At Busworld, Cummins launched a new Stop Start system for its ISB engines, the first on the market for conventional buses. As part of the Smart Efficiency initiative it was featured on the Cummins stand (407, hall 4) at Kortrijk Xpo.

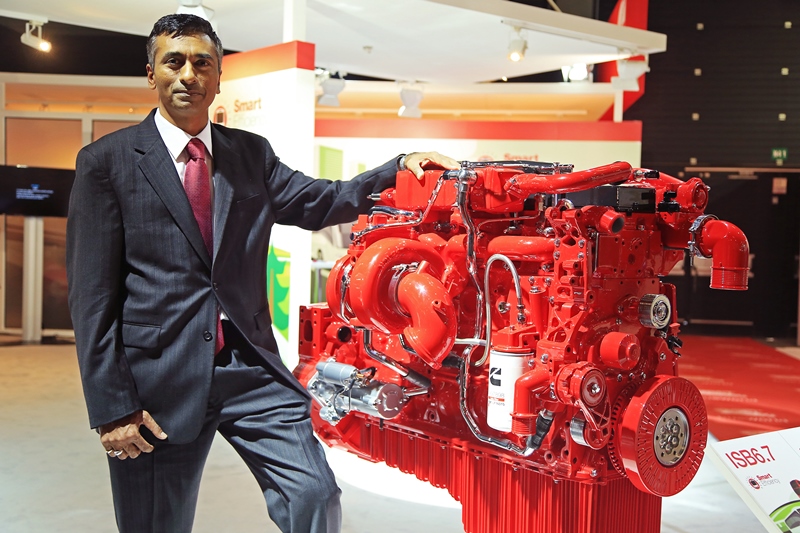

Mr. Kartik Ramanan, General Manager of Cummins Global Bus Engine Business, said: “This is the first stop-start system launched for conventional bus use. It has been developed by Cummins engineers to deliver proven savings for operators with a competitive payback period.”

Stop-start systems have been available as part of diesel-electric hybrid bus technology for some time. However, the high investment cost has prevented many operators from justifying the investment and achieving savings without some level of subsidies.

“We have developed a system that delivers 4-7% fuel savings without significant operator investment needed and meets the durability requirements of city bus duty cycles. A vehicle could stop every minute, so to meet the tough operational needs we have redesigned critical engine components and are validating them across 4 million stop-starts,” continued Mr. Ramanan.

Cummins has made a significant level of hardware updates to the ISB Euro 6 engines to make the technology successful. These include a new starter motor capable of 210,000 start-stop events, a new flywheel and ring gear, new wiring, a new engine speed sensor, an updated fuel system, new con rod bearings and new crankshaft bearings. These, as well as the current engines parts, have all been validated during the test cell and field test program covering both buses and truck installations.

The ISB engine software has been upgraded to manage the technology and provide flexible architecture, enabling customers to choose what they want from it and tailor it to their operations.

Cummins engineers will work closely with OEM customers on the integration to ensure that the bus does not limit the full capability of the stop-start system being achieved. To help customers achieve the greatest benefit from the technology, a training program is being rolled out across those fleets where the buses will initially be working to ensure drivers are familiar with all aspects of its operation.

Additional benefits seen from Stop-Start include passenger and pedestrian comfort with reduced noise and vibration on the bus when it stops, as well as reduced emissions around the bus-stops.

Cummins launch fleet of 100 buses will be going into service in the fourth quarter of 2015, with their performance being closely monitored to ensure they are achieving the expected savings. The full production launch is in March 2016.

“Results so far have been excellent. As along with the 4-7% improvement in fuel economy and CO2 emissions we are also seeing a 30-40% reduction in NOx emissions, supporting further improvements in clean air,” he concluded.