Even if the ongoing pandemic has made a slight dent in the India operations of ADR Group, manufacturers of axles for trailer and agricultural applications, the company’s vision continues to be as clear as ever, says the company’s President, Flavio Radrizzani, in this exclusive interview with N. Balasubramanian

What is the current status of operations at ADR’s production facilities in India and Italy?

All our plants in the world are now operational. Our ADR Italy plant has a rich history of 60 years and is the base for the group’s head office. We have a well-established global business for agricultural axles with tractor OEMs like John Deere, New Holland and others, and many of our projects are actively underway in different countries for different applications. ADR Italy has research and development facilities approved by TUV and it is always busy with new developments and new homologations.

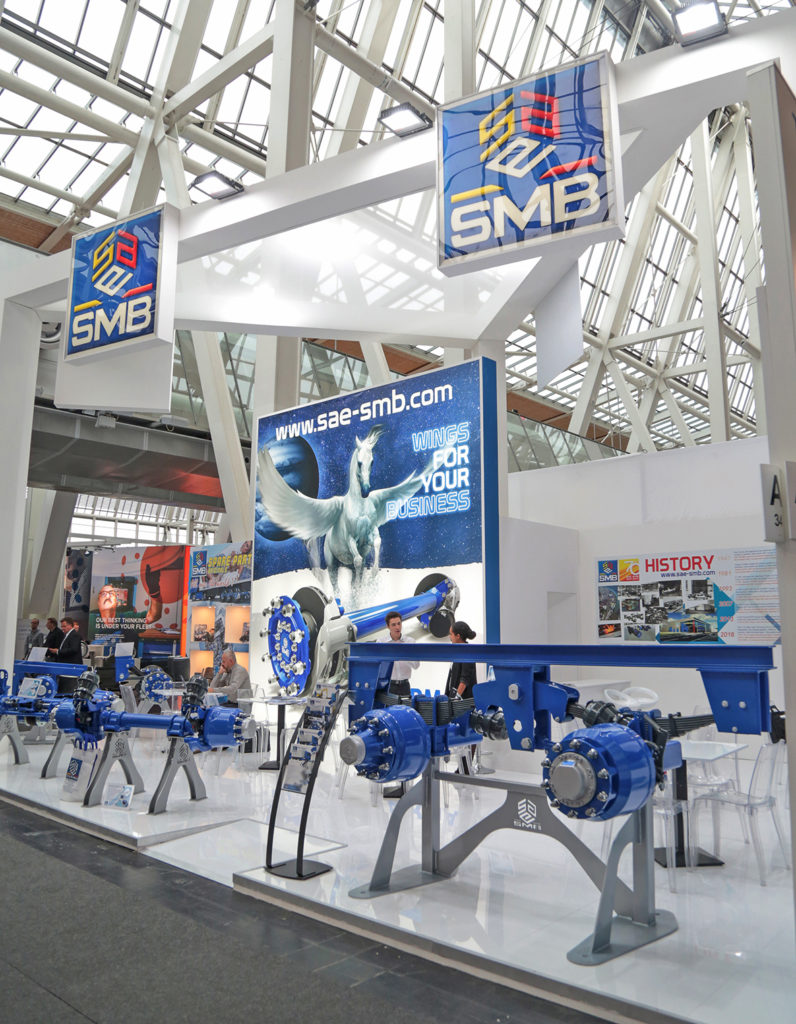

Our subsidiary in India, ADR Axles India (P) Ltd., represents two brands of the group. The ADR brand is mainly for agriculture and industrial applications and the SAE-SMB brand is for road trailers applications. We started operations in India only three years ago and are in the process of introducing our brands in the local market. We are also in the process of investing in a new production plant in Pune. We have forayed into India with a long-term vision and despite the spread and impact of the pandemic we are even more convinced that India can soon become an export hub as is the case now with our plant in China.

ADR axles are appreciated and recognised in the world as a premium product. In India, there is as yet no regulation for mandatory requirement of brakes on trolleys while in the rest of the world it is already a compulsion. In India, ADR has started to introduce various options of brake systems on axles for agriculture application. This aspect is important because brakes on trolleys are a safety feature and can help to reduce the number of accidents. Presently a lot of education and awareness is still required and the government too needs to invest efforts to make the brake system compulsory at the time of registering an agricultural trolley.

How would you sum up the impact of the pandemic on your business both globally and in India? And how have you coped with the challenging situation?

The pandemic has had a global impact for sure, but it has affected our factories in different ways depending on the location. For example, the ADR Italy plant was closed only for seven days during the peak of the pandemic. In India, we had to follow the lockdown order of the government and we stopped operations for about two months. This has of course had an impact on business because some of our customers cancelled or postponed their orders and in some cases the demand reduced drastically. Probably the Indian market is in a more critical situation as compared to others. The commercial vehicles market is still not able to restart and OEMs have had to downscale their production plans.

The Indian market was going through a challenging phase even before the onset of the pandemic and now the situation is even worse. What are your expectations from the rest of the year in terms of customer orders and product sales and what is your strategy to handle such a crisis?

The market is slowly restarting almost everywhere in the world and our factories are back to their full production capacity. Anyway, in India we do not see at the moment a fast recovery curve. The market was already slow in 2019 and the pandemic and resulting lockdowns have put the brakes on any progress in 2020. In this difficult phase we have continued to be very close to our customers. We are ready to support them with our services and we have sufficient stock to meet any urgent requirement. As said earlier, we came in India with a long-term view and we are working on many projects with different customers. We are designing new solutions to meet the typical requirements customers in India. This crisis will pass and we want to be ready when the moment will come.

While there are numerous challenges that the pandemic-related crisis has thrown up, what according to you are the opportunities that may arise from this scenario?

As I explained, the application of brake system in small trolleys is still not regulated in India and this is, in our opinion, a big opportunity if the government takes a proactive step and introduces this improvement to make Indian roads safer.

There is a lot of discussion on India gaining an upper hand over China as a result of the pandemic. What are your thoughts on this issue? Do you expect your India business to benefit from such a development?

We strongly believe that India can become an export hub. We arrived here with this vision three years ago and now the pandemic has confirmed that we have had the right vision. We are investing to build a high-end factory that will produce for the Indian market and for exports as well. We started our plant in China 12 years ago and now the export business model of China is well-established. We are bringing our experience to India to have a second hub in Asia. We are convinced that we need to have an alternative to China, and among all the other emerging markets, India is the most interesting.

How has the pandemic influenced your medium to long-term business plans, say for about the next 5-10 years, both globally and with respect to the Indian market?

In our opinion, the pandemic has had an impact on day-to-day activity but it has had no impact on our medium and long-term plans. We have many projects with new developments in the pipeline. We have many customers in different countries. In India we had to close the factory during the lockdown but we have not stopped working on our long-term projects.