Whether it is greenhouse gases, shorter product development time or solutions for waste heat recovery, TitanX is future-proofing its business through advanced engineering. “We are proud that so many OEMs recently have chosen TitanX for its brand new truck generations. We see that as a proof that the combination of intelligent engineering and efficient production is the right way to go,” says Stefan Nordström, CEO.

TitanX has a unique position in the powertrain cooling industry since it is the only player fully dedicated for commercial vehicles and gensets. This focus helps the company in creating world-class solutions with quality performance for major global truck brands. In eight years, TitanX has grown from three plants carved out from Valeo to a global player with 7 plants which today serves customers in its main markets all over the world.

Cooling the winners

These customers do well, six of the international Truck of the Year winners since 2010 are cooled by TitanX. In North America, Daimler Trucks new generation heavy and medium duty trucks will be cooled by TitanX and the ramp-up to full production has started in its Mexican plant. Another premiere this year was Scania’s New Truck Range, where TitanX provided both engine and oil cooling. The cooling system in these new trucks has been improved to cut fuel consumption to make its customers more profitable.

Technological competence

TitanX understands the customers’ need to meet the challenges of fuel economy demands, emission legislations, cost and an ever increasing demand for safer and more productive trucks. This they must accomplish in a highly competitive market with global competition and ever increasing specialized vehicle configurations. So TitanX knows the importance of constantly keeping the products lighter, smaller and more powerful to support these challenges.

“We must do this in such a way that we keep our total costs low to make it easy for our customers to do business with us. That is why we are putting a high share of our annual sales into developing the cooling technologies for the future and to develop faster and more efficient R&D-processes. We call these efforts advanced engineering” Nordström said.

Dynamic Standardization

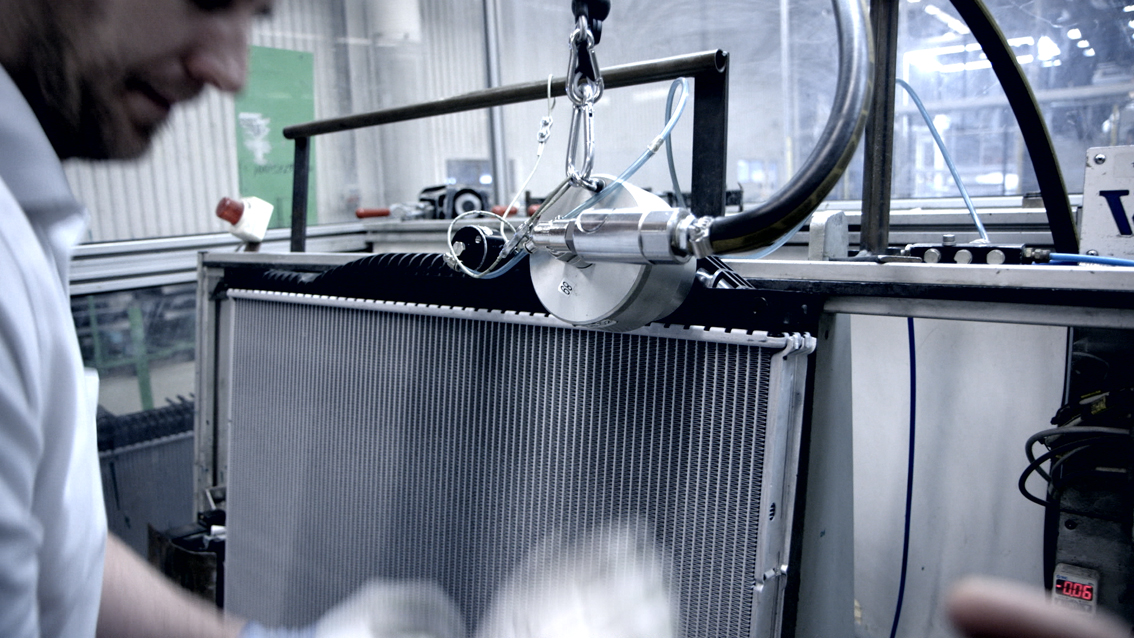

One part of this is Dynamic standardization. Whilst the customers get unique cooling solutions for their trucks or buses, TitanX bases those solutions on its highly standardized heat exchanger components, development methodologies and manufacturing processes. This allows TitanX to bring the benefits of long experience to all of its global customer application needs. In this way the group ensures that the customers get both the right heat exchanger performance and a world-class product quality wherever at TitanX the product is developed and produced.

Another important area is Multiphysics Simulation. TitanX has shown that traditional single destructive phenomena CAE methods are not sufficient to represent the challenges of modern vehicles. With Multiphysics Simulation the product development work becomes faster and more cost efficient, through replacing physical prototypes with complex and effective computer simulations.

Waste Heat Recovery

Yet another element of advanced engineering is Waste Heat Recovery. For a number of years, waste heat recovery has been a project for universities, scientists and long-term planning departments of the industry. TitanX has participated in some of these projects and learned a lot. With the GHG phase 2 legislation in NA, and assuming similar limits in the upcoming EU legislation, TitanX expects to see this technology move out of the laboratory and into the vehicle market.

“This in combination with clarity on the Department of Energy Super Truck 2 program will accelerate the development of WHR systems over the next few years. In this exciting environment, we are pleased to be able to announce that we are involved with multiple OEM projects both here in Europe and in NA to test our prototype heat exchangers in next generation WHR systems,” says Mr. Matt Moore, Vice President Research, Development & Engineering.

Tata Autocomp to be new owners

In mid-August this year TitanX was sold by current owners private equity group EQT and Fouriertransform to Tata AutoComp, a part of the Tata Group in India. The take-over will be during Q4 of this year. TitanX and Tata AutoComp are very complementary to each other and both will benefit from the deal. TitanX gets a long-term, strategic owner who makes it possible to take the next steps in the growth strategy and current structure stays intact. Tata gets a company that fits into its strategy for global growth, which focuses on powertrain cooling, emission regulations and technology. Tata AutoComp also aims to become a global supplier of vehicle components.