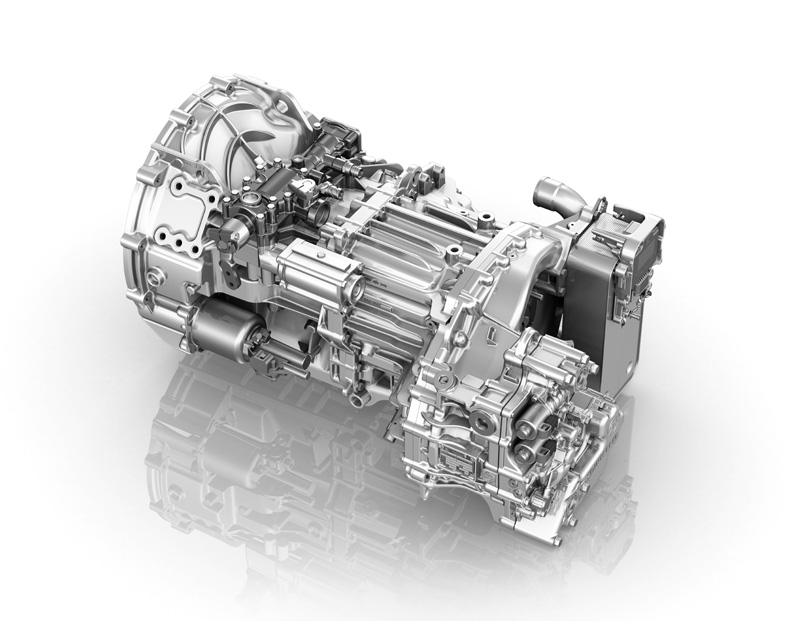

- New ZF-EcoShift manual bus transmission

- EcoLife automatic transmission with smooth start-up performance and low noise

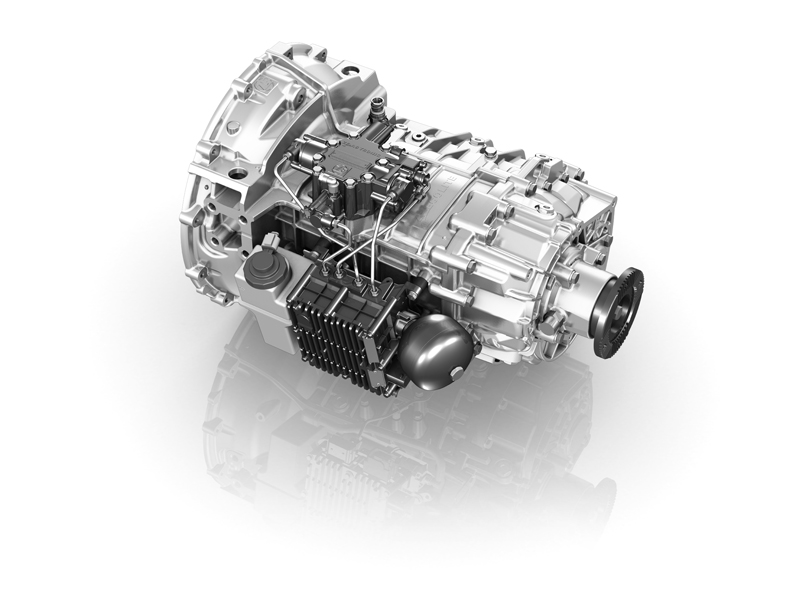

- AS Tronic lite success story – now continued in light buses

ZF boasts a broad product portfolio in bus driveline technology. Products range from the new EcoShift manual transmission, which can be extended on a modular basis, the EcoLife 6-speed automatic transmission, which constitutes a global benchmark in terms of smooth start-up performance and low noise, through to the AS Tronic lite automatic transmission system, which ZF also offers for light buses in intercity bus and coach operation.

With the innovation EcoShift, ZF created a new, state-of-the-art model range of manual bus transmissions that is designed to meet future market requirements. The basis is a 6-speed manual basic transmission which is used as a platform for additional transmission variants and thus forms the basis for a modular kit. The uniform basic transmission allows for standardization regarding the transmission dimensions, mounting position, and possible connections. This means greater flexibility for vehicle manufacturers because they no longer have to decide on one transmission version for a vehicle range. The EcoShift basic transmission is designed for a torque range of 1 000 to 2 100 Nm and is therefore suitable for intercity buses and coaches of up to 24 tons. The new transmission stands out with its lower noise and smoother gear changes. It can also be combined with the Servoshift shift support system and with the wear-free transmission brake ZF-Intarder.

Quiet and fuel-efficient: ZF-EcoLife

In order to be accepted as a true alternative to individual transport, buses operating in inner-city line service must not only have low emissions, they must also be especially quiet. Repeated approach and departure processes at bus stops generate a high noise level for people who live near bus stops, pedestrians, and passengers. Here, exhaust gas and noise emissions are actually two sides of the same coin. After all, anything that has a positive effect on fuel consumption – i.e. very low engine speeds – also feeds through into lower noise emissions. The six speeds of the ZF-EcoLife bus transmission allow for a close gear ratio spread and a high total spread of 12.6 – thus, the engine can be run in the low speed range in any operating condition. The standard TopoDyn Life shift program triggers upshifts as early as possible depending on topography and load, which results, in practice, in a noise reduction for the especially loud setting-off process at the bus stop.

As of its market launch, the ZF-EcoLife has been setting new standards with regard to fuel efficiency: As a result of its topography-dependent control software TopoDyn Life, the ZF- EcoLife needs ten percent less fuel than its predecessor Ecomat. Many technical details contribute to reducing fuel consumption, like for instance the on-demand control of the hydraulic pump. It only provides the complete pump output when driving with full power. The control software not only shifts into neutral position when standing still at the bus stop, but even during rolling and already with a speed of 12 km/h. Like this, engine and brakes do not counteract, which would have a negative effect on fuel consumption.

Automation for the growth markets: AS Tronic lite

The AS Tronic automatic transmission range has been very successful in commercial vehicles for many years. The large 12- speed version for heavy coaches has been the benchmark in this segment since its market launch in 2002. ZF also offers the AS Tronic lite for light intercity buses and coaches. The automatic 6- speed transmission is targeted particularly at the bus market in Eastern Europe, Asia, Latin America, and Africa. These markets are on their way towards higher technological standards but currently not financially strong enough to reach the level of Western industrial nations. For this reason, manual transmissions still tend to dominate here. With the AS Tronic lite, ZF wants to give these countries the opportunity to further advance the automation in intercity buses and coach operation with the available means. The AS Tronic lite is suited for buses with a gross vehicle weight of up to 18 tons, a length of up to twelve meters, and a maximum torque of 1 100 Nm. It electronically controls gearshift and clutch operations and carries these out hydraulically. Impermissible and inefficient gear selections are thus prevented – the driver can switch quickly to manual mode at any time. The new 6-speed transmission’s electrohydraulic shift module is compact, therefore easier to integrate than pneumatic units and it needs no compressed air supply. Furthermore, state-of-the-art, high-performance helical gears allow for minimum noise generation.

Just as all members of the AS Tronic transmission family, the AS Tronic lite convinces thanks to its reliability and high cost- effectiveness characteristics which, in turn, is a benefit for the environment: Vis-à-vis manual transmissions, up to five percent fleet fuel consumption reductions are made possible. Here, reducing potentially negative driving impacts makes a decisive contribution because automatic transmissions always guarantee an optimum gear selection – independent of driver fatigue or distraction. Moreover, with the automatic shifting process, load peaks are avoided which preserves the entire driveline and consequently doubles the service life of the clutch. The electronic diagnosis also contributes to the further reduction in operating expenses because it makes maintenance and repair so much simpler. As a result, the bus is optimally available in practical service.