Scania presented products and services at IAA that can contribute directly to improving bus and truck customers’ profitability. A broad range of Euro 6 engines is complemented by new items aimed at reducing either the customers’ operating costs or the environmental footprint of their operations – goals that often go hand in hand. Scania’s latest innovations can reduce diesel consumption by three per cent in long-haulage vehicles. And when it comes to buses, Scania Citywide presented its own hybrid technology.

Scania’s modularly constructed range of engines for buses and trucks is one of the market’s largest also within Euro 6. In independent tests, Scania has shown that fears of increased fuel consumption with Euro 6 have been unfounded, at least for Scania’s customers. For example, Scania’s inline six 13-litre engine with SCR-only aftertreatment has shown itself to be unbeatably thrifty in long-haul operations. In June Scania introduced an additional version with 450 hp that has the potential to reduce fuel costs by about one per cent.

“Today, all kinds of customers are chasing profitability by reducing operating costs, regardless if their business is about transporting goods or passengers,” says Henrik Henriksson, Executive Vice President at Scania. “We should consider Scania’s continuous hunt for reductions in costly drops of diesel, custom-made solutions and increased uptime in light of this. At IAA, we are introducing a range of innovations that further strengthen our customers’ business calculations.”

Scania has its reputation in the bus market for being a manufacturer that is always able to live up to both society’s and customers’ demands for environmental solutions. This means that the buses are both fuel-conscious and can run in principle on any commercially available fuel, thanks to an extensive engine range. Scania is now taking a step further and is expanding its offer with hybridisation, in combination with the possibility of running on 100 per cent biodiesel.

Advanced technology

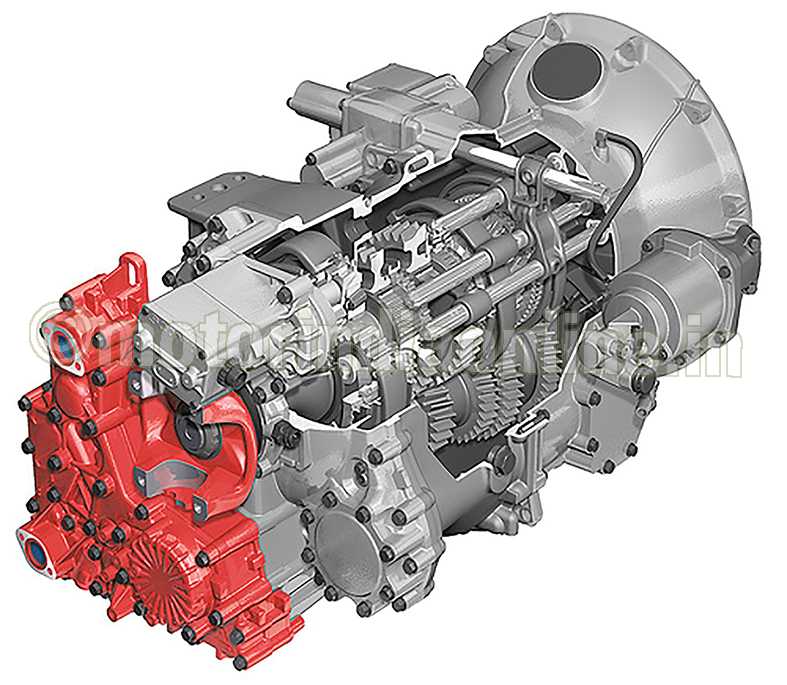

Scania also introduced a number of products and services at IAA to support the hunt for further fuel savings and increase uptime. Scania’s highly appreciated retarder can now be ordered in a version – R4100D – that cuts down on fuel consumption by mechanically disengaging when not active.

Besides saving energy, the freewheeling retarder also provides higher braking power, 4,100 Nm instead of 3,500 Nm, as well as an increased braking effect at lower speed with the help of higher gear ratios. Fuel savings are about an half per cent, in Scania’s experience. There is a further option that can be ordered that allows the retarder to be engaged only when the foot brake is used.

Scania showcased a further-developed version of Eco-roll, the advanced system in which Scania Opticruise, in combination with Scania Active Prediction, saves fuel. The vehicle itself is able to calculate when it is most advantageous to roll down slopes in neutral gear. Eco-roll can now contribute an additional half per cent in savings for Euro 6 engines in either buses or trucks.

Scania has also addressed the issues of reducing internal friction in some engines types. By raising the working temperature and using a specially developed, fuel-saving, low-viscosity oil with extremely good lubricating qualities, the company engineers have ensured a significant further savings potential of 1.5 per cent when the effects of increased temperature and the fuel-saving oil are put together. One reservation, however, is that this oil is only allowed to be used in long-haulage vehicles that have 13-litre Euro 6 engines and light operation classifications.

Customised solutions

“When it comes to sustainability, the European heavy vehicle industry, including buses, has just taken a critical step forward with the introduction of Euro 6,” says Christopher Podgorski, Senior Vice President, Trucks, at Scania. “The next step in developments is likely going to be reducing CO2 emissions, which we at Scania welcome. Lower fuel consumption is a game we excel at, and we feel like taking the challenge since we always have the customer’s profitability in view. The manufacturer who contributes to strengthening the customer’s total financial position will be the winner. Scania has the products, services and insights that are necessary for this role.”

Besides product-related news on buses and trucks, Scania presented a number of new or further developed services at IAA. Many of them uniformly aim to enhance customer performance by increasing uptime, which impacts revenues.