New bus plant opened at Oragadam

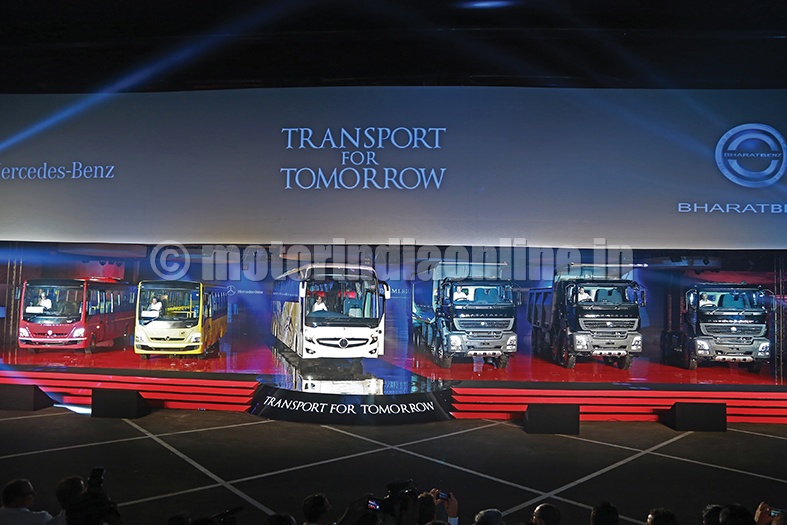

Daimler India Commercial Vehicles Pvt. Ltd. (DICV), a 100 per cent wholly-owned subsidiary of Daimler AG, recently inaugurated its new bus manufacturing facility at Oragadam near Chennai, and unveiled its second wave of products – BharatBenz and Mercedes-Benz buses – as well as a new range of BharatBenz high-power engine tippers and heavy-duty tractors.

Dr. Wolfgang Bernhard, member of the Board of Management responsible for Daimler Trucks and Buses, Mr. Hartmut Schick, Head of Daimler Buses, Mr. Marc Llistosella, Head of Daimler Trucks Asia, Mr. Markus Villinger, Managing Director, Daimler Buses India, Mr. Erich Nesselhauf, Managing Director and CEO, Daimler India Commercial Vehicles, and Mr. Mark Nodder, Chairman and CEO, Wrightbus, were present at the inaugural function at Oragadam.

India is currently a 50,000-unit market for buses which is set to just more than double in five years from now. Not to mention the enormous push from the Government through its initiatives like the JnNurm, which funds State transport undertakings for purchase of high quality buses.

Envisaging the huge potential in the Indian market Daimler has made fresh investments to the extent of Rs. 425 crores at its Oragadam plant. It has already invested around Rs. 4,400 crores at its state-of-the-art integrated truck manufacturing plant, in addition to it, the company has made bus-specific investments in both chassis line and body shop along with its Irish partner Wrightbus.

Wrightbus, a British coach builder and pioneer in low-floor buses, is the partner of Daimler in India for bus and coach bodies and is the first international bus body builder to have a manufacturing set-up in India. Wrightbus has vast experience in building small and midi-sized buses to full-size single deckers, double deckers, articulated buses and Bus Rapid Transit (BRT) vehicles.

The new bus manufacturing plant, constructed within the existing premises of DICV spread across an area of 27.91 acres, will manufacture and assemble buses under two brands – Mercedes-Benz and BharatBenz. The bus plant’s initial capacity of 1,500 units can be expanded to 4,000 units subsequently.

Speaking on the occasion, Dr. Wolfgang Bernhard observed: “We have become firmly established in the Indian market with our BharatBenz brand, despite only operating in the market since 2012. We continue to strengthen our presence in the Indian commercial vehicle market with new products, now also including buses. In doing so, we are opening a new chapter of growth. This investment represents the ongoing pursuit of our strategy of targeted expansion for our global market presence.”

Mr. Hartmut Schick said: “We see enormous potential for growth in the Indian market. For example, we expect the volume of the Indian market for buses weighing over eight tons to more than double by 2020. Our two-brand strategy allows us to offer our customers in the region the right products and services for them.”

Mr. Marc Llistosella stated: “Opening another production facility and introducing a second wave of products in such a short time is another testimony for the strength of our Indian operations. And, in combination with our worldwide FUSO network, this makes the recipe for sustainable growth at Daimler Trucks Asia.”

With the opening of the bus facility, DICV’s is the only Daimler plant worldwide to produce trucks, buses and engines for three brands – Mercedes-Benz, BharatBenz and FUSO – under one roof. The bus chassis are rolled out from the same assembly line as of BharatBenz trucks, as they are technologically similar to the medium-duty BharatBenz trucks. This showcases once more the flexibility of DICV’s assembly lines.

Mercedes-Benz premium inter-city coach

Mercedes Benz coaches are available in India since 2010. Daimler had worked with Sutlej of Punjab as its bus body building partner then and had two coaches – one 12 m and the other 13.7 m. Mercedes was the second international brand to cater to the premium inter-city segment, and with its huge brand pull, it was not a surprise that Mercedes-Benz coaches received fairly good response in the market. Many fleet operators did charge some premium for Mercedes-Benz coaches, claiming that a common man might not be able to afford a travel in Mercedes-Benz car but still can pay for travel by a three-pointed star coach. Mercedes did manage to quickly crack the STU market by winning tenders from many STUs, including the erstwhile APSRTC and KaSRTC.

Addressing all major issues in its earlier product, Mercedes-Benz has now made a comeback and struck again with a new and improved chassis and an all-new body from Wrightbus. The Mercedes Benz coach will now officially be the longest inter-city coach in India at 15 m (CMVR mandates 15 m as the longest overall length for rigid multi-axle vehicles). Owing to the extended length from the previous 13.7 m coach, the chassis now comes with some notable changes like the tag axle being steerable. Apart from this, the addition of disc brakes, improved hydrodynamic retarder and a new polymer fuel tank of capacity 600 L placed just above the rear axle are of high significance.

Mercedes claims its fuel tank positioning will be the best as far as safety is concerned. Following some serious accidents in the recent past, most manufactures are relocating the fuel tank and realigning fuel circuit to safeguard fuel spillage from major accidents. A steerable tag axle is almost mandatory for 15 m coaches, and Mercedes has gone with it. Disc brakes, along with engine brakes and retarder, should definitely offer better braking.

The powertrain is the same as before with power transmitted via a 6-speed manual gear box. It might have been good to offer an automated gear-changing system option as well, which has now become more of a comfort and safety feature in all premium coaches. The premium inter-city coaches now easily touch close to 1,500 km in a single trip with driver comfort and safety becoming more pronounced mainly due to automatic transmission. Though the coaches on display at the launch were fitted with Pirelli tubeless radials, it is understood that the on-road coaches will be available with Michelin radials.

The biggest change, however, will be the bus body. Wrightbus has pioneered a unique light-weight aluminium body structure that provides better vehicle stability and significantly better controls due to a lower center of gravity of the vehicle. Almost the entire superstructure above the space frame is made of ‘Alumnique’, an aluminium alloy which provides considerable weight reduction, yet providing great structural stability.

The coach front facia made of FRP has new looks with a huge star at the centre splitting the grill. The headlights have now moved vertically upwards with the embrasure now inspired from Batman. The looks are now completely new in design from all angles, and it’s indeed a good work by Wrightbus.

With an in-house paint shop, any custom graphics on the coach exterior will be done by 3M inside the plant premises. The seating options can be customized as per the customer choice, up to 49 seats. It was also said that Daimler won’t sell the chassis to customers though the possibility of shell sales for sleeper coaches is not ruled out. The interiors are improved over the previous coach, and the space frame has a higher luggage capacity compared to 11 cu. m. in the previous model. The coach comes with a pantographic swing luggage door that greatly helps when opening in tight spaces.

Mercedes-Benz coaches are now completely backed up by BharatBenz dealers wherever there is no direct Mercedes Benz network. With a lot of promises and new changes, the Mercedes-Benz coach will again be a main contender in the premium Inter-city segment from now on.

BharatBenz ICV buses

It is a planned dual brand strategy by Daimler that the premium bus segment will be catered to by Mercedes-Benz while the economical segment will be addressed by BharatBenz front engine buses. In line with that, BharatBenz has come up with a range of ICV buses. Though one might have expected a full range of buses up to 12 m, BharatBenz showcased a range of ICV buses for school, staff and tourist applications. The chassis is from Fuso Fighter platform a.k.a 914 trucks and is made in the BharatBenz truck chassis line. Though the platform is the same, there has been some serious upgradation and fine-tuning of the chassis to suit the passenger application. The body coming from Wrightbus has a lot of parts sharing with BharatBenz trucks with even the head lamps carried over from it.

The BharatBenz school, staff and tourist buses come in identical lengths of up to 9.8 m and have the same wheel base of 5,300 mm. With lesser front-overhang (FOH), there is no room for passenger entry door here and is possible only in WB and ROH. Chassis suspension has parabolic springs and anti-roll bar with shock absorbers at front and back, which considerably improves the passenger comfort.

The buses, now provided with ABS as a standard fitment which is a step ahead of regulation, fully comply with the bus body code and the school bus code the and will be available only as fully-built option and sold and serviced by the existing BharatBenz dealers. The engine options are 4-cylinder 4-litre Diesel BS III/BS IV-complaint ones developing 140hp and 170hp (for AC). This is by far the highest engine power in its category. Tyres fitted on the display buses were 235 section tubeless radials from Apollo.

The body is again all aluminium made, built at the Wrightbus plant within the DICV premises. Seating options are varied with different lay-outs – 2×2, 2×1 for each application like 26+1 – tourist application, 39+1 – staff application and 49+1 for school application. The emergency exit is given on RHS along with a foldable step which is a good addition and should be a USP. Rear glass is also breakable in case of emergency.

BharatBenz could claim a little premium over the established competition in this segment. The school and staff bus segments are very price sensitive as these are segments where the buses do not earn much for the operator but rather only serve the transportation purpose. So here, the prime buying factor is pricing, which means it should have the lowest cost per seat. Also here, the running mileage of the buses is fairly less, and so the maintenance cost should be fairly less. If BharatBenz addresses these buying factors well, it is certain to replicate its success in the truck segment in buses as well.

New league of trucks

BharatBenz is now an established brand in the Indian CV space and is earning good reputation for its range of products, from 9T to 49T. Now moving up the ladder, BharatBenz is entering high-power premium segments with products for deep mining and ODC transportation, under its Thunderbolt range.

This segment is niche in its way as the volume is relatively small and has till now been catered to only by European brands. Deep mining segments require movement of material from as low as 200 ft and will be operated in arduous terrains for almost 24×7. High engine power is the prime requirement, and so are the trucks, now with 430hp powered engines. Tippers now come with 12 forward speed and 4 reverse speed automated gear box. There are two WB options and with two tipper bodies at 19.5 Cu.m and 32 Cu.m catering to voluminous and bulk load. It is understood that a lion’s share of market has already been captured by these machines, which will be a more common name in the Indian mining transportation space soon.

The BharatBenz Thunderbolt truck range has a high-power puller as well. The 4940T is aimed at transportation of the over dimensional cargo segment. This 400hp puller is designed for transporting heavy-lift project cargo in construction and infrastructure projects that include turbines, heat exchangers, windmill propellers and various industrial equipments. This model will be launched in the market later this year.

Mr. Erich Nesselhauf emphasized at the unveil ceremony: “Since start of production, we have already over 20,000 trucks on Indian roads. This is a reinforcement of the customers’ acceptance of our products. India has a lot of natural resources like coal, iron and other minerals. We expect the Indian tipper industry to grow substantially by 2020. The 3143 will be a game changer in the deep mining segment targeting the most demanding application with a local product.”

Export drive continues

Several passenger car manufacturers use their Indian operations as more of an export hub. Hyundai, Renault Nissan and others cater to huge export markets with cars made in India. The scenario was little different in the CV space as Indian manufacturers were more focused on Indian operations, and the export market was contributing only around 10 per cent of total sales.

In the case of Daimler, from day one it wanted to establish its Indian operations as an export hub. Under the umbrella of Daimler Trucks Asia, DICV and MFTBC (Mitsubishi Fuso Truck and Bus Corporation) have combined their strength to tap into further sales potential. While DICV focuses on the Indian market and countries such as Nepal, which are closely related to the Indian market conditions, MFTBC will service the rising demand in the Asian and African regions with its existing portfolio of FUSO trucks from its Kawasaki plant and the robust FUSO trucks produced at Oragadam.

With Trinidad and Tobago, DICV has now launched 12 export markets like Indonesia, Kenya, Nepal and Tanzania, to name a few. With a clear view on the growth potential in South America, DICV is in getting ready to establish its presence in this region and will continuously add further markets to expand its reach. The bus chassis as well as the heavy-duty mining trucks will continue to expand DICV’s export business, moving forward.