Tata Motors, the undisputed leader in the Indian commercial vehicle industry, has just completed 60 years of exemplary service to the transport sector. Having rolled out its first truck from its manufacturing and engineering facility in Jamshedpur in 1954, Tata Motors has marched on to become the outright numero uno in the truck and bus space for over six decades and also maintain its dominance amidst intense competition from both domestic and global OEMs, evolving customer demands, changing market conditions and other challenges.

Set up in 1945, Tata Motors’ Jamshedpur plant started with manufacturing steam locomotives before foraying into truck manufacturing, bringing the global trucking technology to India nine years later. Since then, the Jamshedpur plant has been modernized and consistently equipped, particularly intensively in the last decade, with state-of-the-art equipment and assembly lines to produce a truck every five minutes. The facility assembles over 200 Tata Motors medium and heavy commercial (M&HCV) models, including the path-breaking Prima world truck. It also houses engineering centres to conduct truck testing in different climatic conditions and on varied surfaces, including dense urban centres, all of which operate under distinct set of rules and regulations governing commercial vehicle operations. The facility crossed a major milestone last year when it rolled out its two-millionth commercial vehicle.

As a development and manufacturing hub for its M&HCVs, Tata Motors’ Jamshedpur engineering research centre is not only capable of carrying out complex vehicle design and integration of the company’s current and future trucks but also developing complex intelligent electronic control systems for next-generation trucks, cabins, multi-axle trucks, tractor-trailers and tippers as well as application vehicles like mixers and tankers for both civilian and defence customers. The facility is also capable of manufacturing trucks compliant to the EURO VI or BS VI emission norms. Tata Motors also conducts driver training programs at the venue to impart knowledge of truck operations, for better road safety and overall vehicle performance.

The world-class Engine Factory manufactures the Tata 697/497 naturally aspirated and turbo charged engines, with a capacity of supplying upto 300 engines per day

Addressing a media delegation that visited the Jamshedpur facility at the company invitation to commemorate its 60 years of truck manufacturing, Mr. Ravindra Pisharody, Executive Director, Commercial Vehicles Business Unit (CVBU), Tata Motors, said: “We at Tata Motors are proud to have achieved yet another trucking milestone of 60 years of manufacturing excellence at our plant here in Jamshedpur. From the very beginning, Tata Motors Jamshedpur has led the transformation in the Indian commercial vehicles space, setting benchmarks through the introduction of class-leading trucks, with the most relevant global technologies, incorporating flexibility to develop and manage our current and future portfolio, with speed and in line with the varied market requirements. With world-class quality manufacturing and engineering programs here in Jamshedpur, it is in our continuous endeavour is to remain the most preferred trucking brand.”

Dr. AK Jindal, Head, Engineering Research Centre (ERC), CVBU, Tata Motors, said: “Our engineering teams at Tata Motors work closely with all stakeholders in developing and successfully deploying various technologies for broad spectrum of commercial vehicles that enable connectivity, safety and better fuel economy, along with optimal vehicle performance. Given our widest portfolio of medium and heavy commercial vehicles, which has been developed based on our deep understanding of customer needs and usage patterns, we at Tata Motors continuously strive to develop and integrate new and relevant vehicular technologies, offering best-in-class value proposition. Needless to say, integration of these new technologies is backed by a strong service network.”

Mr. Ajoy Lall, Head, Jamshedpur Plant, commented: “From Tata Nagar to steam locomotives to road rollers to Prima trucks, we continue our pioneering spirit. The story of Jamshedpur in many ways has been the story of India’s trucking industry. At Tata Motors, we have constantly redefined ourselves, remaining contemporary in changing market landscapes and upgrading our technology in the process”.

In addition to driving the lives of thousands of customers who operate its trucks, Tata Motors has also laid focus on protecting the environment with a range of sustainable solutions.  “As Tata Motors products touch the lives of a large number of people beyond the businesses we cater to, we have developed the widest product portfolio of alternate fuel vehicles, hybrids as well as electric vehicles contributing to improving the environment as well as class leading products like Prima and Ultra family improving driver comfort and safety”, added Dr. Jindal.

“As Tata Motors products touch the lives of a large number of people beyond the businesses we cater to, we have developed the widest product portfolio of alternate fuel vehicles, hybrids as well as electric vehicles contributing to improving the environment as well as class leading products like Prima and Ultra family improving driver comfort and safety”, added Dr. Jindal.

Working towards developing multiple new platforms, Tata Motors also co-operates with all its associated stakeholders to improve the performance and reliability of its existing offerings, proactively taking steps to remain the most preferred brand in the CV space. Having led technological shifts in the Indian CV market, such as standardising radial tyres and offering automatic transmission in tippers, the company has forged ahead through its HORIZONEXT initiative, a four-pronged customer-focused strategy aimed at providing the best customer experience from best vehicle experience to superlative purchase experience, followed by technology-intense aftermarket service support.

Technology-focused approach

Tata Motors has adopted a three horizon technology roadmap to enhance its product offering, with emphasis on research and innovation, integrated electronics architecture and CO2 reduction. Based on this roadmap, the company has developed a series of products in the M&HCV space which were showcased earlier this year at Auto Expo in Delhi.

Over the last decade or so, Tata Motors has driven the industry forward by bringing globally-used and advanced technology to India. With a view to improving environment-friendliness and safety of vehicles, concepts like ABS, electronic stability control in tractors and engines with emission compliance through EGR and SCR were introduced, while sophistications such as next-gen cabins with ergo pack, air-conditioning, keyless entry, electronic instrument cluster, pneumatically-suspended seats, music system, adjustable telescopic steering, clutch booster for clutch pedal assistance, advanced HVAC system and light intensity control were offered for superior driver comfort.

The cab and cowl assembly line operates with high level of automation employing extremely precise robots from ABB.

The line as a capacity to produce 84 cabs per shift which is equal to one cab for every four-and-half minutes

The market leader has also spearheaded the creation of new segments within the M&HCV space with its modular chassis frame and cabin in Prima, lift axle in LPT 3118 – 8×2 vehicle, twin speed rear axle, tandem and parabolic bogie suspension, hub reduction rear axle and single reduction tandem rear axle, among others.

Apart from being India’s largest commercial vehicle player, Tata Motors has forayed into many markets across the globe over the last few years, testifying its globally-competitive product range and manufacturing capabilities. The company starts by ensuring quality at each level of operation, the Jamshedpur facility being at the forefront in this regard. With the facility being able to cater to CVs with payloads ranging from 7 to 49 tonnes, over 20 Tata Motors CV models are currently exported and assembled based on the specific quality-led standards and processes.

Sales and service initiatives

The cab & cowl factory is equipped with an Automated Centralized Paint Shop with a provision for metallic painting and Centralized Trim Lines, which help streamline the logistics flow. The Plant also houses a shower testing facility in vehicle dispatch area. The facility’s NABL-accredited

Metrology Lab houses one of the biggest horizontal dual arm coordinate measuring machines in the country which is 6.5 m long

Besides ensuring a balanced expansion of its sales and service reach, Tata Motors is adopting several initiatives to drive efficiencies and manage customer relations better through the sales and service channel as well as at various customer touch points. It has undertaken unique measures to ensure the right qualities in its sales workforce which forms one of the most important links in the value chain.

The initiatives include:

‘DRONA’ for sales force:

• Rich training content by specialists

• High quality specialized trainers (48 Dronas) – for each segment / service

• Product & soft skills training for the dealership sales team – 2-day classroom sessions with role plays

• Dealer Sales Executive (DSE) ‘on the job’ coaching for efficiency and effectiveness

‘LEAP’ (Learn & Engage for Augmenting Profitability) for channel partners:

• Premium training program conducted by eminent management consultants along with plant visits

• Six programs completed at different plant locations covering 120+ dealer principals

The main assembly line rolls out one truck every 5 minutes. Two other lines are dedicated to the Prima range, Multi-axle, special purpose vehicles and for meeting the requirements of the defence sector

HR tools for employee engagement for dealers:

• Regular training programs for HR teams at dealerships

eLearning:

• To train TSMs on products and processes

• Learnings captured through learning management system

• Trainees evaluated pre- and post-training to measure effectiveness

• eLearning to become a standard practice for all new product/process launches

• DRONAs to start using eLearning as a tool for effectiveness measurement

In addition to its refreshing efforts to strengthen its sales team, Tata Motors has also been placing unwavering focus on consistency in service by offering best-in-class quality solutions to its customers. The ‘Power of 5’ concept which includes Tata Alert, Tata FleetMan, Triple Benefit Insurance, 4-year warranty and Extended Service Interval is an innovative offering from the company with the aim of strengthening its support to, and engagement with customers. These services are backed by a Tata service touch-point every 50 km on all major highways in the country, in addition to first-time-ever schemes such as ‘Tata Delight’, a loyalty program for retail customers and ‘Tata Emperor’ for large key customers.

CSR

With 603 acres at Jamshedpur for manufacturing, engineering and support services, Tata Motors has a township covering 1,250 acres, housing residential quarters, hospitals and schools. While making technological, product and service advancements, the plant has been deeply committed to the community within which it operates, working closely with various NGOs. It has pioneered initiatives in areas like health, education, livelihood and environment which have resulted in significant progress in the community and social forestry, sustainable development of wastelands, road construction, rural health and education, development of rural industries, water supply and family planning.

————————————-

|

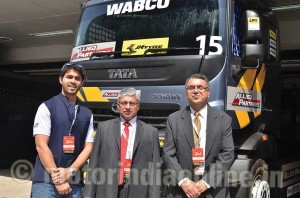

Hearty congratulations to Tata Motors on achieving this significant milestone. Eaton is indeed very proud to be associated with this legendary organization, which is also the undisputed leader in the Indian CV segment for the last 60 years. We enjoy a very strategic relationship when it comes to offering safe, reliable and efficient power management solutions through our industry leading drive train products. Our engagement extends right from passenger cars to heavy commercial vehicles and from domestic to export markets. With Tata Motors, Eaton sees an opportunity to offer its entire advance product range covering engine valves & valve actuations, superchargers, torque control products, commercial vehicle transmissions, hybrid solutions and fuel emission control products. A few of our engagements worth mentioning at this juncture are: • India’s first CNG hybrid bus • Heavy duty transmission for world truck program & specialized application • Tata trucks at India’s first truck racing event were geared with Eaton transmissions • Eaton torque management solution (differential lockers) • Engine air management solutions We wish Tata Motors many more successes in the days to come. – Mr. Krishnakumar Srinivasan, President – Vehicle Group, Asia Pacific Region, Eaton |

|

Tata Motors pioneered the commercial vehicles revolution in India 60 years ago and continues to lead this segment today. The first Tata Motors trucks and buses have been powered by Bosch (then Mico – Bosch) and still continue to do so. We are proud of our partnership with Tata Motors which has strengthened over the last six decades, and we feel ourselves part of the extended Tata Motors family which stood the tests of time. Our two organizations share common values. Our partnership is based on trust and mutual respect, and we are passionately working together to bring affordable and innovative products and solutions for Indian automotive customers of commercial vehicles and passenger cars. While congratulating Tata Motors, we wish them greater success in the exciting times ahead, both in Indian and global markets where they are making strong footprints. – Dr. Steffen Berns, Managing Director, Bosch Ltd. |

|

Jost made its entry into the Indian market with direct supplies from its China plant in 2005. Local production and billing commenced from July 2008. Working with Tata Motors has always been a seamless experience right from negotiations to supplies. Tata Motors’ approach to its suppliers’ concerns are commendable. The entire hierarchy from the plant head to the buyer is very much approachable and solutions are offered in the quickest possible time. Jost supplies its fabricated 20T version of the fifth wheel couplings for truck-tractors upto 40T and 28T version for truck-tractors upto 49T. More value addition in terms of assemblies of fifth wheels, mounting plate and sub-structures have also ensured a win-win situation for both Tata Motors and Jost India. Jost also has an advanced line of products like hydraulic wet kits, trailer axles / suspensions and automated fifth wheels that could be supplied anytime Indian OEMs like Tata Motors wish to. Being a supplier meeting Tata Motors’ 100 per cent requirement of their Jamshedpur plant, it is a big responsibility to ensure uninterrupted supply, and we feel proud to be associated with the market leader in India and hope to grow along with them. |

|

There are very few manufacturers who have been successful over a period of time. In the current scenario, with the world’s leading vehicle manufacturers having entered India and striving to garner a major share in the Indian commercial vehicle market, Tata Motors has done exceedingly well in maintaining its dominant position. The new entrants adopt different strategies like offering product at a lower prices, keeping a greater focus on one particular segment, etc. We feel that the Indian commercial vehicle customers are more mature than most people acknowledge. Such short-term strategies have not paid dividends to the newer entrants, but it is the established manufacturers such as Tata Motors who, over the years of experience, truly know the most appropriate way forward. VST being a dealer for Tata Motors since mid-1950s, its relationship with the group is one of pride and admiration. When it comes to handling the dealership personnel, solving customer issues, building trust in the franchise, maintaining a healthy relationship as partners, VST would rate Tata Motors among the top brands in the country that one should be associated with. Tata Motors now celebrates 60 years of their Jamshedpur plant. To manage a manufacturing unit and to successfully adapt and change with the times and still be ‘world class’ and ‘market leader’ is truly laudable. We, at the VST Group, would like to congratulate Tata Motors, and look forward to many more decades of a truly inspirational partnership. – Mr. Arun Surendra, Managing Director, VST Motors |

|

The Pune-based Tata AutoComp Systems Ltd. supports Tata Motors in many ways. While most of its plants in Pune supply to the Passenger Vehicle business, Tata Motors is the anchor customer of Tata AutoComp, and that is the reason why it supports Tata Motors by setting up plants very close to its manufacturing facilities. In Jamshedpur, two of Tata AutoComp’s business units have plants within the premises of the Tata Motors plant. Tata Toyo Radiator supplies engine cooling solutions like radiators, fan motors, condensers and inter coolers as an entire engine cooling module. Tata AutoComp Composites Division supplies various components made from glass fibre-reinforced sheet moulded composites. The parts include the bumper, stepper, front panel engine hood and several other parts. Tata AutoComp also has dedicated plants at Pantnagar where it supports the Tata Motors Ace platform with engine cooling solutions, components made from glass fibre-reinforced sheet moulded composites, plastic parts, rear view mirrors, gear shifters, parking brake levers, sheet metal parts and aggregates, as well as many other parts. Besides setting up dedicated plants for specific components, Tata Auto has helped Tata Motors carve out niches in the market place through product innovation. One of its business units, Tata AutoComp Hendrickson Suspensions (THSL), is in the business of manufacturing high-end suspension systems for heavy commercial vehicles. Tata Motors has been the game-changer in the Indian CV industry; one among them is to create the 8×2 truck segment. THSL is the first to participate in this endeavour with their lift axle air suspension system. Even after six years of introduction, Tata Motors continues to be the market leader in the segment through the model LPT 3118. This has also enabled it to be another first by creating the 37-ton truck segment and THSL continues to be the partner in development of lift axle air suspension system. THSL’s another major contribution to the Tata Motors endeavour to introduce world class solutions is the “6 rod Bogie suspension system” for Prima tractors. Now THSL is working on bringing in a further reliable system rubber-metal suspension system without a leaf spring. This system uses fabricated beam as the main load bearing member and rubber springs as the member absorbing road shocks. Tata AutoComp recently formed two new joint ventures – Magna International which will offer high-end seating systems for commercial vehicles, and KATCON Global to offer Euro 5 and Euro 6 compatible exhaust system and emission after-treatment solutions. |

|

Tata AutoComp Hendrickson Suspensions Pvt. Ltd. (THSL), a JV between TACO & Hendrickson and the global leader in suspension technology, provides the technology leadership in advance suspension application for the medium & heavy commercial vehicle segment. THSL has applied this knowledge to bring breakthrough solutions to Indian OEMs. Tata Motors Ltd. (TML) has been the game-changer in the Indian CV industry. One such initiative is to create the 8×2 truck segment. THSL was the first to participate in this endeavour with their lift axle air suspension system. Even after six years of introduction, TML continues to be the market leader in the segment through the LPT 3118 model. This has also enabled TML to be another first by creating the 37-ton truck segment, and THSL continues to be the partner in the development of the lift axle air suspension system. THSL’s another major contribution to TML’s endeavour to introduce world class solutions is the “6 rod bogie suspension system” for PRIMA tractors. Now THSL is working on bringing in a further reliable rubber-metal suspension system without a leaf spring. This system uses fabricated beam as the main load-bearing member and rubber springs as the member absorbing road shocks. Mr. Sanjay Sinha, CEO, THSL, conveys his best wishes to Tata Motors to keep the leadership position in the commercial vehicle industry and to enrich the industry with innovative products and many more firsts. |

|

On behalf of the entire team of SVLL, I extend my heartiest congratulations to Tata Motors for completing 60 glorious years of success. We have been associated with Tata Motors for many years now. In fact, the very first truck that rolled out in 1988 before SVLL was formally incorporated was a Tata 1616. Since then, all the major fleet orders have been placed with Tata Motors because we believe in their technologically superior vehicles and their exceptional customer services. Almost 60 per cent of the total fleet owned by SVLL is Tata branded. Two of our record orders of 1,111 and 1,314 M&HCV trucks were placed with Tata Motors in 2011 and 2012 respectively. These orders have gone down in the history of India, with the order of 1,111 vehicles recognized by the Limca Book of National Records as ‘the largest such single booking by a private company’. With their commitment and sincerity, they have always striven to make on-time delivery. Tata Motors is truly a pioneer in the Indian transport industry. Our association with them has been a real honour, and we value each and every transaction and deal with them. We wish them all the success for many years to come and hope to continue doing business with them in the future. – Mr. Deepak Baid, Director, SVLL. |

|

Dassault Systèmes has had an enduring and deep engagement with Tata Motors across a decade-and-a-half. Dassault Systèmes is a key software partner to Tata Motors and its solutions have helped improve product development cycles, productivity and quality. The company is upbeat about Tata Motors’ Horizonext strategy, and as an important player in their eco-system, believes that this will drive the future growth of the company. Tata Motors deploys Dassault Systèmes solutions in the areas of new product development, engineering, styling, simulation and creating and managing a digital factory. Dassault Systèmes is a 3D Experience company that provides business and people with virtual universes to imagine sustainable innovations. Its world-leading solutions transform the way products are designed, produced and supported. Dassault Systèmes’ collaborative solutions foster social innovation, expanding possibilities for the virtual world to improve the real world. – Dr. Chandan Chowdhury, Managing Director – India, Dassault Systèmes |

|

Our association with Tata Motors has been a long and fruitful one. We have supplied a range of components to Tata Motors, including instrument clusters for some of the group’s flagship models, and look forward to being a part of their future projects. We extend our heartiest compliments to Tata Motors on having completed 60 years of remarkable service to the transport industry, and wish them many more years of success. – Dr. Christian Neumann, Head BU Commercial Vehicles and Aftermarket, Continental |

|

I am not so fortunate to be associated with Tata Motors as my two sons, Gurjit Singh and Gurprit Singh Randhawa, are. It was an afternoon in Pune which was hosting the All India Dealers Meet in 2007. They fortunately met Tata’s Supremo, Mr. Ratan Tata and found him to be a ‘Trimurti’ of Humility, Compassion and Empathy. Despite his busy schedule, he preferred to come along with his team to see the first-ever ‘Food & Vegetable Van’ body designed, developed and built by us on the chassis of Tata Ace for the first time. Till today, my sons are wonder struck about Mr. Tata’s eye for detailing, mode of enquiry and appreciation of innovation as well as young and upcoming entrepreneurs…………” As for Tata Motors, the group is doing well globally along with its associates. We wish continuous growth for ever for Tata Motors. – Mr. M.S. Randhawa, Managing Director, Randhawa Automobile Engineering Pvt. Ltd., Navi Mumbai |

|

We heartily congratulate Tata Motors for being the pioneer in the Indian automobile industry for 60 years. Tata Motors can hardly be called a company. It’s an institution in the Indian business community. It has not only created value for its shareholders but has created several business families in its network of dealers, customers and vendors. We have been fortunate enough to be part of Tata Motors’ history since its inception. Our family first bought a Tata bus in 1960, and we ran a fleet of about 200 buses in that era. We have also been dealers of Tata Motors since 1962. Today a large part of our success as entrepreneurs can be attributed to Tata Motors, and we can proudly say that we are fully enjoying the benefits of the company by being its customer owning over 1,500 Tata commercial vehicles, a vendor transporting Tata vehicles from its factories to various dealerships, as well as a dealer in Muzaffarpur, Bihar. – Mr. Tirtharaj Himatsingka, Director, Ideal Movers |

|

Tata Motors has been the pioneer in the CV industry. They have made distances smaller and brought the nation together. It is their endeavor that allows us to enjoy the great treats of India at our doorstep. May the next 60 years be as fruitful to our great company and everyone associated with them. “Tata Motors – A nation builder” – Mr. Sanjay Bhandari, Managing Director, Bhandari Automobiles Pvt. Ltd. |

|

With the evolution of the truck industry in India and the ever-increasing demand from the end-user on account of performance, we developed a new concept for the Indian market for pinions. Based on our experience, we worked jointly with the Operation & Design team of Tata Motors (ERC) and Tata Motors Driveline in introducing a matched preset bearing assembly (pinion pac) which has a very closely controlled bench endplay. The visible advantages are: • Elimination of the setting process at the customer end • Ready to mount bearing assembly • Lower assembly cost in production due to reduced assembly time as bearing is pre-set. • Skilled manpower not required as setting is eliminated. • Elimination of spacer inventory carrying cost and administration charges. • Elimination of scrap – broken unusable spacers • Improved field performance as Pinion Class bearings with enhanced profiles Earlier, in April last, we rolled out the 1,00,000th pinion pac assembly for Tata Motors and are presently working on the other innovation areas. |

|

We sincerely thank the Tata Motors team and appreciate the efforts to establish trailer manufacturing in India. We are associated with Tata Motors since 2006 and are developing the trailer as per the Indian road condition for various applications. We together have changed our perception of the traditional trailer being used in India for greater safety, high speed and very economical mileage. Trailers based on the proven technical design and evolved over a period of time have proved their worth even in adverse road conditions. Now the Tata DLT trailers have become the benchmark for quality and operational excellence. Tata DLT has its own design centre and state-of-art manufacturing facility with the highest manufacturing capacity in India. Because of our joint efforts, now more than 10,000 trailers of Tata DLT are plying in different regions without any problem. – Mr. Rajeev Batra, Chief Operating Officer, Tata International DLT Pvt. Ltd. |

|

ICAT has been closely associated with Tata Motors since inception. The relationship between the two has grown immensely over the years, with Tata Motors being one of the leading customers of ICAT. The company congratulates Tata Motors on its successfully completing 60 years of operation, and hopes to see many more such milestones to be achieved in the coming years. – Mr. Pawan Thakur, Manager, PMG Dept., International Centre for Automotive Technology (ICAT) |

Top priority for meeting full customer needs at any cost R. Ramakrishnan

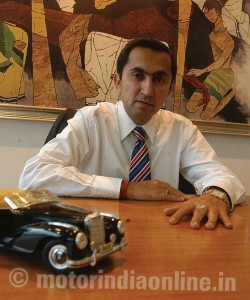

Interview with Mr. R. Ramakrishnan, Sr. Vice President (Commercial), CVBU, Tata Motors

Tata Motors has completed 60 years in the transport industry. To begin with, can you throw some light on your working career with the company?

This is my 30th year at Tata Motors. I joined the company as a Graduate Engineer Trainee in 1985 in what was then the Excavator Division. After seven years there, I moved to the Automobile Division in 1992 and spent some time in south India as sub-regional manager and then regional manager, responsible for Tamil Nadu and Kerala. Then I spent an year at our Pune plant before moving to Mumbai as Product Manager for medium and heavy trucks. Till 2003 I was in Mumbai. During the period we started the world truck project. We also established a New Product Introduction (NPI) division in the company since it was fully realised that products were the base on which we should build our future. Therefore, it was important to carve out a separate division which managed from ‘concept to cash’ for new products. Till 2009 I was heading the medium and heavy trucks division for NPI and then became the Head for Commercial Vehicles. About a year later, I was asked to look after the Passenger Car Business and then came back to CVs.

This is my 30th year at Tata Motors. I joined the company as a Graduate Engineer Trainee in 1985 in what was then the Excavator Division. After seven years there, I moved to the Automobile Division in 1992 and spent some time in south India as sub-regional manager and then regional manager, responsible for Tamil Nadu and Kerala. Then I spent an year at our Pune plant before moving to Mumbai as Product Manager for medium and heavy trucks. Till 2003 I was in Mumbai. During the period we started the world truck project. We also established a New Product Introduction (NPI) division in the company since it was fully realised that products were the base on which we should build our future. Therefore, it was important to carve out a separate division which managed from ‘concept to cash’ for new products. Till 2009 I was heading the medium and heavy trucks division for NPI and then became the Head for Commercial Vehicles. About a year later, I was asked to look after the Passenger Car Business and then came back to CVs.

Tata Motors has kept its market share intact in the last decade despite growing competition and changing market conditions. How have you managed to do it?

One of the main triggers was the significant loss we made in 2001-02 and that was when we said ‘we will not let this happen to us again’. We gave ourselves a ten-year horizon to plan ahead rather than just plan for a year or two, and also started looking at markets around the globe. We learnt from each market. Europe, particularly Germany, and the US were quite different from ours, whereas markets like Brazil and China were closer to us in terms of origin but had moved ahead in product evolution, customer types and so on.

In terms of products, until then we were looking at the Indian market and offering what our customers wanted, which was by and large good enough. But the apprehension about ensuing competition made us think as to where will we be when it does come. We also thought: ‘why can’t we make vehicles for other global markets?’. We did export around 10 per cent of our total business, but then we were also thinking of the developed markets.

The testing area includes engine performance, endurance and emission testing, indoor and outdoor vehicle testing, NVH (Noise, Vibration, Harshness) testing. It also houses advanced facilities such as 8-Poster machine for durability testing at component/sub-system/vehicle levels.

Chassis Dyno for vehicle performance and powertrain endurance testing.

We went out and met our customers to understand their experiences in using our products and the other products available in the market as well – ‘whether they use our vehicle as such or they modify things, and whether can we save them the trouble by modifying them ourselves; what are the pain points of customers and how can we address them?’ We discovered that while we knew certain things, we also had a lot to learn from them. It is not a homogenous market – a customer in Delhi is different from the one in Punjab or Namakkal, and even within a State like Tamil Nadu, a transporter in Chennai is different from the one in Namakkal. So it would be incorrect on our part to think that one kind of product will be good enough for all customers and all applications.

Following this, we studied the different applications for which trucks are put. This led to a plethora of things to consider. We looked at the driver who spends most of his life in the truck, and we also looked at the transporter. We got some clear insights and made an assessment: ‘Five years hence, what will consigners want? Five years hence, if we have to protect our market share or grow it, what should we be doing and how should we address these customer needs. What should we do if the market changes and if we want to sell products outside India. With all this, we were no longer looking at minor improvements but were looking at a very big leap.

Following this, we studied the different applications for which trucks are put. This led to a plethora of things to consider. We looked at the driver who spends most of his life in the truck, and we also looked at the transporter. We got some clear insights and made an assessment: ‘Five years hence, what will consigners want? Five years hence, if we have to protect our market share or grow it, what should we be doing and how should we address these customer needs. What should we do if the market changes and if we want to sell products outside India. With all this, we were no longer looking at minor improvements but were looking at a very big leap.

Can we look at it as a shift from short-term planning towards preparing for the long term?

We were looking at the long term and thought: ‘If we want a particular kind of product five years down the line, when and how should we start working for it. In the M&HCV space, for instance, it became quite evident that customers who were evolving with companies that transport goods becoming more demanding and drivers evolving too. Both the consigner and the transporter want the lowest cost of operation, while the driver wants to feel comfortable while driving. Hence we had to do a number of things to cater to all their needs.

We listed down several features, and in order to verify our direction, we went back to our customers and checked if those were what they wanted. We received a variety of responses and translated them into specifications and design, setting targets for each dimension. We were able to do all these under the environment of the NPI division, and the Prima is one of the products which was born as a result.

The on-road test track includes high speed tracks, torture tracks, water trough and gradient tracks, where vehicles are put through severe testing

How important was the introduction of the Prima for Tata Motors?

The Prima was a kind of shocker for the Indian market and also for the company. It was a huge distance ahead from where we were and what the customers used to seeing in India. It has taken time for them to understand why we are doing it and what it means. But customers who have used it are absolutely thrilled. We were not worried about the time taken by the market, because we were expecting it to happen and did not look for sales overnight. But the fact is that we are now prepared for at least another 15 to 20 years. We can easily come up with two to three more facelifts for the cabin. Most of the other aggregates were anyway being used on our standard trucks, so the investment was already in place for us.

The Prima was a quantum leap in technology, manufacturing quality and also the way our sales people addressed the customer needs. It was a big leap across the value-chain, and it helped trigger off a few more changes at our end – like the Ultra ICV platform which is also built on a modular philosophy, keeping the driver, operator and various applications in mind. Also in buses we took the world-class route by taking over companies like Hispano of Spain and collaborating with companies like Marcolpolo of Brazil and, as a result, we have a range of buses which represent a leap in terms of comfort, safety, NVH, etc.

The whole Prima project helped the company at large and also the market and the industry to feel confident that something like it could be done, because till then nobody had ventured forward. As a leader of commercial vehicles in the country, we took those steps which also encouraged the others in the industry to come forward. There is a whole supply chain that was developed to cater to these needs by upgrading their technology, quality, etc. What we have sparked off is an evolution in the whole industry.

From a customer perspective, there is a gradual shift from the ‘brand loyal’ customers to more rational ones. What are your thoughts?

The first generation of transporters were mostly those who started off as cleaners or drivers and then became owners and fleet operators. They had a very deep attachment and loyalty to the truck brand, and for them a truck is not just a truck, it’s not just a source of living, it’s a relationship. They look at their business as much more than just a business, they see it as something which made them what they are in life. So, the dealer and the company that helped them buy their first vehicle stood by them and helped them in difficult times. This means a lot to them – the bond is very strong. Yes, there is some amount of rationality in their decisions, but there is also a lot of faith and trust reposed in the company and the dealer.

The second generation customers have a bit of both (brand loyalty and rationality) because they have started as transporters. They are more rational and balanced in their decision-making and look at their business needs, since the consigners, who are their customers, have become more demanding. The third generation transporters, many of whom are educated abroad, operate as 3PL companies. Most of their customers are multinational clients whose expectations from a transporter and transportation are very different and very demanding. They expect the goods to reach at the given time and, if not, the transporter is penalized. The third generation owners do respect the brand loyalty of their fathers and grandfathers but run the business more on rationality.

Tata Motors is geared up for this change, not just because of our product range but also in terms of our preparedness on the sales and service front. Our service standards have gone up and our discussions with customers are mutually beneficial. Earlier, a dealer sales executive was like a courier guy, just delivering some documents. But today he has to sit and discuss a lot of issues with the customer to understand and satisfy his needs. Sales and service has changed a lot in the last decade, and we have measured up well to meet the customer requirements.

——————————————-

|

I take this opportunity to congratulate the entire Tata Motors family on completing 60 glorious years of the plant in Jamshedpur and wish them a prosperous future ahead. My career in Tata Motors Ltd. spanned for 37 years, from 1969 to 2006. I still remember my first day at Tata Motors, Pune, as a Graduate Trainee on February 9, 1969. the group was then the largest conglomerate in India. I stood there with mixed feelings of pride, fear and energy to achieve the tasks assigned to me. Today, after 45 years of that first day in Tata Motors, I thank the company for helping me grow to become the person I am. Having joined Tata Motors, Pune, in its formative years, I was designated to its green field projects. The years to follow saw development and addition of new aggregates – from the engine, gear box and sheet metal parts to the final vehicle assembly. Finally, as the production in-charge and a senior member of the management team, I was involved in various projects of the company, from the coveted ‘Indica Project’ to the special-purpose vehicles used for passenger and goods transport. It was during this period that I was also responsible for setting up the 4th plant at Dharwad in 2001 and eventually retired as the Head of Special Purpose Vehicles & Buses from the World Trade Center Office in Mumbai. Inspired by the knowledge accumulated during my years with Tata Motors, after retirement, in January 2006, I took up the task of setting up an organized unit to cater to the design, development and manufacturing needs of transport equipment and truck applications under the name “Transport Solutions India”. At TSI we manufacture trailers, tippers and bodies for logistics companies and truck OEMs. TSI today has joint ventures with LOHR (France) for vehicle carriers, HLM (the Netherlands) for reefer container bodies, and MOSOLF GmbH (Germany) for finished vehicle outbound logistics. To serve the country’s transport system better, TSI is regularly bringing new technologies and transportation solutions both from within and without. We are now present in India with manufacturing plants in Pune, Chennai and Puducherry for TSI-LOHR-HLM, Automotive Coaches and Components Ltd. and PL Haulwel Trailers respectively. I personally wish all my fellow colleagues, current and former employees, supplier partners, customers and all at Tata Motors the very best to fulfil the dreams of Jamshedji Tata, JRD Tata and the 100-year vision of Ratan Tata and Cyrus Mistry. – Mr. V.K. Singh, Managing Director, TSI Group of Companies |

|

Our journey with Tata Motors over the last 50 years has been extremely congenial and successful. We have grown together and played a significant role in effectively enhancing the transportation business in the urban and rural markets in Gujarat, Rajasthan, Punjab and now in Delhi. We have always believed in working as a Team in line with the defined policies and responsibilities entrusted to us by Tata Motors. We have had a great and splendid association with Tata Motors and do look toward to cherishing our togetherness in letter and spirit in the days ahead. – Mr. Jayant Nanda, MD, Cargo Motors Pvt. Ltd. |

|

I am simply rejoicing at the very thought that Tata Motors completes 60 years of its core existence in the business of trucks & buses. India’s CV market was largely represented by TML in the pre-liberalisation era, thereby leaving a distinct mark about India’s independent capability in the early automobile terrain post Independence. Tata Motors is very close to my heart. It was Tata Motors that extended to me a platform, allowing me to showcase my organization’s credentials in the field of Chemical Etching for automobiles, thereby opening a new gateway for us into the automobile domain in India. As TML enters its 60th year of its presence in the CV market, it coincidently marks our 25 years of association with it. This journey with TML has indeed been a learning curve of Tests & Triumphs, at times even making the impossible possible for texture applications onto contoured profiled surfaces. On this important occasion, I extend my heartiest congratulations to the TML Management & Team for carving out vehicles which reflect Indianess in every aspect, and trust this is just the beginning of many more milestones to be achieved by TML. We stand committed towards TML as they embark on their next platinum path. – Mr. Anand Naresh Motwani, MD, Eschmann Textures India Pvt. Ltd. |

|

We are very proud and glad to inform you that we, Sunil Transport, are the privileged customer of Tata Motors for the last several decades. We have entered the 50th year of our dedicated service, and from the beginning we have used only Tata commercial vehicles. Sunil Transport is the pioneer in transportation of liquid chemicals on long routes, and we have regular service from Gujarat to Assam. We are able to meet our customers’ requirements with Tata Motors’ vast network all over India, easy availability of spare parts, prompt after-sales service and AMC. This helps our vehicles to ply on roads safety and deliver goods on time. Also, as Tata vehicles can be easily sold, it helps us upgrade our fleet regularly. They always maintain their commitment to their loyal customers, and we are very proud of our long association with them and wish them all success in their future endeavours. |

————————————

We are always one step ahead when it comes to the Indian market: Vinod Sahay

Interview with Mr. Vinod Sahay, Head – Sales and Marketing, M&HCVs, Tata Motors

With sentiments improving after the Lok Sabha elections, do we see a revival in the medium and heavy commercial vehicle market?

Things are getting better now, and we are definitely seeing a big change post the elections, with sentiments becoming very positive. The new stable government at the Centre and the mandate it has proposed has turned the outlook positive for our customers and in turn their customers, apart from the larger companies and the small and medium enterprises. We are already seeing growth in some segments like transport of cement and coal where the situation is far better than before. We expect the same to happen in other sectors like mining and infrastructure as well.

The large fleet operators replace at least 30 to 40 trucks every year, but due to the recession it has not happened for the last 2½ years as most of them have postponed their purchase. Because of the positive sentiments, things are now changing with the large operators going in for new trucks to replace the old ones.

Some say it might take nine months for full industry revival, while some optimists say it will happen in three months. One thing which is clear is that the slowdown is definitely behind us and we are going to see the market revival very soon.

How has the market responded to your recently launched Prima LX range?

Prima LX has received very good response from the market. We were trying to make a new value proposition with the Prima where a world-class truck will be affordable for everyone. Secondly, we wanted to bring the Prima into the mainstream multi-axle segment which accounts for nearly 60 per cent of the industry. Around six LX tractor variants and six LX tipper variants are already in the market, with the multi-axle truck having taken some more time since it is a new segment for the Prima. We started production of the 25-ton multi-axle Prima LX truck in October and will start rolling out the 31-ton version by January. By then, the market will see Prima unfolding in a big way because these vehicles (multi-axles) have a larger share in the industry.

While taking a test drive, I did not find much difference between the drivability of the Prima and the Prima LX. How is the LX different from the earlier version?

The off-road test track, located slightly away from the plant, is used to simulate real life environment such as in mines and quarries, for testing closer to actual situations, including collection of Road Load Data (RLD)

That is exactly the kind of response we wanted from our customers. In fact, the biggest challenge which we took upon ourselves is that people should not find any major difference between the Prima and the Prima LX as it would dilute the Prima brand which is a platform known for its reliability and quality in terms of cabin, frame, aggregates and drivability. We have actually added cost in some areas in the LX, like offering a metallic front bumper instead of an SMC one, so that it can be replaced easily in case it gets damaged.

The axle has undergone a change, with the LX fitted with a single reduction axle, while the first version of the Prima had a hub-reduction one as standard. Also, the 230 hp engine in the LX offers lower engine cost and better fuel efficiency for customers. There are certain other features such as cruise control, power window, HVAC and the CD system which have been made optional in the LX as not all customers wanted them.

As far as pneumatic seats, power steering, factory-fitted telematics, safety features and NVH levels are concerned, they are all the same as between the two versions. On the whole, the performance, safety, comfort, reliability and quality of the Prima have been retained in the LX range.

What else are you working on at present?

As showcased at Auto Expo in New Delhi, we are making a big upgrade in our current range of trucks, and this will be introduced in Q4 2014. There are changes such as extended warranty and longer drain intervals which we are doing across our entire range as they have an immediate impact on customers’ perception of our quality and also on their operating costs. In both our regular platform and the Prima range, we will continuously work on improving fuel efficiency and reducing the cost of maintenance and operation. We will also increase the service intervals to ensure vehicles do not come to the workshop often.

Another aspect we are working on is around connected vehicles through our tie-up with Microlise. Our Fleetman telematics device gives the fleet operator basic details on vehicle tracking and fleet management. Going forward, we will introduce a lot more features to help customers operate the vehicle more efficiently and make driving more comfortable, resulting in fuel efficiency improvement of nearly five to seven per cent. Another area we are exploring is remote diagnostics and prognosis which will help reduce the downtime and repair cost by predicting the failure of aggregates in advance. This is a common technique internationally, and we are aggressively working on it as well.

Lastly, how do you plan to maintain your market share in the M&HCV segment?

In terms of technology, not to be complacent and over-confident, we think we have what it takes to face competition, and we are always one step ahead when it comes to the Indian market. As long as we are able to connect with the customer properly and cater to his changing needs with regard to services and solutions, I think we are fairly confident that if we get our act together, as we did all these years, there is no reason why we should not maintain our market share.

————————————

|

On behalf of Henkel Adhesive Technologies, I would like to extend my heartiest congratulations to the entire team of Tata Motors on achieving yet another milestone. Best practices in corporate governance can only emerge when informed by an established set of business principles and a defined approach towards organisational behaviour, and Tata Motors has proven it right with every innovative initiative. With the successful maxim of ‘leadership with trust’, Tata Motors has not just given the country its due pride but has ensured to touch the hearts of millions in India through their wonderful products and services. We feel proud to have a wonderful working relationship with a company like Tata Motors for so many years, and we wish the company many more such successful years ahead. – Mr. Manish Dave, Business Director – Transportation & Metals Group, Henkel Adhesive Technologies India P. Ltd. |

|

Our congratulations to Tata Motors on its completion of 60 graceful years of trust. We have the pleasure of being associated with this great institution for over 21 years. It was the then Telco’s impressive product line-up, which enjoyed customer appeal and broad acceptance, that attracted us to their fold initially. They have always had the pulse of the market at their fingertips and a very good understanding of the market requirement, together with the employment of a quick and positive response mechanism to the feedback of discontent of their customers and other stakeholders; which has led them to consistently churn out products that are game-changers in every segment and earn customer goodwill worldwide. The brand is synonymous with the ethical and transparent business practices and has been a role model of corporate governance. We have grown together in an atmosphere of mutual trust, and this has been a great learning experience in upholding ethical values and how to reach out to the customers and the employees for their ultimate satisfaction. We have been particularly touched by their customary practices of reaching out and extending a helping hand to all stakeholders at the time of crises. There are cycles of peaks and troughs that the businesses go through, and we have had the fortune of particularly been supported by this great institution during crises. We cherish our relationship with Tata Motors and wish to achieve many more milestones together in the days ahead. We also wish them success in all their future endeavors. – Mr. Vijay Gupta, Director, Matsya Automobiles Ltd. |

|

I am really very pleased to hear that you are bringing out a special edition in December 2014 on Tata Motors Ltd. We have been associated with the venerable TML for the last many years and cherish every moment of it. All our employees and technical staff join me in wishing a grand reception for the forthcoming issue, and I am sure that you and your organisation will be bringing us and TML in close synergy. – Mr. Ankit Agrawal, Vice-President, Shree Balaji Engicons Pvt. Ltd. |

————————————-

|

Jasper’s Tata commercial vehicles dealership started functioning in Vijayawada in 1955. It was among the first dealers to be appointed by Tata Motors there. The 1955 slogan of Tata trucks, ‘Breadwinner of the family’ remains true to this day, and Tata trucks are really breadwinners for millions of families. Jasper is proud of exclusively dealing with Tata Motors for the last 60 years and is honoured to be partner with an industry leader that has made channel partners grow together over the years. On this glorious occasion of 60 years of truck manufacturing at Jamshedpur, Jasper expresses its gratitude to Tata Motors and wishes all success for it in the years to come. – Mr. Sumanth Badiga, Jasper Industries Pvt. Ltd. |

|

Harita Seating Systems Ltd. (HSSL) is a major supplier of seating systems to Tata Motors Ltd. (TML), both for domestic requirements and exports. HSSL has successfully developed products meeting the requirements of Tata Motors, with its driver, co-driver and passenger seats highly acclaimed for quality and comfort. In 1996, HSSL commissioned a plant in Ranjangaon exclusively to service the seating requirements of TML. It has developed several types of seats for the 207, 407 and 608 models. The company has also worked with TML for developing seating applications for various models of its vehicles including: * Seats for low-floor buses: When TML wanted to introduce high-capacity, low-floor buses (RESLF & HCBS) for city bus application, HSSL could readily supply a unique plastic seat design from its product range. * Seats for export vehicles: For TML’s buses for the export markets (primarily made at ACGL), HSSL had developed several designs which were successfully implemented to meet the specific needs of different markets. * Web seats: The company has also has developed low-cost web seats with height adjustment, sliding and reclining movements for the drive away chassis that meets the latest Automotive Industry Standard for seating systems (AIS-023). Besides ensuring safety, these seats also facilitate free airflow to provide riding comfort to drivers during summer. |

|

Congratulations to Tata Motors Ltd. (TML) on completion of its 60 years of dedicated service to the nation with safe, cost-effective and reliable commercial vehicles. It was more than an experience worth to be associated for 35 years servicing with prototypes and regular supplies of auto ancillary components. We have seen many leaps and transformations in TML over the years. With the new government at the Centre and the recent collective rise of the core sectors such as the coal, mining, energy and refineries, we are certain that the CVBU division of TML, especially the world truck Prima, will soon get to stretch its muscles further. We extend our best wishes to all the members of Tata Motors to achieve many more milestones in future. May the Diamond turn into Platinum. – Mr. R. Seal, CEO, Walia Auto Ancillaries Pvt. Ltd. |

|

I am very happy to note that Tata Motors, a leading brand of commercial vehicles, has completed 60 successful years. I wish Tata Motors all the very best in their present and future endeavours. – Mr. Chandrashekar Viswanath |

|

Over the years I have been to various Tata establishments, and each time I have had good interactions with the people and felt good that here is a Group which is doing our country proud. In this context, I specially remember a meeting I had had at Tata Scientific Services Division in Jamshedpur some 6 to 7 years ago when I met Dr. V.V.V. Subramanya, Chief of SSD. I had gone to introduce the spectrometers we had developed for the first time in Bharat. Dr. VVVS organized a meeting in their large Conference room, and I gave a presentation. At the end of it, Dr. VVVS and his colleagues got up to applaud this new development for our country, and each one of them came to shake hands with me! That was a special moment. Of course, it was early years for us. Dr. VVVS wanted certain developments to be made by us, including the analysis of very low carbon (EDD) steels. He assured that as soon as we did this, they would be one of our buyers. We have now made most of these developments. Today, after a decade of selling our first spectrometer in Bharat (in 2004), we are proud to state that the Tata Group is already using two of our spectrometers; we have several users in Jamshedpur where most of them are suppliers of products and services to the Tata Group. We also have over 1,000 users wordwide! The way has been tough and we have had our share of setbacks. But, overall, it has been very satisfying. We believe that “if a thing is worth doing at all, it is worth doing well” and also that “We must go by the basic principles of life which are common to all walks of life – yes, Business too!” Business is only part of life, it is not life itself. On behalf of Metal Power Analytical (I) Pvt. Ltd., I take this opportunity to congratulate Tata Motors on their 60th anniversary of service to the nation. We are proud and honoured to be associated with them over the last few decades. We congratulate them on this special and historic milestone that has seen them maintain Leadership in Commercial Vehicles in Bharat and wish them well for the future. – Mr. P.D. Pant, CMD, Metal Power Analytical (I) P. Ltd. |

|

Interpump Hydraulics Pvt. Ltd. (IPH) is hand in hand with Tata Motors for power take-off (hydraulic) technology. In the earlier days, the tipper segment used to be manually loaded, and hence there was no need for any hydraulic technology. However, when mechanisation and development started in the segment, the tipper was upgraded with the use of hydraulic technology for tipping, giving it the advantage of lesser tipping and loading time. The hydraulic technology mainly comprises a power take-off, a pump and a hydraulic cylinder. IPH is the world leader in this technology, and Tata, being the leader in the country for commercial vehicles, the association with the leader was bound to happen. IPH started working with Tata Motors since 2007 by giving the first power take-off to one of its transmissions. Now, over the years, this association has turned into a very good partnership, giving the latest in technology to the country. ‘It is an honour and pleasure to work and get associated with Tata Motors. It is a relationship of mutual benefit which has been developed over the years, and together we are giving the latest technology available in Europe to the Indian customers. The relationship has changed from a customer-vendor one to a partnership, and IPH is proud to be a partner of Tata Motors. The transparency, positive approach and helping attitude of all Tata Motors employees towards us is worth fully appreciation, and it helps us to establish products with the latest technology in the Tata range. We are proud to be associated with Tata Motors, and we wish them all the best for the future. – Mr. Girish Garud, MD, Interpump Hydraulics Pvt. Ltd. |

|

Parmar Transport Company is a reputed organisation operating in the field since last 60 years. We are one of the first buyers and users of the Tata range of commercial vehicles ever and continue to patronise the company products. Our fleet today comprises primarily of Tata vehicles of different models and capacities. The quality and range of products, the wide network of service stations, the personal touch and high levels of efficiency and customer service exhibited by Tata Motors personnel and dealers have ensured that we have never had to look beyond Tata Motors for our requirements. – Mr. Jagjit Parmar, Partner, Parmar Transport Co. |

|

Rane Group has partnered Tata Motors since many decades with our strong relationship being built on shared values and ethics. Rane started its association with Tata Motors by serving its Commercial Vehicle business and today supplies products for its passenger cars and MUVs as well. Today, Tata Motors is among the top customers for Rane and going forward, we only see this mutually beneficial partnership strengthening further. On this occasion of 60 years of Tata Motors’ Commercial Vehicle Division, we would like to congratulate and wish them the best for more success to come, assuring them of our commitment and support as one of their key suppliers. – Mr. L. Ganesh, Chairman, Rane Group |

|

Pacoline congratulates Tata Motors Ltd. (TML) on completing 60 years of leadership in trucking. Pacoline has grown with TML in the last 40 years and it was only because of their trust in Pacoline’s engineering capability and capacity, the development of rear view mirrors commenced followed by supplies to TML. Pacoline supplies a large variety of assemblies, plastic components , warning triangles and mirror assemblies to TML to almost all its plants and vehicle range, right from their small commercial vehicles to medium and heavy trucks and buses. Tata Motors’ approach and the trust it shows towards its vendors is commendable. They have a very transparent approach right from the development stage, negotiations and till the commencement of supplies. We believe to go further ahead with the experience gained in working with them over the years and with the hand-holding and rock-solid trust of Tata Motors in the years to come. Working with the Tata brand for the past nearly 25 years has made us bag orders from other domestic and global vehicle manufactures as well. – Mr. Muzammil Shaikh, Director, Pacoline Industries Pvt. Ltd. |

|

We attribute our success to the unmatched lessons we have learnt from Tata Motors. It is certain that a well-diversified group like the Tata Group will be an example for millions of Indians. The innovation, design, sales, production and penetration by Tata Motors not only in the Indian market but also at the international level deserves applause. We take this opportunity to wish the entire team of Tata Motors great success on the occasion of their Diamond Jubilee and many more milestones to be achieved in the future. – Mr. Suresh Kumar Arora, Managing Partner, KKTC, on behalf of the KKTC-FUWA Team |

|

Tata Motors commercial vehicles have been a catalyst towards goods movement, rapid development of infrastructure, seamless people transportation and even last-mile transportation in India. From providing safe transportation means for our brave soldiers on the border to making sure that milk reaches our homes fresh and clean every morning, Tata Motors truly has a vehicle for all possible applications. It is due to such innovation and reliability that the company commercial vehicles unit has stood the test of time and will continue to do so for many more years. We at Pandit Automotive have been associated with Tata Motors as dealers since the past 58 years. We are proud to state that we are part of their close-knit family and through our humble efforts have also contributed in our own small way to this legendary success story. – Siddhartha Gokhale, Executive Director, Pandit Automotive Pvt. Ltd. |

——————————-

MAJOR MILESTONES IN THE SIX-DECADE JOURNEY

Tata Motors celebrates 60 years of trucking excellence

|

—————————————