By KVR Babu, President, and Sudipto Basu, Executive Director, ECMA

With the ambitious plan for emissions reduction from automotive sources in India, there is now a need to look carefully at the options that are available to automotive and engine manufacturers to meet the future stringent emissions requirements.

The emissions control manufacturing industry in India, represented by ECMA, has currently 15 member-companies manufacturing a large number of exhaust aftertreatment solutions and components that shall help OEM achieve these norms in future.

Fossil-fuelled vehicles, although under threat from the disruption expected from electric prime-movers sometime in the future, still have to run cleanly, using appropriate aftertreatment till alternatives overtake their use. For the two types of fuel used principally, gasoline and diesel strategies differ as the industry moves towards a cleaner environment.

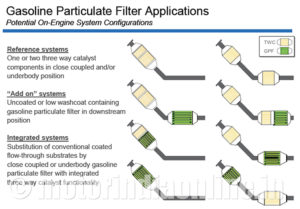

For gasoline (petrol) powered vehicles, although hydrocarbon and carbon-monoxide control can be achieved with a three-way catalyst, not much different from what is used currently, the principal requirement is expected to come from control over very small particulate emissions (even < 2 microns). This shall be achieved with Gasoline Particulate Filters (GPF). The accompanying picture shows the various configurations of GPF that shall be used.

For compressed natural gas (CNG) or liquified petroleum gas (LPG) fuelled vehicles too the concern would be very fine particulate matter and for this too GPF shall be required.

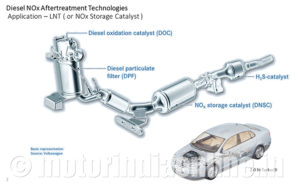

For diesel-fuelled passenger cars, the emission control system, though more complex than with gasoline or CNG/LPG, emissions control is equally effective with properly engineered aftertreatment solutions.

A typical application of the options that shall be available for particulate matter and NOx control is illustrated here:

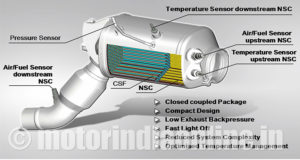

For passenger car Oxides of Nitrogen (NOx) control, Lean NOx Trap (LNT) or NOx storage catalyst (NSC) as displayed shall be the predominant solution. Although not as efficient as Selective Catalytic Reduction (SCR) the low bulk of LNT, compared to SCR as well as the ability to operate at lower temperatures, make this the preferred solution.

The details of a NOx storage catalyst:

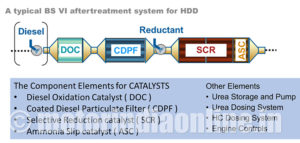

Moving to heavy duty engines used in trucks and buses (as well as for tractor and off-road applications), the principal strategy in future shall be a combination of DOC, DPF and SCR, including an ammonia slip catalyst. A typical configuration representing this is as illustrated here:

For India, the important considerations are the achievement of temperatures required for efficient operation of SCR in the very varied operating conditions seen in applications. For example the same truck may operate within cities where roads are congested and traffic start-stop or slow, leading to low temperatures that the inhibit the efficiency of aftertreatment devices.

Again, the same truck could be running inter-city and therefore the aftertreatment has to be engineered so that emission targets are met in both types operation.

This means that the aftertreatment elements, (DOC, DPF and SCR) have to be chosen keeping in mind the application requirements and a host of combinations are available from the ECMA companies. Different ranges of size, shape and material for the substrate as well as different types of coating for DOC, DPF and SCR technologies capable of meeting these challenges have been developed over the years.

Typical options that shall be available for SCR are for substrates, coated or extruded, or even metallic monoliths. SCR coatings, either Vanadium, copper or iron-based exist, each having slightly different properties, to suit various types of applications and of course also cost!

This brings us to the all-important cost aspect, as the Indian market is both cost and quality conscious, and although performance requirements per-force require that appropriately engineered architecture and materials have to be used, ECMA member-companies have the additional consideration for providing affordable solutions for India.

Sudipto Basu appointed ECMA Executive Director

Mr. Sudipto Basu has been appointed Executive Director of the Emission Controls Manufacturers Association (ECMA) operating from Delhi. He suceeds Mr. B.R. Gosain who had been instrumental in building up ECMA to the level of recognition and competence that it enjoys today.

A Mechanical Engineering graduate from IIT Kanpur, with special interest in engine and powertrain, Mr. Basu has been working in the automotive industry for over 40 years in different capacities.

He started his career at Tata Motors (then TELCO), Pune, in 1976, and worked in the Engineering Research Centre, developing and testing engines for Tata vehicles. During his 25-year stint at Tata Motors, he was instrumental in developing and getting Tata products certified for emissions at ARAI and later at European test agencies, as Tata began its thrust on exports to Europe.

Moving to a techno-commercial function in 2000 at AVL India, Mr. Basu was responsible for acquiring business for powertrain development for AVL Graz and for the AVL Technical Centre, in Gurgaon.

After having worked in engine development he moved to aftertreatment with Umicore Automotive catalysts in 2005 and was responsible for building the Indian market for Umicore, so that its catalyst facility in Pune could be commissioned.

Widely recognised in the automotive fraternity, at OEM as well as test agencies and engineering service providers, as a knowledgeable and resourceful person, Mr. Basu has been tasked several times as trouble-shooter, successfully resolving issues innovatively.

Now, with the very strong focus on technology and development for the stringent emission expected form fossil-fuelled vehicles and engines, a technically oriented person was required at the helm at ECMA. With vast knowledge and experience in powertrain, automotive emissions and regulatory framework globally, Mr. Basu was seen as the right candidate to head ECMA.