Discusses bringing digitization to shop floor and beyond

The Automotive Component Manufacturers Association of India (ACMA) successfully hosted the third edition of ACT Summit in Pune on December 8-9. The ACT Summit focused on the theme of ‘Digitising Auto Component Industry in India- Creating Smart Factories’.

The ACMA Centre for Technology (ACT) Summit brought together national and international experts in the field of Industry 4.0, who deliberated and presented case studies on the advantages of automation and digitisation. An exhibition on innovations, coinciding with the summit, showcased what lies beyond automation for the automotive industry.

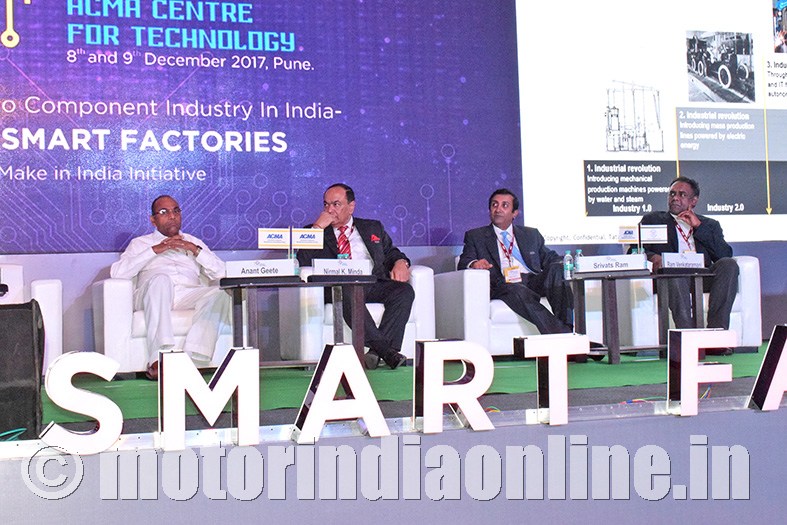

The summit was graced by eminent personalities and dignitaries such as Mr. Anant Geete, Union Minister for Heavy Industries & Public Enterprises, Mr. Tom Flack, President & Chief Procurement Officer, Tata Motors Ltd., Mr. Nirmal K. Minda, ACMA President, and Chairman & Managing Director, UNO MINDA Group, Mr. Ram Venkataramani, ACMA Vice President, and Mr. Srivats Ram, ACT Chairman. Coinciding with the Summit, the ACMA Annual Awards were presented, honouring excellence in auto component manufacturing.

Building smart factories

A key parameter of creating smart factories is implementing digitisation with the help of the Internet of Things and understanding data. At the inaugural session members raised several points in this regard. “The Internet of Things which is connecting everything to the Internet, and machine-to-machine communication, is possible through digitisation, and this is something that will take us to smart factories. If data is made available for everyone, it will improve productivity and knowledge of the resources,” said Mr. Srivats Ram.

Emphasising the impact of digitization, Mr. Nirmal Minda observed: “Digitisation will establish the foundation of Smart Factories of the future. It has the potential to increase our competence in the global market.”

Mr. Anant Geete who was the chief guest on the occasion, said: “Today India is adopting global technology, but we have to build a future where India develops technology for the world. With this in focus, I appreciate the unparalleled efforts put in by ACT for facilitating adoption of international best practices in the auto component industry. I compliment ACMA on its efforts to drive the industry forward in a responsible manner, and assure that the Government will extend full support to ACMA”.

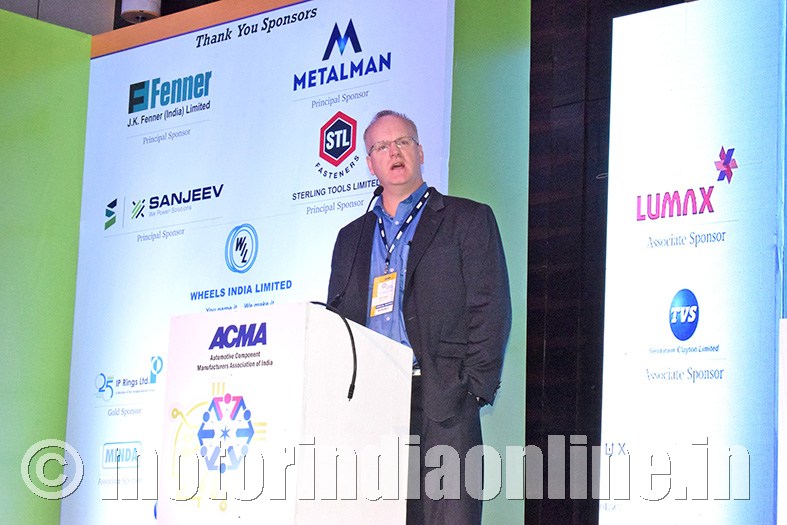

With his lucid comments on smart factories, guest of honour, Mr. Tom Flack said: “One of the misconceptions about Industry 4.0 is that it is expensive and it does not pay back. We need to focus on zero defects, and on quality first and then the cost. The Indian automotive industry is going through a transformational period, especially with the concept of mobility undergoing a dramatic change. The auto component industry must welcome and embrace the digital revolution to stay competitive and relevant; the time has come for the industry to graduate to Industry 4.0 for better predictability and proactively addressing customer requirements. The auto component suppliers need to become ‘full solution’ suppliers from being ‘build to print’. Industry 4.0 is no more about measuring results, it is about predicting and proactively changing the results.”

Digitisation in Quality & Productivity

With an aim to explore smart manufacturing solutions and digitization in the industry, the event had incisive sessions addressed by distinguished industry luminaries that focused on improving quality and drive towards smart manufacturing, keeping in mind the concern for environment and sustainability.

Moderated by Mr. Ashok Taneja, MD & CEO, Shriram Pistons & Rings Ltd., the panel discussion on digitisation in quality and productivity threw light on learning steps for digitisation, understanding data and ROI details. “There is a need to introduce new models in the market frequently, and for this we need to be ready, before someone else is ready for the same. Data is the new oil that will ensure the smooth functioning of a factory,” he said.

Clearly the trends are making us go digital. “Like 50 per cent of the parts made today are digital and there is no going back. We have to break the working mechanism of silos and embrace digitisation. With digitisation there is no duplication of data, and this data can be used by everyone in a company which increases productivity”, asserted Mr. Srinath Koppa, Head of Business & Development, Siemens India.

There are generally two conservative notions about digitisation, one that people heading the factories feel it is not for them, and the second that it costs a lot. Mr. Dattatreya Gaur, VP, Bosch India, cleared the doubts by saying that “digitisation has a good ROI and you can recover your investment within 2 years.”

In terms of benefits, digitisation also enables and promotes collaboration. “It helps us in practicing collaboration in a manner which has not been done before. People in real time production cycles can now collaborate and work together. This has been hard to achieve before,” said Mr. Dilip Sawhney, MD, Rockwell Automation India Pvt. Ltd.

The ability of producing more with less increases with digitisation. “Data-based decision making can help to change the culture of the organisation and make it more efficient, because performance measurement becomes easy,” concluded Mr. Tom Flack.

Awards & recognition

The ACMA Awards, considered the most coveted recognition of the auto component industry, presented to 57 companies for their contribution in the following 13 categories – the Best ACMA Company Of The Year, Excellence in areas such as Technology-Product Innovation, Technology-Process Innovation, Quality and Productivity, Manufacturing, Human Resources, Supplier Development, Export, HSE (Health, Safety and Environment), Small Category Awards, Business Growth, Digitization, Resource Optimization and Make in India.

ACT is a specialised group with the mandate to provide technical support and services to the ACMA members to help them adopt global best practices. ACT’s primary focus is on providing expert guidance to members to improve their manufacturing competitiveness, implementing Zero Defect Quality, New Product Development, improving export capability, enhancing quality standards and increasing productivity and profitability through various specific interventions.

ACT has successfully established world-class shop-floor practices through cluster programs. These clusters have been a popular intervention that aims at creating competitiveness among member-companies for domestic and global markets. ACT also ensures that these programs result in profitable and sustainable improvements.

Commenting on the success of ACT’s role in nurturing the auto component industry, Mr. Nirmal Minda remarked: “Here I like to acknowledge the tremendous contribution of the ACMA Centre of Technology though its cluster programs in transforming companies to be globally competitive. Today, the auto industry is at a point of inflection as it endeavours to meet the changing customer preferences and to be compliant to the increasingly stricter regulatory norms. In order to stay relevant, the Indian auto component industry will have to adopt the latest manufacturing techniques and technologies. We at ACMA are committed to guide and support the industry in this phase of transition, and in fact our annual ACMA Awards presented are a testimony to ACMA’s efforts in helping the industry become competitive. My heartiest congratulations to the winners”.

The main categories of Awards and winners are as follows:

Excellence in HR: Large Category

Gold: Takshu Auto Components Pvt. Ltd., Pune

Silver: Sanjeev Auto Parts Manufacturers Pvt. Ltd., Aurangabad

Excellence in HR: Very Large Category

Gold: Subros Ltd. Unit – 2, Noida

Silver: Spicer India Pvt. Ltd., Satara

Bronze: National Engineering Industries Ltd., Jaipur

Excellence in Export: Very Large Category

Gold: TVS Sundaram Fasteners Ltd., Kanchipuram

Export in Excellence: Large Category

Gold: Orbit Bearings India

Silver: Hi-Tech Gears Ltd. and Hella India

Excellence in HR: Large Category

Gold: Takshu Auto Components Pvt. Ltd., Pune

Silver: Sanjeev Auto Parts Manufacturers Pvt. Ltd., Aurangabad

Export in Excellence: Medium Category

Gold: Delux Bearings Pvt. Ltd., Wadhwan

Silver: Sellowrap Industries Pvt. Ltd., Ggn.