In a systematic approach that starts with the peak pressure of 2,500 bar delivered by its common-rail system, Bosch is making commercial vehicle powertrains energy-efficient, reducing emissions and slashing the costs for every kilometer driven. “Our efforts to further increase efficiency start with fuel injection systems and continue on consistently all the way to exhaust-gas treatment,” says Dr. Markus Heyn, president of the Diesel Systems division at Bosch.

At the heart of these efforts lies Bosch’s integrated approach that ensures that powertrain systems and sub-systems harmonize reliably and perfectly.

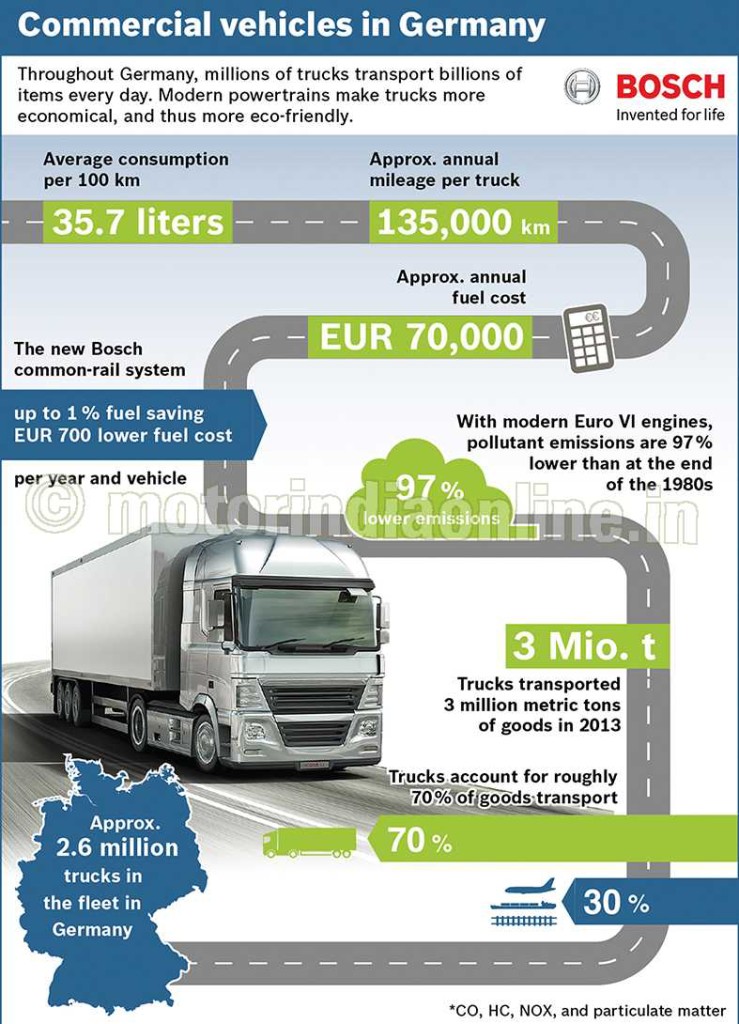

Advanced Bosch powertrain solutions enable commercial-vehicle operators to lower their operating costs. Even though modern truck diesel engines already work at close to the thermodynamic optimum, Bosch’s innovations enhance powertrain-system efficiency even further. The decisive factors here are developments on the micro level, such as the new CRIN3-25 injector, which prevents fuel from ending up unused in the return line. As a result, the new Bosch common-rail system can achieve fuel savings of up to one per cent, saving costs by as much as 700 euros a year. But truck operating costs also depend on the amount of AdBlue that is required to scrub oxides of nitrogen from exhaust emissions.

The Bosch Denoxtronic metering system enhances efficiency by variably matching urea-solution injection to the region of the world in which the vehicle is being used. This allows vehicle manufacturers to precisely customize their powertrain design.

In regions where AdBlue is expensive, Bosch can offer a systems approach that is designed to accommodate high pressures and high levels of exhaust-gas recirculation. In areas where urea is cheaper, the Bosch system aims to maximize combustion efficiency with high excess-air volumes. In this case, the combined effect of the common-rail system and Denoxtronic can produce diesel fuel savings of up to five per cent.

Regardless of the configuration, SCR systems are the key to meeting demanding emission standards such as Euro 6, and the Bosch Denoxtronic urea metering system is the essential part of this solution. As a result of the legislation that came into force in Europe this year, pollutant emissions from modern truck engines are around 97 per cent lower than they were at the end of the 1980s. Thanks to Bosch’s optimized common-rail system, CO2 emissions are also decreasing. Given the several millions of trucks that transport goods throughout Germany every day, the smallest of improvements can make a big difference. Fuel savings of just one per cent per kilometer would lower annual CO2 emissions by more than 300,000 metric tons.

CRSN3-25 common-rail system

Bosch’s new 2,500 bar system is based on a modular systems approach. Bosch’s CRSN3-25 is leak-free in both low and high-pressure ranges. Injecting the compressed fuel that has been delivered with as little loss as possible contributes significantly to greater efficiency throughout the powertrain system. Bosch has designed a system that prevents gap leakage through which fuel can escape unused into the return line.

As well as improving efficiency, the ultra-precise, leak-free injector also ensures a cleaner fuel burn, with a corresponding reduction in particulate and other emissions. What’s more, because the system pressure is retained for a long time, vehicle operators also benefit from the excellent re-start response this offers in start-stop operation.

Exhaust-gas treatment with Denoxtronic

As the amount of fuel consumed during lean operation goes down, so the nitrogen-oxide emissions of an engine typically increase. This conflict of objectives represents a major challenge for commercial vehicle manufacturers. When it comes to making even large commercial vehicles compatible with extremely tough emissions standards such as Euro 6, the Denoxtronic urea metering system is the ideal component for the exhaust-gas system. Because it works without compressed air, it is a system that is as efficient as it is cost-effective.

During development, Bosch placed particular emphasis on creating a robust design and compact configuration. Compared with the previous generation, the size of the delivery module in the latest Denoxtronic 6 was reduced by about a third. In addition, the module guarantees a high throughput of AdBlue without allowing fuel to condense on the walls. This increases efficiency.

The avoidance of plastics as much as possible allows the metering module to be used for continuous operation at ambient temperatures of up to 140 degrees Celsius. This robustness gives commercial-vehicle manufacturers more freedom when integrating the component in their exhaust systems. For this purpose, Bosch Emission Systems GmbH (BESG) provides turnkey projects, assuming responsibility for the purchasing as well as for the definition and integration of all components for exhaust-gas treatment.

Bosch particulate matter sensor

Sensors are powertrain sleuths, continuously gathering accurate, up-to-date data from the exhaust system. This data is the basis for all functions, from mixture formation to clean combustion to exhaust-gas treatment. Besides the usual sensors for determining the powertrain’s exact operating mode, Bosch also offers NOx sensors for SCR-system monitoring and control and sensors for monitoring the diesel particulate filter.

The new particle sensor from Bosch is designed specifically for commercial vehicles and for installation in the exhaust emissions box. It is highly sensitive and is therefore able to work reliably even at low exhaust-gas flow rates. In addition, the sensitivity can be increased by adjusting the tilt angle during installation. The sensor enables the reliable detection of malfunctioning in the diesel particulate filter, and is compatible with both the CAN data bus and the HDSCS technology that is standard in commercial vehicles.

It goes without saying that the Bosch NOx sensor meets the high standards of reliability that apply in commercial vehicles. It is suitable for worldwide use in commercial vehicles, in both 12- and 24-volt systems. It can measure high NOx concentrations of up to 3,000 ppm, but features compact control electronics that are able to evaluate even very small sensor streams as well.