By Dr. Raj Shah, Koehler Instrument Company, Holtsville, NY, and Shailendra V. Gokhale, Rosefield DAA International Consultancy LLP

The automotive industry has been patiently awaiting ILSAC GF-6, a new engine oil category for passenger vehicles and light trucks in the United States. The establishment of GF-6 has been a long and difficult road plagued with delays due to the unprecedented number of new engine tests and seemingly endless complications. Finally, on April 3, 2019 Automotive Oil Advisory Panel (AOAP) meeting, stakeholders agreed on final test limits, and the first release has been balloted as of May 1, 2020. The new ILSAC specification comes in two parts, GF6A for legacy viscosity grades and GF6B for SAE XW-16 oils. ILSAC sets the minimum performance standards. SAE determines the requirements of engine oil specifications based on automaker inputs and market trends. ASTM develops tests and parameters for each specification provided by SAE. Finally, API licenses and certifies the engine oils.

Reasons for GF-6

ILSAC GF-1 through GF-4 have made incremental ameliorations to fuel economy and lubricant efficiency; however, the current GF-5 standard has made significant advances. This tempo adjustment coincides with the Corporate Average Fuel Economy (CAFE) legislation issued under the Obama Administration in 2010. Consequently, a biphasic national program was installed. Phase I encompasses passenger vehicles between the model years (MY) 2012-2016 and Phase II concerns MY 2017-2025. By the year 2025, passenger cars and light trucks must attain an average fuel economy of 54.5 mpg. Hence, the upcoming ILSC GF-6 standards will be very stringent to accommodate the Phase II objectives. The demand for continuous lubricant innovation is twofold. Firstly, lubricants must adapt to work with newer engine technologies. Secondly, lubricants themselves contribute to fuel economy. OEMs are exploring every avenue to meet the Phase II CAFÉ goals. Typically, lubricants tend to improve fuel by only as much as a paltry 3%, in contrast with light-duty vehicles producing 60% of greenhouse gas (GHG) emissions from the U.S. transportation sector, there is significant GHG emission reduction potential7.

Aside from legislation, advancements in engine technology require complimentary lubrication. In the past few years, gasoline direct injection (GDI) and turbocharged gasoline direct injection (TGDI) have taken the market by storm. Approximately 50% of all MY 2017 cars and light trucks have GDI technology, and that number is steadily growing6. Compared to traditional port fuel injector engines, GDI engines directly inject gasoline into the combustion chamber. The smaller form factor and better fuel economy are responsible for its popularity. TGDI engines are notably fuel efficient because they introduce more oxygen into the combustion chamber. However, the higher performance and temperature may cause the engine oil to deteriorate more quickly. In addition, GDI engines are prone to elevated fuel dilution in the ring pack oil. Herein lies the need for upgraded engine oils over the GF-5 standard.

Now that there is an influx of TGDI engines on the market, there is a pressing need to solve low-speed pre-ignition (LSPI). LSPI is an event in which combustion of the fuel-air mixture occurs, prior to the spark ignition, when the engine operates at low speeds and at high loads. This phenomenon differs from conventional engine knock because LSPI is unpredictable and more damaging with potential piston cracking, but improvements to hardware design, fuel formulation, lubricant composition and engine control management strategies can curb LSPI4. One theory hypothesizes that an oil droplet is expelled from the top ring groove, then enters the combustion, mixes with fuel, and prematurely ignites. Yet another theory elucidates that piston deposits may be the agent causing LSPI. Thus, LSPI prevention is one of the primary objectives of ILSAC GF-6.

Another issue with TGDI engines is a high level of particulate matter. This is a shared characteristic in common with diesel engines due to the fuel being directly injected into the combustion chamber. The soot production and oil degradation can lead to timing chain wear culminating in decreased performance, higher emissions and potentially costly repairs.

Thinning engine oils is an ongoing trend because of the fuel economy advancements. However, this inclination causes some concerns. Temperature’s effect on viscosity is well documented. At operating temperatures, the engine is protected from friction and wear by a thin oil film. However, if overheating occurs, the thin oil film will degrade and could conceivably result in devastating wear to the engine. Another disadvantage of thinner oils is that abrasive soot and wears debris particulate matter, equal to or greater than the thickness of the oil film, will cause wear4. This underscores the importance of oil filters to prevent wear debris from entering the oil film. As the thin oil trend continues, ILSAC GF-6 must implement standards which balance both engine performance and robustness.

ILSAC GF-6

ILSAC GF-6 addresses many issues where ILSAC GF-5 was lacking. First and foremost, fuel economy and fuel economy retention are imperative as Phase II CAFÉ deadlines are fast approaching. The prevalence of TGDI engines calls for a focus on turbocharger deposit control-chain wear protection and LSPI prevention. Furthermore, engine durability and wear protection for idle-stop will also be augmented.

ILSAC GF-6 is the first ILSAC GF standard to have two subcategories: GF-6A and GF-6B. The two subdivisions are virtually identical with one pivotal difference. ILSAC GF-6A will be backwards compatible with GF-5, but GF-6B will not. It will also accommodate engine oils with viscosities SAE 0W-16 and lower. Overall, there is almost no distinction between GF-6A and GF-6B, barring the slight increase in fuel efficiency in the latter subcategory. This is to be expected because low viscosity engine oils have proven to increase fuel efficiency.

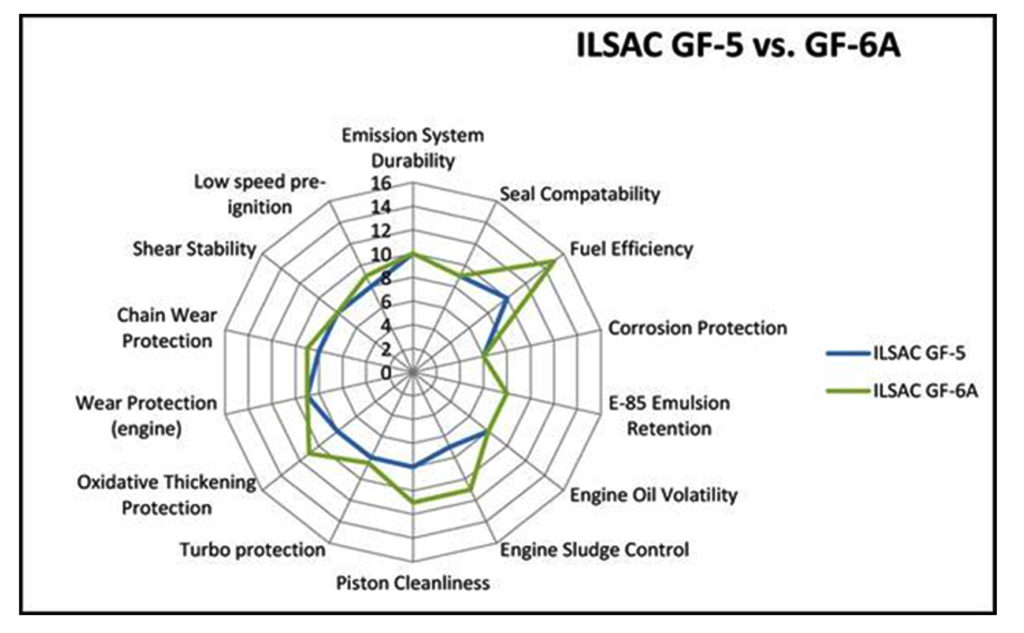

Figure 1. Spider web diagram comparing ILSAC GF-5 and GF-6A3

Engine Tests

ILSAC GF-6 is the first standard to incorporate six new tests. Four of which are replacements, two are entirely new and one test is carried over from GF-5. There is a total of eight engine tests. Each of these tests is meant to address a specific issue like LSPI or to meet requirements such as improved fuel economy.

Sequence IIIH (replaces IIIG)

The objective of this test is to measure lubricant thickening, oil consumption and piston deposits under high-temperature conditions. It was developed to simulate high-speed engine operation under relatively high ambient conditions. The engine used is a Chrysler 3.6L V-6 Pentastar fuel-injected gasoline engine.

Sequence IVB (replaces IVA)

The objective of this test is to evaluate the effect of an automotive lubricant on tappet wear for engines using direct-acting overhead cam-valve trains. A Toyota 2NRFE 1.5L fuel-injected, inline four-cylinder engine with dual overhead cam shafts and four valves per cylinder is used.

Sequence VH (replaces VG)

The objective of this test is to evaluate the performance of a lubricant in controlling low-temperature engine deposits under operating conditions deliberately selected to accelerate deposit formation. The test was designed to simulate moderate-temperature taxi service, urban and suburban delivery service and commuter service. The test runs for 216 hours and has 54 cycles, each cycle consisting of three different operating stages. The fuel used contains a sludge precursor and engine blow-by is intentionally increased.

At the end of the test, sludge deposits rated for the rocker are on the covers, rocker arm baffles, timing chain cover, oil pan baffle, oil pan and valve decks. Varnish deposits are also rated for the piston skirts on the thrust side and the rocker arm cover baffles. Clogging of the oil pump screen and piston oil rings are also rated along with the piston compression rings rated for hot and cold sticking.

Sequence VIE (replaces VID) / VIF (new)

The aim of both these tests is to provide a comparative fuel economy index (FEI) of the fuel-saving capabilities of automotive engine oils under repeatable laboratory conditions. The test duration is 196 hours, and fuel consumption is measured for six speed/load/temperature test conditions compared to an SAE 20W-30 baseline lubricant. The test lubricant is introduced and aged for 16 hours before the first set of measurements are taken. The second set of measurements are taken after a further 109 hours of aging.

Sequence VIII (legacy test)

The objective of this engine test is to evaluate the performance of a lubricant in preventing copper/lead/tin bearing corrosion and to measure viscosity shear stability under high-temperature operating conditions using unleaded gasoline. Test duration is 40 hours with the engine running at 3150 rpm and with a lubricant temperature of 143°C. Lubricant samples are taken and tested for viscosity at 10, 20, 30 and 40 hours.

Sequence IX (new)

The objective of this test is to check oil formulations for tendencies to promote low speed pre-ignition (LSPI) in turbocharged direct-injection engines. It uses a 2.0 L inline four-cylinder Ford EcoTech engine with two overhead camshafts which operate two intake and two outlet valves per cylinder. The engine runs in four-hour segments, totaling 16 hours. Each four-hour increment is 175,000 ignition cycles. At the end of the 16 hours, the number of LSPI events are counted for each of the four segments and an average number obtained.

Sequence X (new)

The goal of this test is to measure timing-chain wear to validate anti-wear capabilities of lubricants. It uses the same Ford EcoTech engine as the Sequence IX test. Subsequently, the engine is run for a further 208 hours after which the chain is again removed, and its length measured. The chain stretch is then reported as a percentage.

The time has come

The beginning of May 2020 is now here, heralding the official licensing date for the much-touted ILSAC GF-6A and GF-6B motor oil specifications, in addition to the supplementary API SP specifications. This is the final installment of what has arguably been the most challenging specification goal which has been achieved. The last loose ends were wrapped up at the end of June 2019. This coincided with the ballots for the Sequence IVB test, which went through APIs Lubricants Group uncontested.

It would also be interesting to look at another huge Automotive market like India, in terms of adoption of ILSAC GF-6. Typically, the Indian market has adopted new oil specifications with considerable lag. However, the situation has completely changed in last 4 years. In 2016, Indian government unveiled its ambitious plan of migrating from BS IV (equivalent to Euro IV) to BS VI (Equivalent to Euro VI) by 1st April 2020. This was going to be a big challenge for OEM industry in India. However Indian Automotive Value chain, comprising of Fuel refineries, Automotive OEM, Lubricant companies and additive companies, achieved this feat much ahead of 1st April 2020. This has built a strong confidence among stakeholders in India, including policymakers and we think that such ‘can do’ approach will encourage India to adopt ILSAC GF-6 as soon as possible.

Acknowledgements

The authors sincerely wish to thank Dr. Peter Lee from Southwest research institute for his assistance in editing the manuscript. His input was invaluable in completing this article. The authors also thank Dr. Mihir Patel from Chevron, for his initial review, and Dr. Bill Anderson from Afton Chemical for his final corrections and comments which further improved the article.

References

https://www.oats.co.uk/resource-centre/wait-over-gf-6-and-sae-16-japan-goes-further

https://www.infineuminsight.com/en-gb/articles/passenger-cars/ready-for-ilsac-gf6/

https://www.sae.org/publications/technical-papers/content/2019-01-2240/

https://koehlerinstrument.com/wp-content/uploads/2019/10/103_ILSAC-GF-6-GCC-2019.pdf

1Modern Technology of Petroleum, Greases, Lubricants & Petro Chemicals. 2nd ed., Publication Division, National Institute of Industrial Research, 2008.

2https://www.oilspecifications.org/ilsac.php

3https://www.motor.com/newsletters/20131121/WebFiles/ID_AdvancedLubes.html

4https://www.machinerylubrication.com/Read/518/motor-oils

5https://www.oronite.com/products/lspi.asp

6https://www.energy.gov/eere/vehicles/articles/fotw-1018-february-26-2018-about-half-all-new-cars-and-light-trucks-have

7https://www.epa.gov/greenvehicles/fast-facts-transportation-greenhouse-gas-emissions

8“Sequence VIII Test.” Southwest Research Institute. https://www.swri.org/sites/default/files/sequence-viii-test.pdf

9“Sequence VIF Test.” Southwest Research Institute. https://www.swri.org/sites/default/files/sequence-vif-test.pdf