque of 1000 Nm @ 1000-1700 rpm thereby resulting in significantly lesser fuel consumption than competition.

Before the wheels turned, it was imperative to get a clear understanding of the gear positions of the 9-speed gearbox and get some practice gear shifts done. The gearbox has two neutral positions, with the gear level being slightly more tilted than usual in both positions. As guided by the Eicher driver trainer who accompanied us during the drive, the initial acceleration was done gently to try and keep the rpm at an optimal level. The target was to stay within the green band rpm – 1200-1800 – which ensures best fuel economy. Though we moved up only until gear six during our runs before taking turns and trying out some reverse moves, the actual USPs of the vehicle come into play when the vehicle is fully loaded, while passing through gradients and navigating more challenging terrain. The tipper comes with a crawler gear ratio of 14.68 which is markedly higher than other vehicles in the segment, designed to give customers an edge over their peers.

Ingredients for a Smooth Drive

The chassis of the Pro 6035T is built using high strength DOMEX material, adding to its strength and reliability while its robust driveline, bogie suspension and other reliable aggregates ensure the truck is available for use at all times instead of lying idle in the workshop. While normal braking is pretty smooth and sharp depending on the necessity and brake application, the high performance engine brake helps minimize engine overrun and improve service brake and tyre life.

The vehicle’s higher power-to-weight and torque-to-weight ratios help in higher average speed, thereby ensuring better pick-up which in turn paves way for more trips for the customer. The turns are pretty smooth and comfortable thanks to the lower turning circle diameter, while crossing slopes are equally smooth given the fine grade-ability of the vehicle. The tipper also comes equipped with inter axle differential lock that ensures easy operation on tough and slushy roads which are quite common in the applications the vehicle has been built for. On long stretches, the cruise control option, a standard on all Eicher HD trucks, is something which drivers would enjoy a lot.

Once we take the vehicle for a few runs on long stretches coupled with some interesting turns, we are bound to get used to the vehicle’s core functioning post which it becomes a lot easier to steer, shift gears and get the best out of the machine as far as fuel efficiency is concerned.

Prioritising Fuel Efficiency

Last year, Eicher came out with an announcement that all its newly-sold trucks and buses would be 100% connected. Driving the Pro 6035T gave a good first-hand ‘connected’ experience. The advanced on-board diagnostics (OBD), one of the highlights of the vehicle, displays fault indicators in the form of audio and video signals for preventive maintenance while a 4-way Engine Protection System ensures the engine remains safe with the least possible maintenance.

The tipper has an Intelligent Driver Information System (IDIS) which continuously guides the driver with the truck’s operational parameters. It includes an industry-first fuel coaching that provides real-time guidance for improved driver efficiency and fuel economics while the M Booster+ offers multi driving modes to optimize acceleration and maximize fuel efficiency.

The instrument cluster indicates errors in the form of symbols to make it easy for drivers to interpret them and take corrective action. And, the corrective action is not left to the driver alone; through the vehicle telematics, all errors, especially critical ones, are monitored remotely by the OEM’s Uptime Cell who will contact the customer in case of any emergency or serious issue and direct them to the nearest dealer or service touchpoint from the vehicle’s current location. Through the fuel coaching technology, indicators such as thumbs up / thumbs down appear on the cluster, instructing the driver to either reduce the rpm or shift the gear to ensure the best fuel efficiency is achieved.

When a customer buys the vehicle, a Vehicle Introduction Process (VIP) is done at the dealership during the vehicle handover. Following that, Eicher’s driver trainer offers basic driver training for the customer to ensure the vehicle is used in the most efficient way and all features are completely understood and put to use. In addition, the company also offers hands-on driver training to help customers achieve the best possible mileage for the vehicle since fuel efficiency stands on top priority for both the customer and the OEM.

During driver training, hitting the sweet spot – shifting gears at the right rpm – leads to accumulation of points for the driver. After a round of training, the points for different drivers are assessed to find out how well each one is driving. Customers also track the same and request the OEM for training if their drivers are unable to deliver the fuel efficiency promised by Eicher’s driver trainer.

On the whole, Eicher has come up with a winning product in the Pro 6035T. With construction and mining among the high growth segments in the Indian CV industry, the product should give good impetus to Eicher’s position in the tipper space.