Economical networking solutions, from diesel technology to hybridization

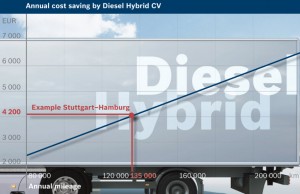

Potential savings: In all, Bosch technology can reduce commercial-vehicle fuel consumption by an additional 15 percent by 2020. Given today’s fuel prices and a total annual mileage of 135,000 kilometers, this means a reduction in operating costs of some 10,000 euros per vehicle per year.

“Efficiency comes first not only under the hood, but also at the wheel. We know that economical solutions play an especially important role in the commercial-vehicle segment,” says Wolf-Henning Scheider, member of the board of management of Robert Bosch GmbH and spokesperson for the Automotive Technology business sector.

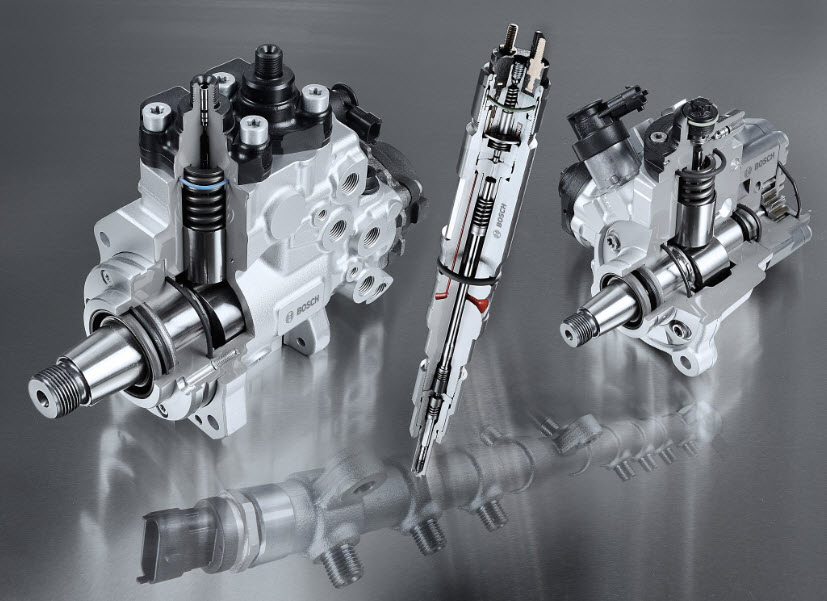

Powertrain technology: diesel expertise from injectors to exhaust-gas treatment

Systems supplier: Bosch supplies all necessary core components for commercial-vehicle diesel powertrains from a single source. The portfolio ranges from sensors and injectors to exhaust-gas treatment using Denoxtronic.

Common-rail system: Bosch’s CRSN3-25 alone saves up to 1 percent fuel, a saving of nearly 700 euros each year. With an injection pressure of 2,500 bar, the system can be flexibly configured to meet the specific requirements for exhaust-gas treatment and exhaust-gas recirculation. Bosch’s CRSN3-25 is leak-free in both low- and high-pressure ranges.

Heavy-duty starter: The new, powerful HEF109-L type starter achieves an 18 percent more dynamic starting performance. It delivers up to 9.2 kilowatts, which is enough to reliably start diesel engines with up to 28 liters displacement. Remarkably compact, the HEF109-L heavy-duty starter is particularly suitable for use where engine compartment space is limited.

Turbochargers: The Bosch Mahle Turbo Systems GmbH & Co. KG joint venture has been manufacturing exhaust-gas turbochargers for commercial vehicles since 2012. The product portfolio includes six basic variants for engines delivering anything from 30 to 520 kilowatts.

Exhaust-gas treatment: The Bosch subsidiary Bosch Emission Systems GmbH & Co. KG (BESG) supplies complete plug-and-play packages for exhaust-gas treatment. It can tailor systems for individual customers and take over integration into vehicles or machinery, including certification.

Bosch Emission Systems GmbH & Co. KG supports manufacturers of engines and vehicles all over the world as a reliable partner

Brake control system: ESP 9TE for commercial vehicles up to eight tons will be fitted as standard to a new model of an US truckmaker from late September. Designed specifically for the North American market, the brake control system builds up brake pressure quickly. This makes ESP 9TE ideal for vans and pick-up trucks, with their longer wheelbase and larger calipers.

Alternatives: CNG powertrains, electrification, and waste-heat recovery

CNG: This fuel is particularly inexpensive and also emits less CO2 dbiburing combustion. Bosch offers a complete system comprising control units, sensors, and injection valves. In 2015, the company will equip almost 50,000 commercial-vehicle engines with CNG systems, twice as many as in 2014. Over the long term, this market will grow in both China and North America.

Boost recuperation system: Bosch offers a 48-volt entry-level hybrid for light commercial vehicles. This has several benefits: the system makes fuel-efficient coasting possible, while its higher power means it makes better use of energy recovery than applications based on conventional voltage levels, achieving overall system fuel savings of up to 25 percent.

Hybridization: Delivery vans can save as much as 15 percent fuel through electrification, while heavy trucks traveling long distances can save roughly 6 percent. The goal by the end of the decade is to develop an electric hybrid for trucks that pays for itself within two to three years.

Hybridization: Delivery vans can save as much as 15 percent fuel through electrification, while heavy trucks traveling long distances can save roughly 6 percent. The goal by the end of the decade is to develop an electric hybrid for trucks that pays for itself within two to three years.

Waste-heat recovery: By recovering heat from the engine, fuel savings of up to 5 percent can be achieved. The technology especially reduces fuel consumption at constant speeds on long stretches. Bosch expects to bring this to market by the end of the decade.

Connectivity: from electronic horizons to preventive diagnostics

Smart generator: This component adjusts itself to driving conditions. During breaking and overrun it charges the battery, but it turns itself off during acceleration, which translates into a 1 percent fuel saving. Bosch was the first supplier to offer such a smart generator for commercial vehicles. By 2020, the installation rate will have risen from 3 to 20 percent.

Electronic horizon: The Eco.Logic Motion system uses navigation and cloud data to calculate an efficient driving strategy. By accelerating at the right time in advance of inclines and by avoiding unnecessary gear shifts, a fuel saving of up to 5 percent is possible; measurements taken by Bosch customers indicate that the saving could be as much as 9 percent.

Connectivity control unit: This box uses data communications to connect the automotive electronics with external servers – either to monitor truck trailers or as an onboard device for truck toll systems. The second generation is suitable for LTE wireless communication. It can be used with the software applications of various commercial-vehicle manufacturers.

Preventive diagnostics: Using data from the vehicles’ control units, logistics companies can monitor the wear and tear of their truck fleets over the internet. As a result, maintenance and repairs can be planned at an early stage. In this way, the risk of incidents such as the breakdown of a fully-loaded frozen food transporter can be significantly reduced.

Secure truck parking: This facilitates the online reservation of secure truck parking spaces at rest areas along the freeway. The next step will see Bosch Secure Truck Parking providing video surveillance of premium parking spaces, effectively offering a virtual protective fence for valuable cargo.

mySPIN: This system displays apps on the dashboard. The Bosch solution, introduced in passenger cars this year, is also suitable for additional web applications in trucks, such as Secure Truck Parking.

Driver’s workplace: The cockpit of the future will be one in which security and camera systems are integrated along with telematics and efficiency functions. The ingenious part of the Bosch solution remains hidden – thanks to an electronic resource manager, the driver sees only information that is relevant and useful at any given moment.