Speech by Dr. Eckhard Scholz, CEO Volkswagen Commercial Vehicles

Today, I would like to show you the influence customer focus has, on the attitude of our most important customer groups and on the development of light commercial vehicles for these customer groups and the new approaches we are utilising in our development activities. I will use our new Crafter as an example to explain the latter aspect. This vehicle will celebrate its world premiere at the IAA Commercial Vehicles Show in Hannover this coming September. Before I get to that, I would like to talk about what customer focus actually means.

Those who wish to know what a customer really wants to get out of their Transporter need to work closely with their customers.

Commercial vehicle customers essentially have different and usually more extensive requirements than customers who purchase a passenger car. Light commercial vehicle customers expect their product to deliver an optimal solution for their daily business at the lowest possible cost, at a high level of quality and with outstanding service as well. Customers in this sector do not base their purchasing decisions on emotions the way people who buy a car for their own personal use do.

The relationship between our brand and its customers has grown over the last 70 years and is also constantly changing. One thing remains the same. Our advertising poster from the 1950s says “VW Transporters help you earn money”. This is the basis of our entire customer focus. The idea at that time was to provide customers with a robust and technically reliable vehicle that would serve as the foundation for their business. We would retain such customers for years by performing maintenance on their vehicles or by supplying them with spare parts and from time to time we would also offer them more modern vehicles or additional vehicles, which made both of us happy.

Since the 1950s, the right vehicle for this approach has been the Volkswagen Transporter. Our classic model had an exterior length of approximately four metres, a cargo volume of just under 5 m³, a payload of one tonne and a gross vehicle weight rating of 2.8 tonnes. The “pack mule” of Germany’s economic miracle offered optimal transport capacity with a low space requirement and outstanding space utilisation. Whereas products used to be relatively homogeneous and were often used by customers as buses and delivery vans for both private and commercial purposes, the days of such dual use are now over for most commercial customers. Instead, vehicles are now tailored to the specific applications customers use them for. The goal here is to offer customers the sector-specific yet also individual solution they need to do their jobs with a fair price-performance ratio, nothing more and nothing less.

Commercial customers focus on the bottom line: “How much does it cost me to drive my vehicle one kilometre?” The purchasing decisions made by commercial customers are based on the principle of cost effectiveness. This means the sum of all costs across the entire life-cycle of the transporter, from insurance and maintenance to value losses and operating costs, and even the vehicle’s resale value. We refer to this in the automotive industry as TCO, or total cost of ownership. Every cent counts here, especially when your fleet consist of 20 or even 100 vehicles. Improving TCO, which is an indicator of cost effectiveness, has therefore always been extremely important to our customers.

However, these days customer focus also means knowing exactly what the most diverse customer groups generally want from their vehicles.

Here you can see our eight most important customer groups. Regardless of whether these customers are courier services companies, tradesmen, taxi drivers or government agencies, they all agree that commercial vehicles are investment goods that are used like tools, the reliability of one’s “tools” is the top priority, vehicle downtime generates high costs and restricts business operations, requirements regarding cargo-space design and load restraints vary even within individual customer groups, which is why a high level of flexibility is important and vehicles are often driven by different drivers who use the same cab workspace.

Customer focus also involves the provision of assistance systems that support drivers in their daily work and help them deal effectively with traffic flows that are becoming more complex every day. Our models today already include numerous driver assistance systems that make driving safer, more ergonomically sound and more efficient. Such systems include Emergency Assist, Traffic Jam Assist and Trailer Assist. Light commercial vehicle customers are increasingly demanding all of them because they protect the customer’s most important asset, the driver, and the second most important asset, the vehicle.

Emergency Assist recognises if the driver is no longer responsive. It uses various escalation stages to wake up the driver by shaking him/her and will then bring the vehicle to an emergency stop if necessary. Traffic Jam Assist uses the automatic Adaptive Cruise Control system (ACC) and the Lane Assist system to enable partially autonomous driving in heavy traffic. Trailer Assist makes it easier to manoeuvre with a trailer by using a camera to analyse the angle between the car and the trailer, after which it calculates the steering angle on the basis of the analysis.

The A2 autobahn is the one of the most dangerous motorways in Germany. On this east-west artery, according to our l daily-newspaper research, there have already been 700 accidents and 22 deaths this year just on the 90-km A2 segment between Hämelerwald and the border to the state of North-Rhine Westphalia. Thousands of accidents that kill people and damage vehicles could be prevented if effective driver assistance systems were to be installed systematically in heavy-duty and light commercial vehicles.

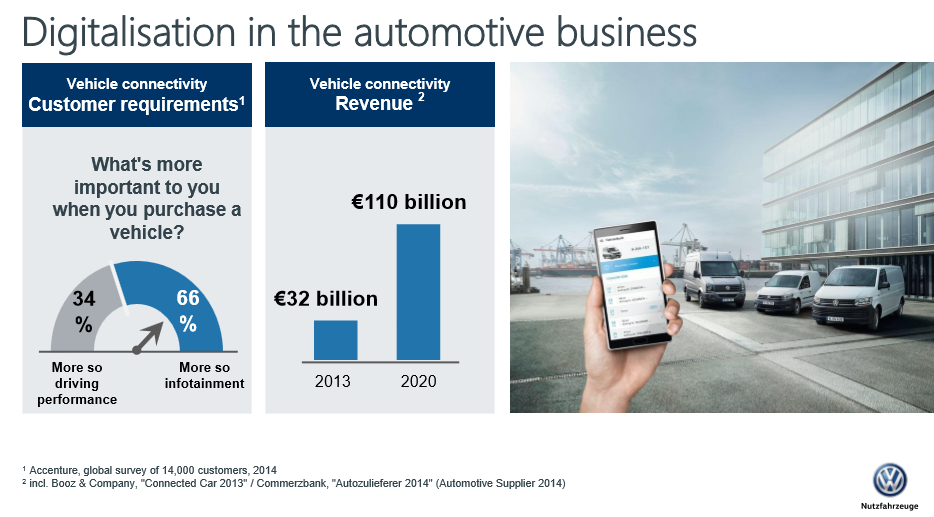

Our world is changing at an ever-faster pace and has become almost completely networked. “Digitalisation” is the buzzword today, and with light commercial vehicles as well the task is to develop intelligent solutions and services along the entire value chain. We need to improve vehicle capacity utilisation and reduce downtime. Digital innovations offer entirely new possibilities here with systems that can significantly increase the efficiency of our customers’ operations and which also offer real added value in terms of sustainability and safety in the provision of goods and services. Customers have a clear idea of what they’re looking for when they purchase a new vehicle. PS and torque are not as important here as having a system that links smartphones to the on-board network in just fractions of a second to ensure the driver can gain unlimited access to the Internet.. Revenue generated with vehicle connectivity features will increase to €110 billion between now and 2020 alone.

The light commercial vehicle is increasingly becoming an office on wheels. Ergonomics, cab spaciousness and low noise levels in the interior are key requirements for all customer groups today. A connection to the home office via a tablet computer is obviously a matter of course here as well.

We in the Volkswagen Commercial Vehicles world refer to this as our new “Connected Van” system: The DataPlug is automatically on board of all new LCVs, but also retrofitable. The fleet managing system has been tested since March with over 1,000 customers and is available since last week. It administrates fleet and driver, operates fleet consuming, gives the vehicles currently position, fills the driver’s log, notifies the next maintenance appointment and has many more features, all accessible via apps.

Undreamed of possibilities will result from even more powerful computers. Faster data connections, intelligent sensors and cloud solutions could make a major contribution to optimising traffic flows, reducing emissions and preventing accidents in future.

The light commercial vehicle of the future will be more efficient, more digital, more sustainable and more multifunctional than ever before, and will also display a higher quality. It will drive on electricity and in a few years will drive autonomously as well. It will be networked with the latest generation of wireless network technology and will always be completely up to date, thanks to continual software updates. It will also optimally exploit lightweight design and has a good relation between payload and traffic footprint.

As a commercial vehicle manufacturer, we should provide solutions for the customer’s vehicle fleet consisting of more than one manufacturer. The interfaces have to be brand-independent. Our advantage lies in the fact that we offer the kinds of special commercial solutions for that a software company for passenger cars customers cannot provide.

All of these innovations do in fact pose a challenge for our customer-focused approach that has evolved over decades and we need to successfully address this challenge. This also includes electrification that meets everyday driving needs. Currently, C02 discussions are being conducted between politicians and manufacturers. So far, we have all been talking solely about electrification and hybridisation. But the end user is still not at the discussion table. We will be equipping our next vehicle generations appropriately, but only if the necessary technology is available at reasonable prices and in suitable quality. If electric drive systems do not offer our TCO-oriented customers any competitive advantages, they will not buy them. What happens if our commercial vehicle customers decide that they do not want to travel with us down the path towards zero-emission driving? We need to get involved the drivers of the commercial vehicle very early in the development process before even the first prototype of a new vehicle generation is built.

This is exactly what we did with our new Crafter, we merged the product focus with a customer focus. In other words, we developed this vehicle from the point of view of the customer. So, how does this “development with the customer” actually work? Our engineers need to consider and incorporate all the political and social implications of urbanisation, transport, efficiency and sustainability when developing a new vehicle generation.

However, we went a step further with the planning and development of the new Crafter. Our sales organisation conducted hundreds of interviews with business and traffic experts and held three driving events with selected major customers. An extensive secondary market research was as well important here as was a direct, permanent and productive exchange with more than 900 customer-group representatives.

The new joint development process has resulted in new customer-focused transport solutions that offer the highest levels of economy and whose product attributes manifest themselves as unique selling points and best-in-class features in the new Crafter. Along with the key role played by economy, which allows our customers to earn good money and do their jobs properly, customers are also interested in safety, vehicle responsiveness, environmental compatibility and easy handling. Our new commercial vehicle generation is thus destined to enjoy a solid market launch.

In conclusion, I’d like to turn your attention to one of our most important customer groups in terms of sales, the courier and logistics sector.

This group can be divided into different sub-groups that have individual requirements. Let me give you an example: In inner-city courier services time is money. If a courier driver uses his or her sliding door 200 times a day, and this door closes precisely and quickly, which gives the driver a time gain of, say, three seconds each time the vehicle is loaded or unloaded, then the company will benefit from this.

“How much is three seconds really”? Actually, it’s an awful lot. Two hundred door openings and closings per day adds up to 600 seconds or ten minutes and to around 2,200 minutes or 36 hours over 220 working days in a year. If the fleet in question consists of several hundred vehicles, then this figure becomes an indicator that’s just as important as fuel consumption. For example, we asked the users directly how the driver workstation should ideally be designed, and I’ll now tell you what we came up with as a result. A 13-litre glove compartment that can easily accommodate a DIN A4 folder. A dashboard panel with three 12-volt outlets and audio and USB interfaces, storage bins for IPads and cup-holders and side storage bins that can hold a warning triangle, a torch and a water bottle. And the list goes on…

It’s a workstation that meets the requirements of all the courier drivers, it’s functional and ideal and offers everyday utility. As you can see, we transformed product requirements into solutions that we successfully implemented in our new Crafter in order to benefit courier services and logistics companies.

Among other things, the model features an eight-speed automatic transmission, an ergoActive swing seat, side guards, an electronic surroundings monitoring system and a body that’s pre-engineered for the installation of shelving units. All in all, we have developed a trailblazing vehicle concept for the CEP sector.

Our products are being transformed from commercial vehicles that transport cargo to networked workplaces on wheels that meet all of today’s and tomorrow’s customer requirements. The customer-focused approach is now centred on not only the overall functionality of the vehicle but also on the driver workstation as the focal point of a perfect digitalised tool. Here, maximum customer focus is closely linked with maximum innovative strength.

You can see for yourselves on the upcoming IAA, when we present the new Crafter as a world premiere.