For over a century, Eaton has been supplying the global automotive and truck customers with highly engineered products that help increase fuel economy as well as improve the overall efficiency, performance and control of vehicles in a sustainable way.

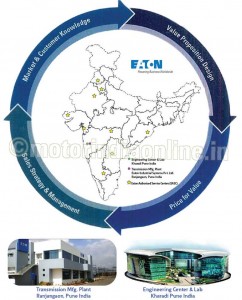

Over last seven years, Eaton has established itself as a reliable technology partner amongst the leading automotive and commercial vehicle OEMs in India. At present, it has three manufacturing plants, a global engineering center and an Integrated Test Lab near Pune, Maharashtra. The investments made in India are testimony of Eaton’s commitment to the growing market.

Off-highway focus

With keen focus on the off-highway vehicle segment, Eaton has an extensive portfolio of products to improve the product utility and vehicle uptime for customers in this field. Eaton has both manual as well as Automated-Manual (AMT) solutions for off-highway applications. While its manual transmissions have already been localized considering the high volume base, its AMTs continue to be in focus for niche applications. Eaton has also another rugged product offering in the form of the Twin Counter Shaft gear box which is capable of meeting torque ratings of up to 2200 Nm.

Eaton’s localized 6-speed and 9-speed transmissions are its most popular products and are preferred for off-highway applications. Its transmissions, which come in 6, 9 and 10-speed models, are recognized for superior product reliability, performance and robustness, with Eaton being the only company in the country to be engaged with leading truck OEMs on engine platforms right from 160 hp to 380 hp. The transmissions cater to a wide range of applications starting from 25MT tippers up to 49 MT tip-trailers. Advantages such as high torque rating, product reliability and India-specific customization, backed by strong all-India service support, gives Eaton a clear edge over competition in the Indian market.

Eaton’s localized 6-speed and 9-speed transmissions are its most popular products and are preferred for off-highway applications. Its transmissions, which come in 6, 9 and 10-speed models, are recognized for superior product reliability, performance and robustness, with Eaton being the only company in the country to be engaged with leading truck OEMs on engine platforms right from 160 hp to 380 hp. The transmissions cater to a wide range of applications starting from 25MT tippers up to 49 MT tip-trailers. Advantages such as high torque rating, product reliability and India-specific customization, backed by strong all-India service support, gives Eaton a clear edge over competition in the Indian market.

Mr. Krishnakumar Srinivasan, President-APAC, Eaton, says: “Eaton will continue to complement the efforts of vehicle OEMs in building vehicles with higher efficiency, reliability and safety. Our endeavor is to offer the best value to the end customer through our products and services.”

Eaton also has a wide range of engine valves which are being supplied to practically every engine manufacturer in India and used on applications such as passenger cars, rail locomotives, HCVs, off-highway vehicles, power generation and aftermarket.

Also in focus for the Indian market are Eaton’s torque management products. The company’s NoSPIN range of differentials, a patented product, offers significant performance enhancement, in form of traction improvement, in off-road vehicles. These can also be replaced in lieu of open differentials for automatic traction control at the rear wheels. Eaton is actively engaged with OEMs for the mass production of the NoSPIN product range which also has very good potential in the aftermarket. The NoSPIN differential is most preferred for applications such as tippers, dump trucks, wheel Loaders, etc.

Also in focus for the Indian market are Eaton’s torque management products. The company’s NoSPIN range of differentials, a patented product, offers significant performance enhancement, in form of traction improvement, in off-road vehicles. These can also be replaced in lieu of open differentials for automatic traction control at the rear wheels. Eaton is actively engaged with OEMs for the mass production of the NoSPIN product range which also has very good potential in the aftermarket. The NoSPIN differential is most preferred for applications such as tippers, dump trucks, wheel Loaders, etc.

Aftermarket support

In addition to its growing presence in the OE segment, Eaton continues to strengthen its aftermarket service support network. Presently there are over 45,000 Eaton transmissions operating successfully on Indian roads, backed up by more than 3,500 company technicians at OEMs and dealerships, all trained by Eaton. There are 11 Eaton Authorized Service Centers (EASC) at key strategic locations across India with the company planning to add few more in the near future, with focus on ensuring 24×7 service and parts support, complementing the vehicle OEMs’ own network.